Patents

Literature

32results about How to "Good performance impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite micro-electro-mechanical system (MEMS) high-temperature resistant ultrahigh-pressure sensor

InactiveCN102012288ALower requirementHigh resistance coefficientForce measurementSignal-to-noise ratio (imaging)Engineering

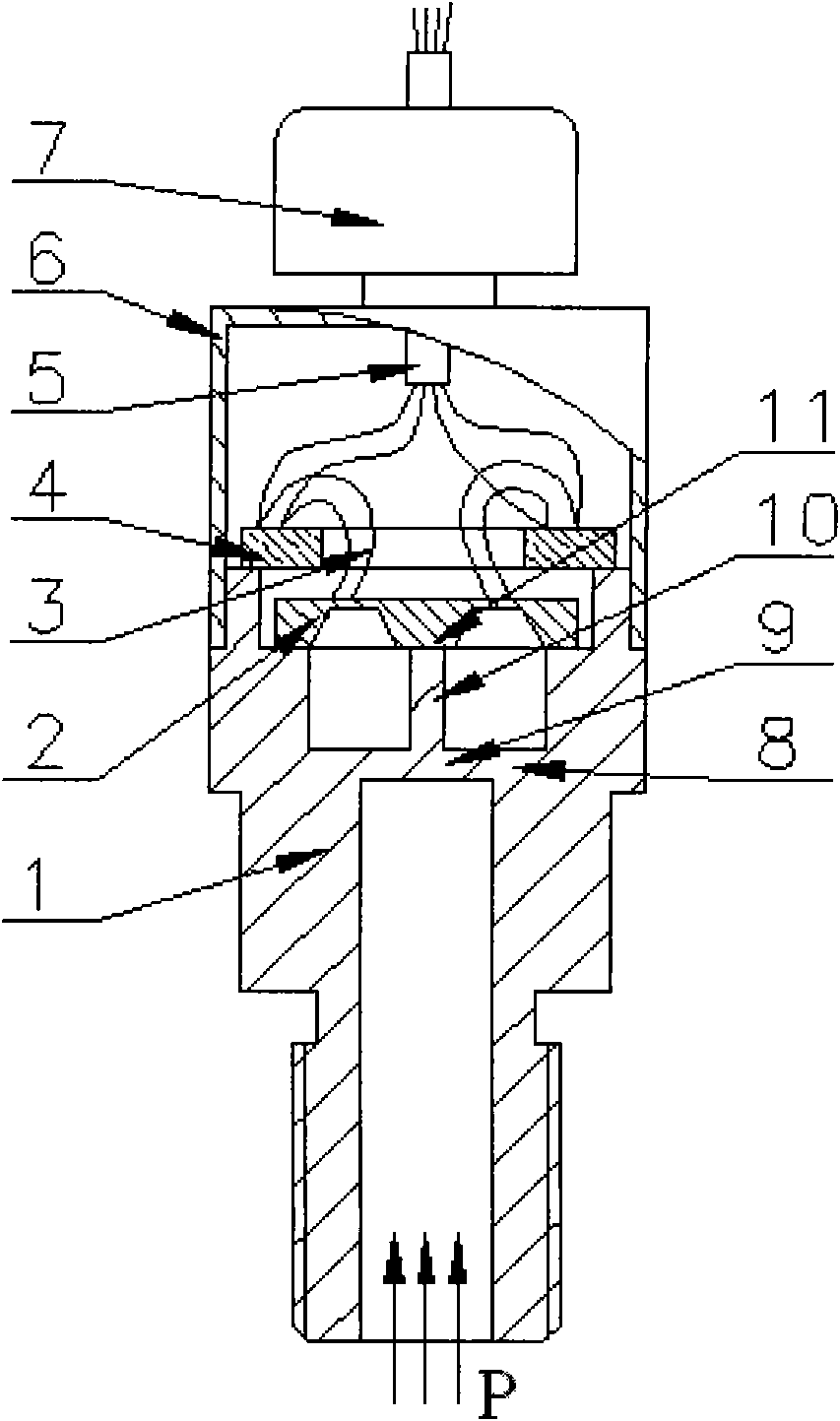

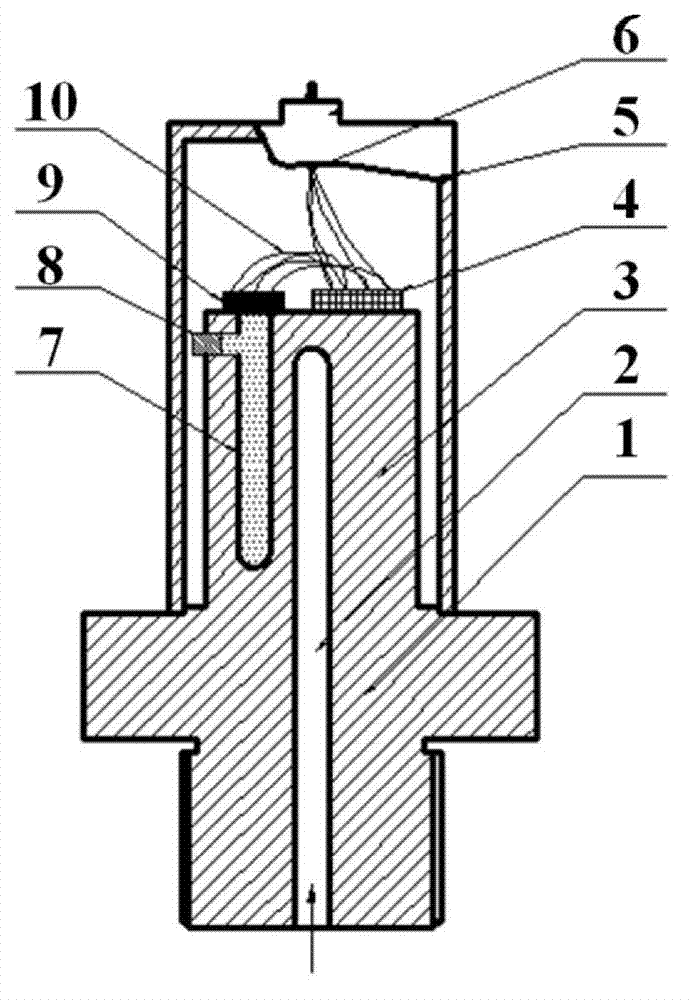

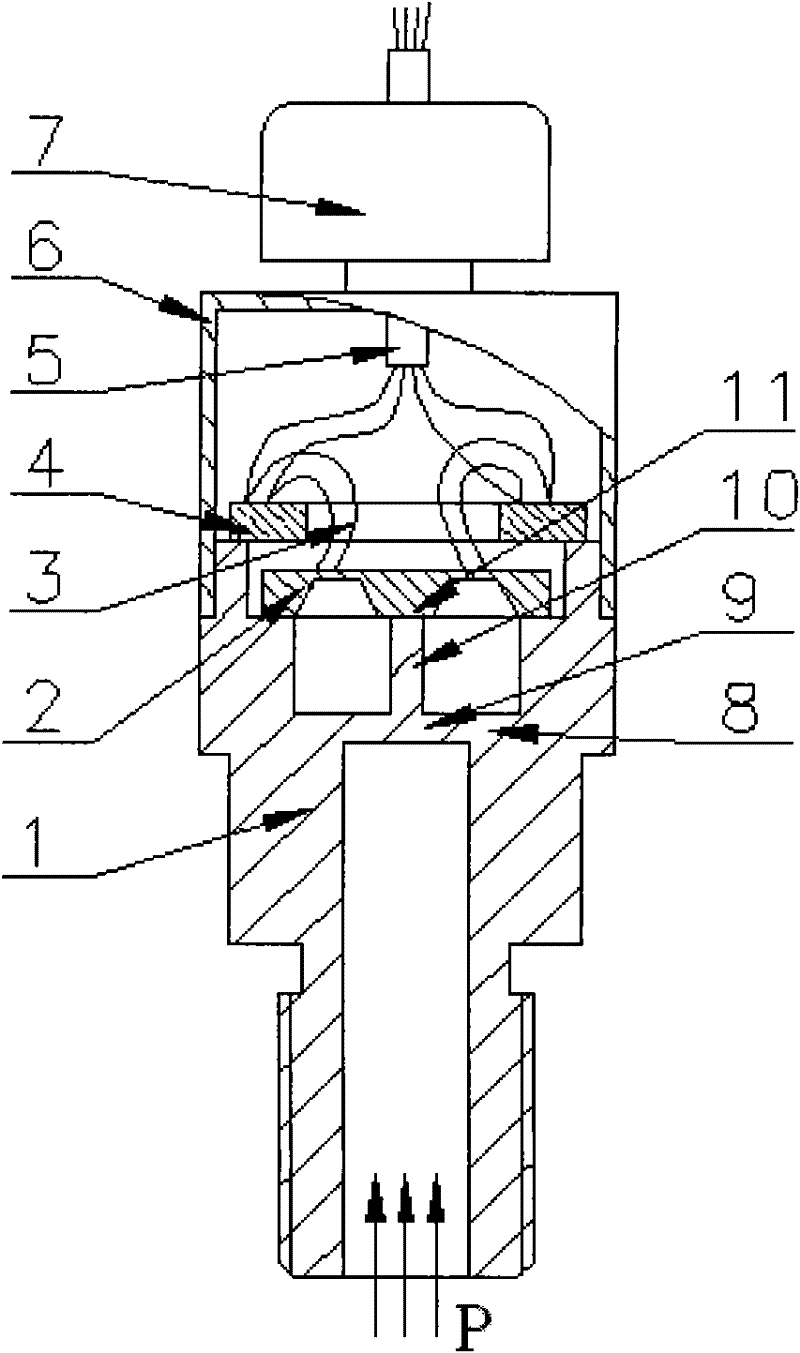

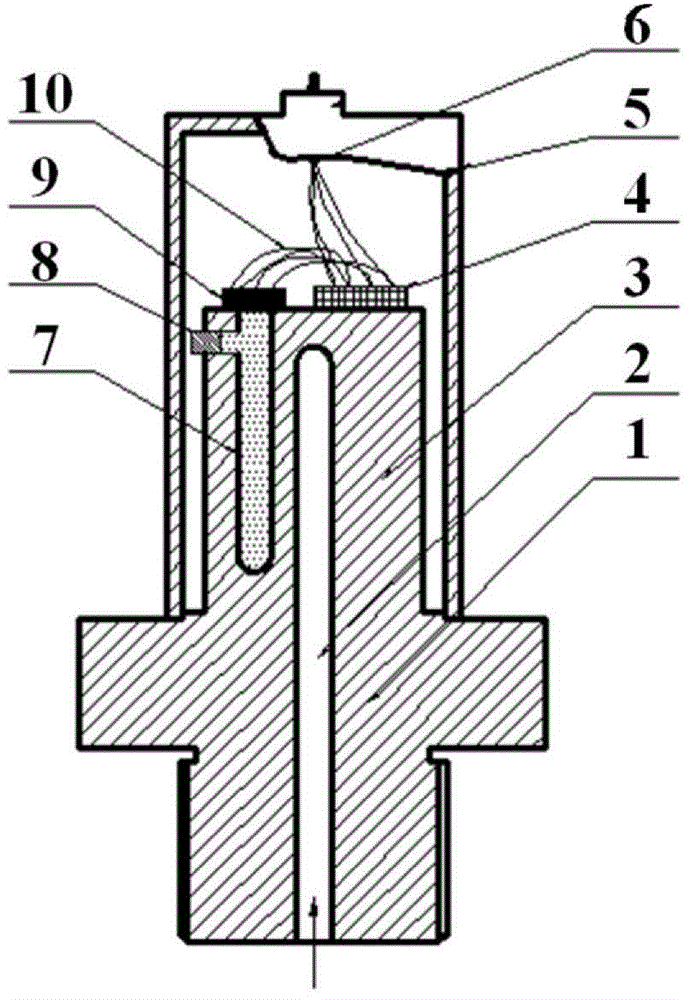

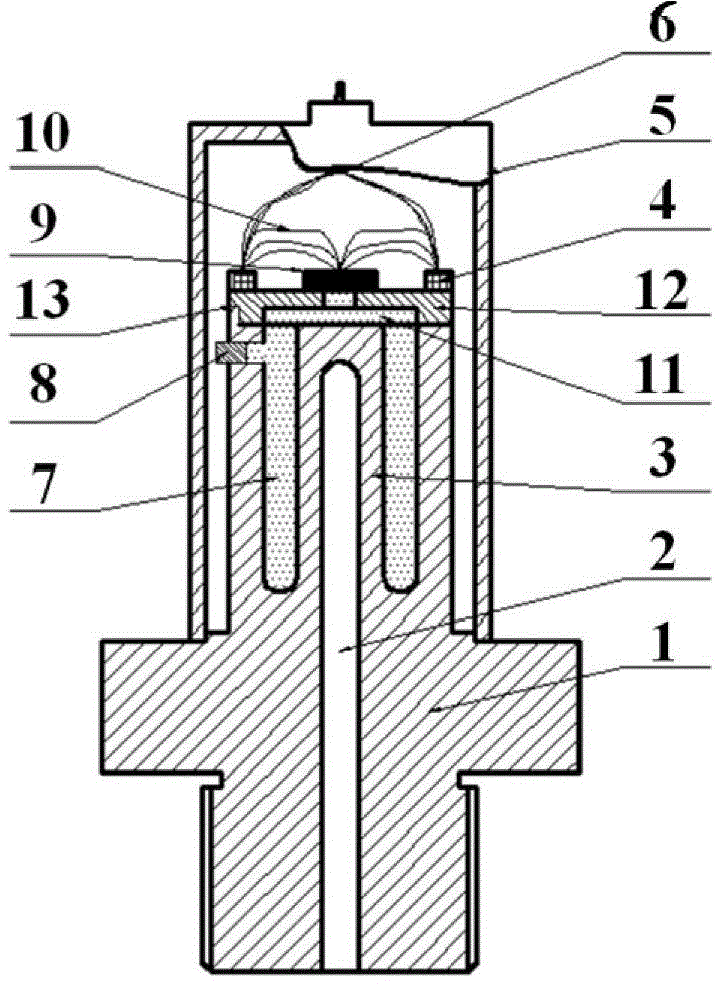

The invention discloses a composite micro-electro-mechanical system (MEMS) high-temperature resistant ultrahigh-pressure sensor. The sensor comprises a base, a silicon beam sensitive element, a high-temperature adapter plate and a shell, wherein the shell is assembled on the base; the silicon beam sensitive element is connected to a high-temperature cable through a gold wire lead and the high-temperature adapter plate and is connected with an external circuit; the base is combined with a foundation support through a pressure-bearing elastic element; the middle of the pressure-bearing elastic element is provided with a circular membrane which is provided with a dowel bar; the silicon beam sensitive element has an E-shaped cup structure of which the middle is provided with a measuring island; the silicon beam sensitive element is assembled on the pressure-bearing elastic element; the measuring island is contacted with the dowel bar; pressure is applied to the circular membrane so as to deform the circular membrane; deflection is applied to the measuring island; and constant current or voltage is processed by the silicon beam sensitive element, and an electric signal which is proportional to a tested pressure is output and transmitted to the external circuit through the gold wire lead, the high-temperature adapter plate and the high-temperature cable so as to realize measurement of the tested pressure. The sensor has the advantages of large measuring range, wide application range, high sensitivity, high signal to noise ratio and the like.

Owner:XI AN JIAOTONG UNIV

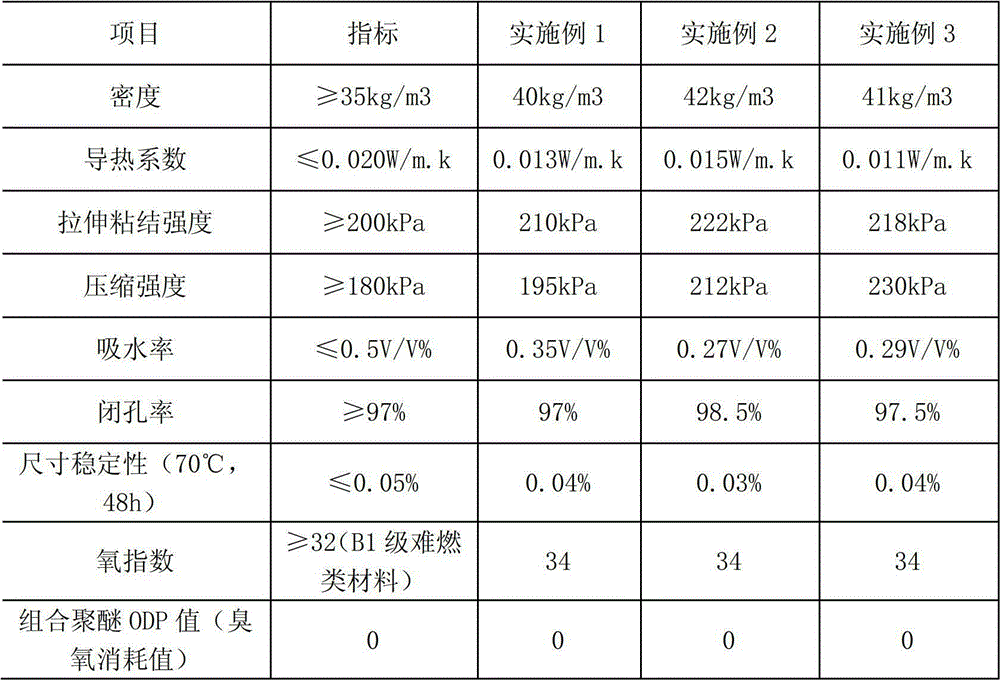

Polyurethane spray-coating composite material for storage tank thermal insulation and preparation method thereof

ActiveCN102936326AHigh compressive strengthImprove performancePolyurea/polyurethane coatingsPolyesterFoaming agent

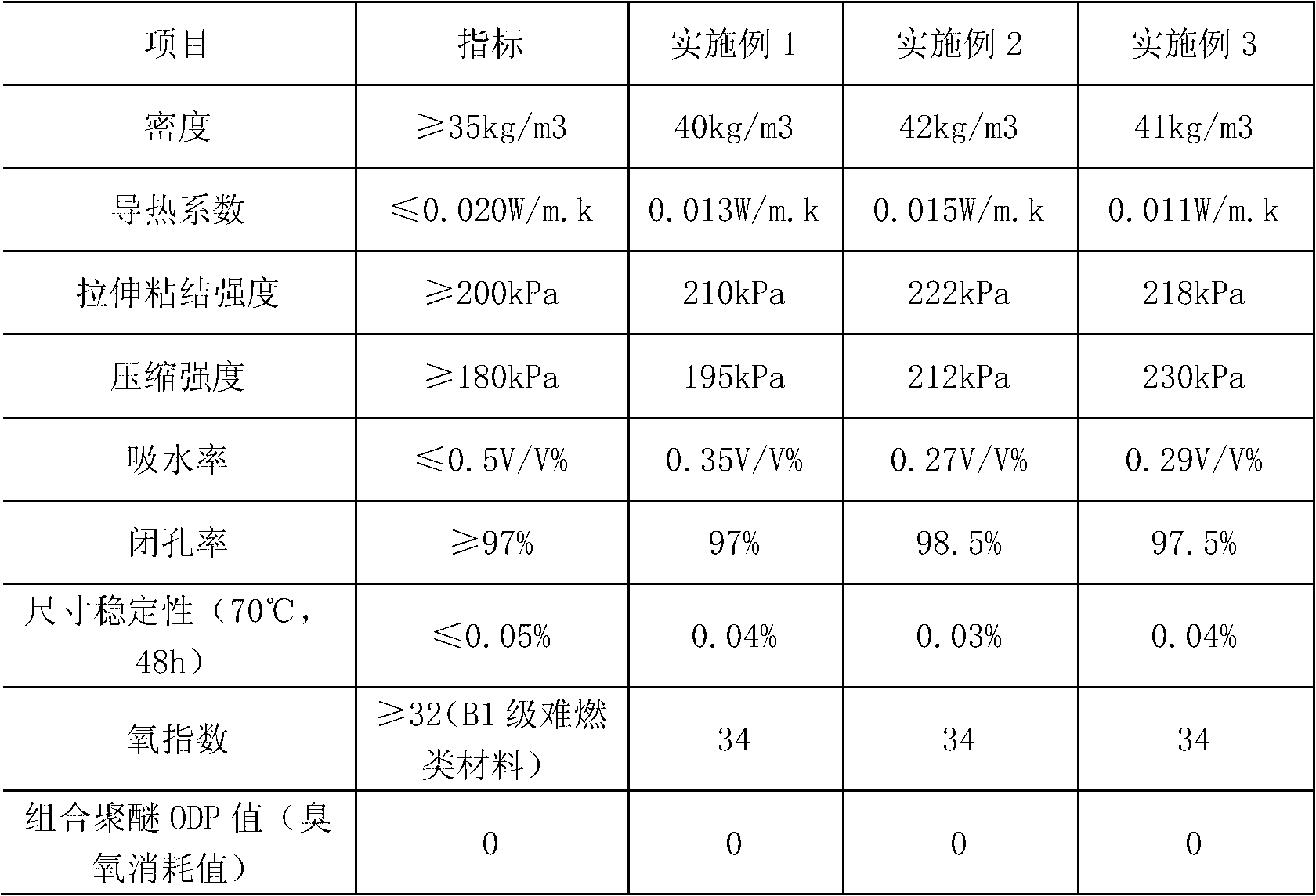

The invention relates to a polyurethane spray-coating composite material for storage tank thermal insulation and a preparation method thereof. The composite material is composed of a component A and a component B in a weight ratio of 1:(1-1.05), wherein the component A is composed of polyether glycol A, polyether glycol B, polyester polyol, foam stabilizer, chemical foaming agent, physical foaming agent, catalyst, flame retardant and other assistants; and the component B is polymethylene polyphenyl polyisocyanate. The preparation method comprises the following steps: sequentially adding the components in the component A into a reaction kettle, and thoroughly mixing for 0.5-1 hour at normal temperature; and evenly mixing the component A and the component B in a weight ratio of 1:(1-1.05) with a high-pressure spray coater, atomizing, foaming, and quickly forming and aging the foam to obtain the product. The foam provided by the invention has the advantages of environmental protection, low heat conductivity coefficient and high flame retardancy, and is especially suitable for thermal insulation construction of tank bodies.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

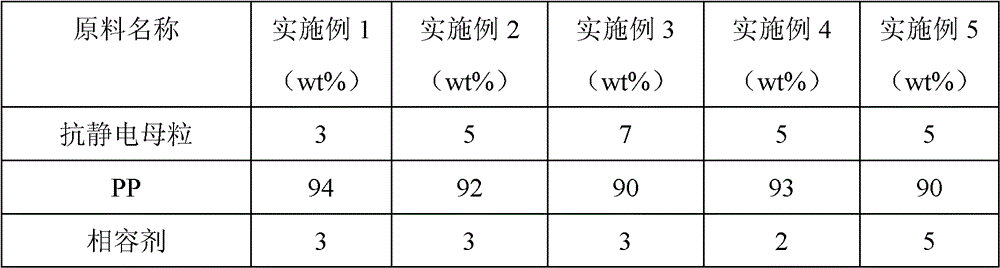

Permanent anti-static PP (polypropylene) composite material and preparation method thereof

ActiveCN102399393ALong-lasting antistatic effectGood antistatic effectOther chemical processesSurface resistivityPolypropylene

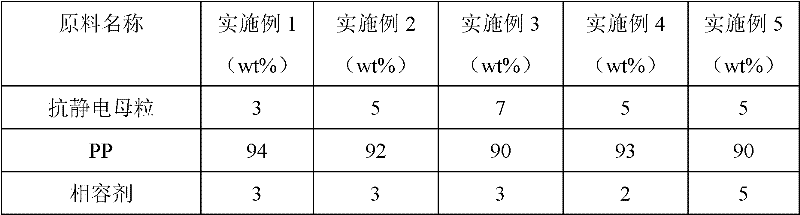

The invention relates to a permanent anti-static PP (polypropylene) composite material and a preparation method thereof. The material comprises the following components in percentage by weight: 3 to 8 percent of anti-static master batch, 80 to 95 percent of PP and 1 to 5 percent of compatilizer. The preparation method comprises the following steps of: weighing the raw materials according to weight proportion; placing the raw materials into a high mixing machine to mix the raw materials for 2 to 5 minutes; discharging; and then carrying out extrusion pelletizing by a double-screw extruder, wherein a processing temperature is in the range of 190 to 220 DEG C and screws have revolution of 35 to 40Hz. Compared with the prior art, the permanent anti-static PP composite material has the advantages of sustained anti-static effect, permanent anti-static effect, good anti-static effect, high comprehensive mechanical property, performance close to pure PP, light color, capability of being prepared into various colors, low cost, good heat resistance and the like. The surface resistivity of the permanent anti-static PP composite material can reach 106 to 108 ohm.m.

Owner:上海日之升科技有限公司

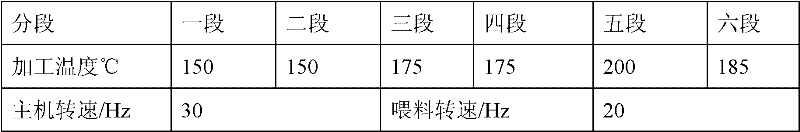

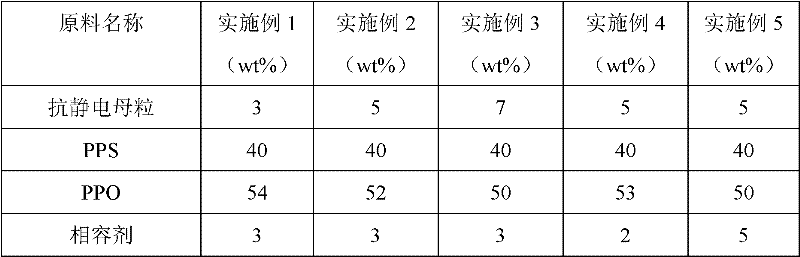

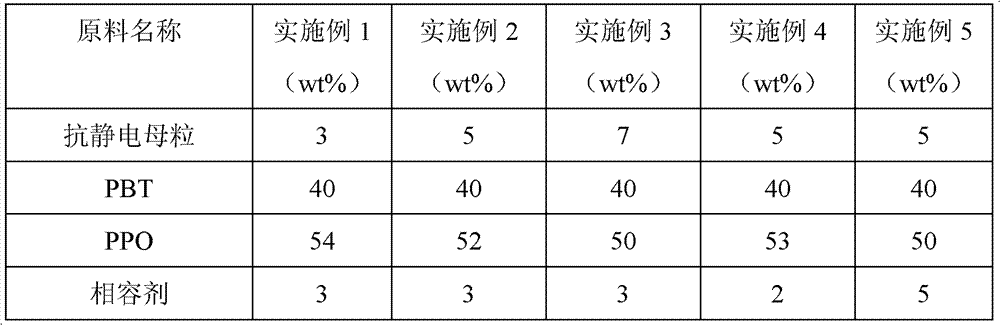

Permanent antistatic polyphenylene sulfite (PPS)/poly-p-phenylene oxide (PPO) alloy and production method thereof

InactiveCN102417730AImprove antistatic performanceImprove mechanical propertiesHeat resistanceSurface resistivity

The invention relates to a permanent antistatic polyphenylene sulfite (PPS) / poly-p-phenylene oxide (PPO) alloy and a production method thereof, wherein the material comprises the following component in percentage by weight: 3-8% of antistatic masterbatch, 40-45% of PPS, 40-50% of PPO and 1-5% of compatilizer, raw materials are placed into a high speed mixer according to the weight percentage to mix for 2-5 min, are discharged, and are extruded and granulated through a double-screw extruder, the processing temperature is between 285-325 DEG C, and the rotational frequencies of screws are 35-40Hz. Compared with the prior art, the invention has the advantages of permanent antistatic effect, realization of permanent antistatic effect, good antistatic effect and higher comprehensive mechanical property; and being approximate to the performance of the pure PPS / PPO alloy, having light color, being capable of being made up into other colors, and having low cost, good heat-resistant quality and the like. The surface resistivity of the PPS / PPO alloy can reach 106-108 omega.m.

Owner:SHANGHAI SUNNY

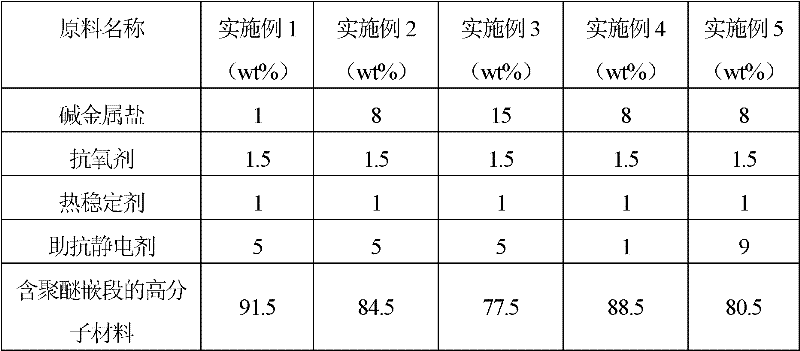

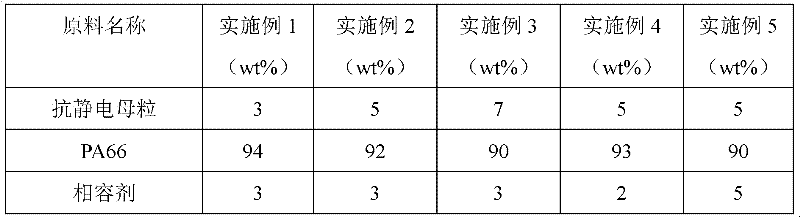

Permanent antistatic master batch, permanent antistatic PA66/PA6/PP (Polyamide 66/Polyamide 6/Polypropylene) alloy and preparation method thereof

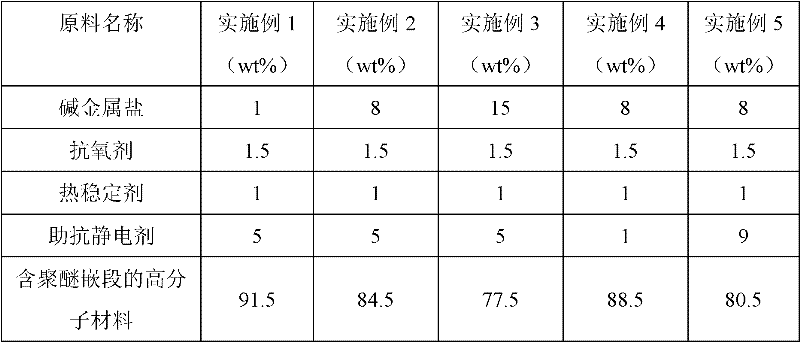

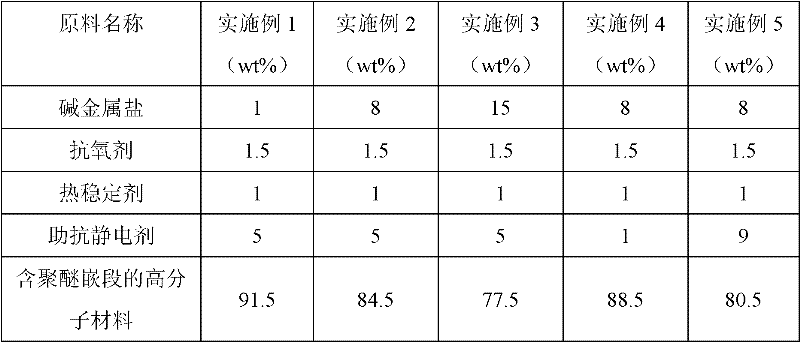

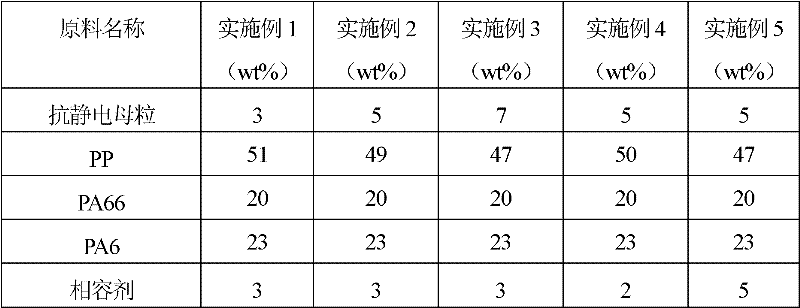

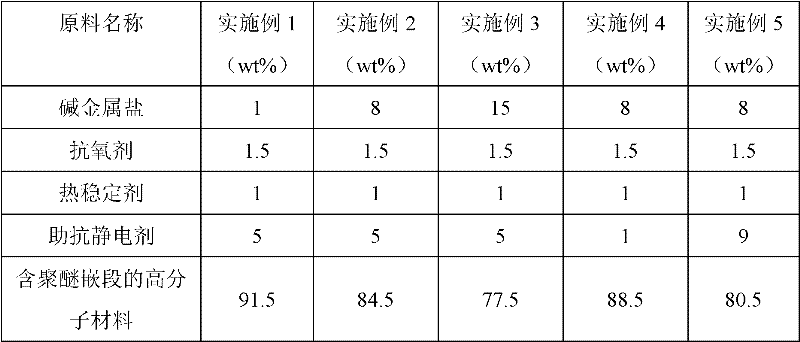

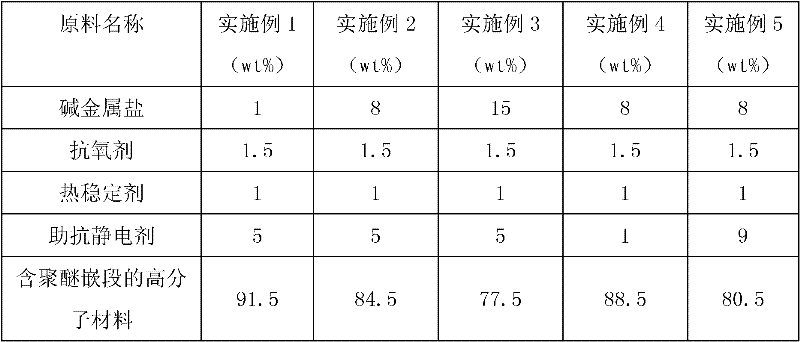

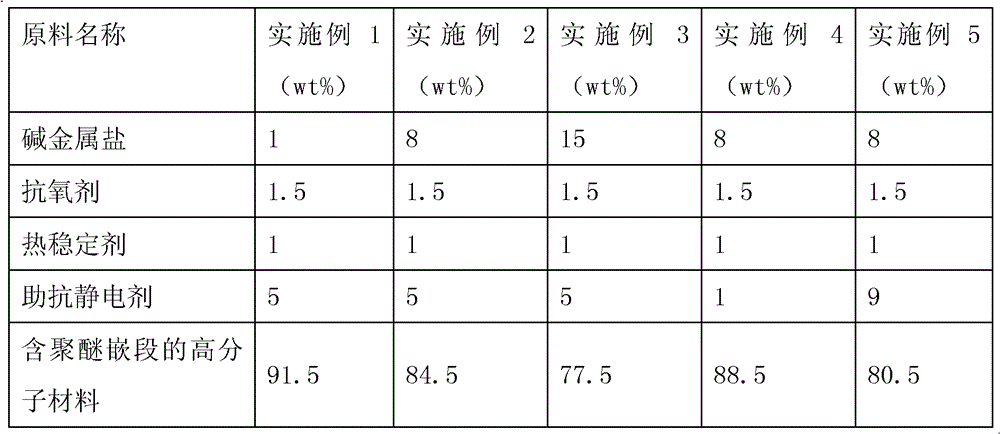

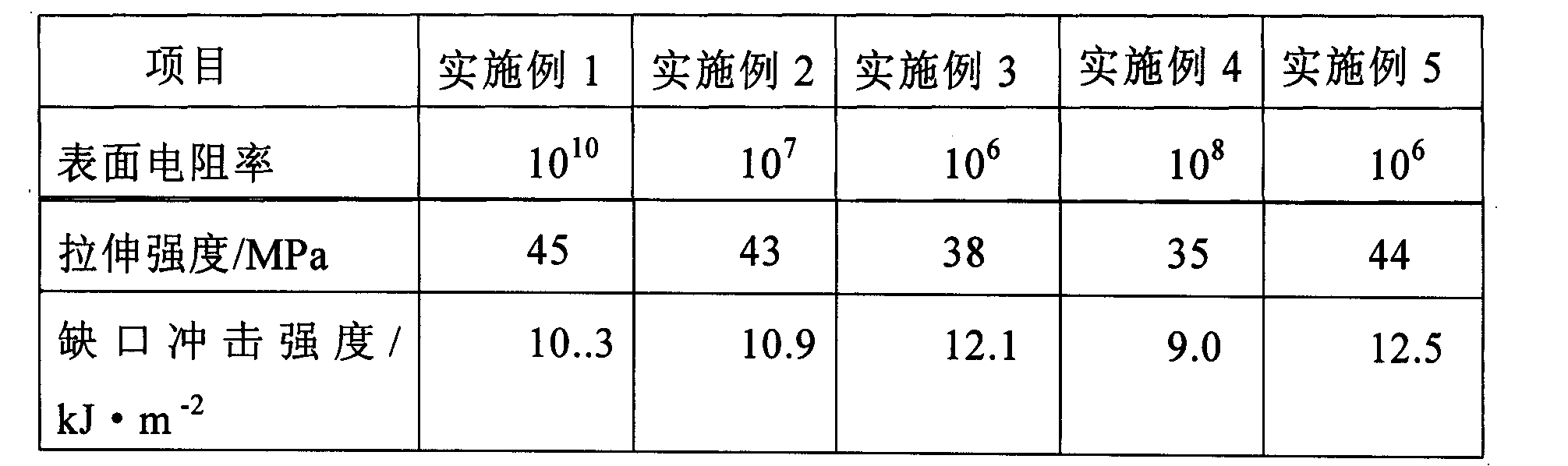

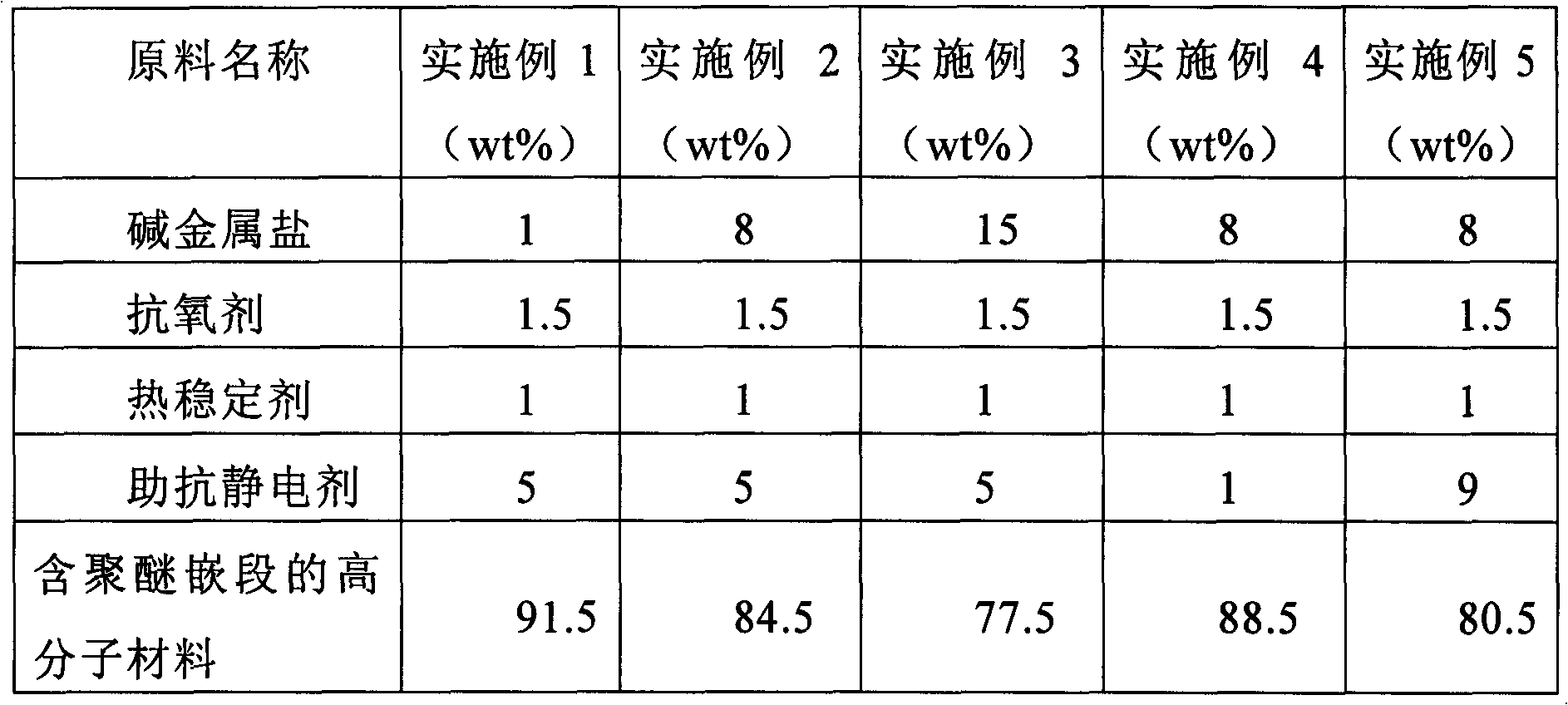

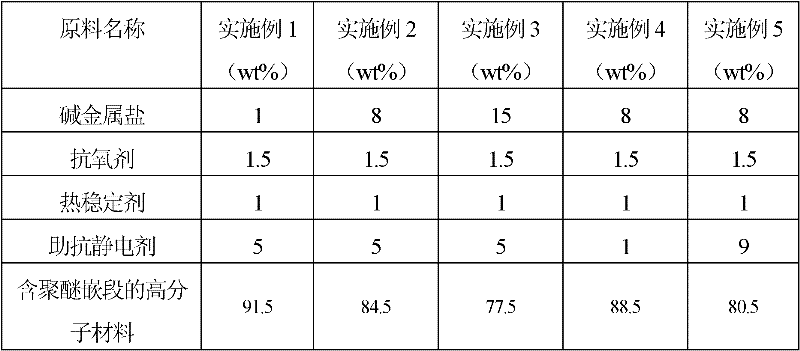

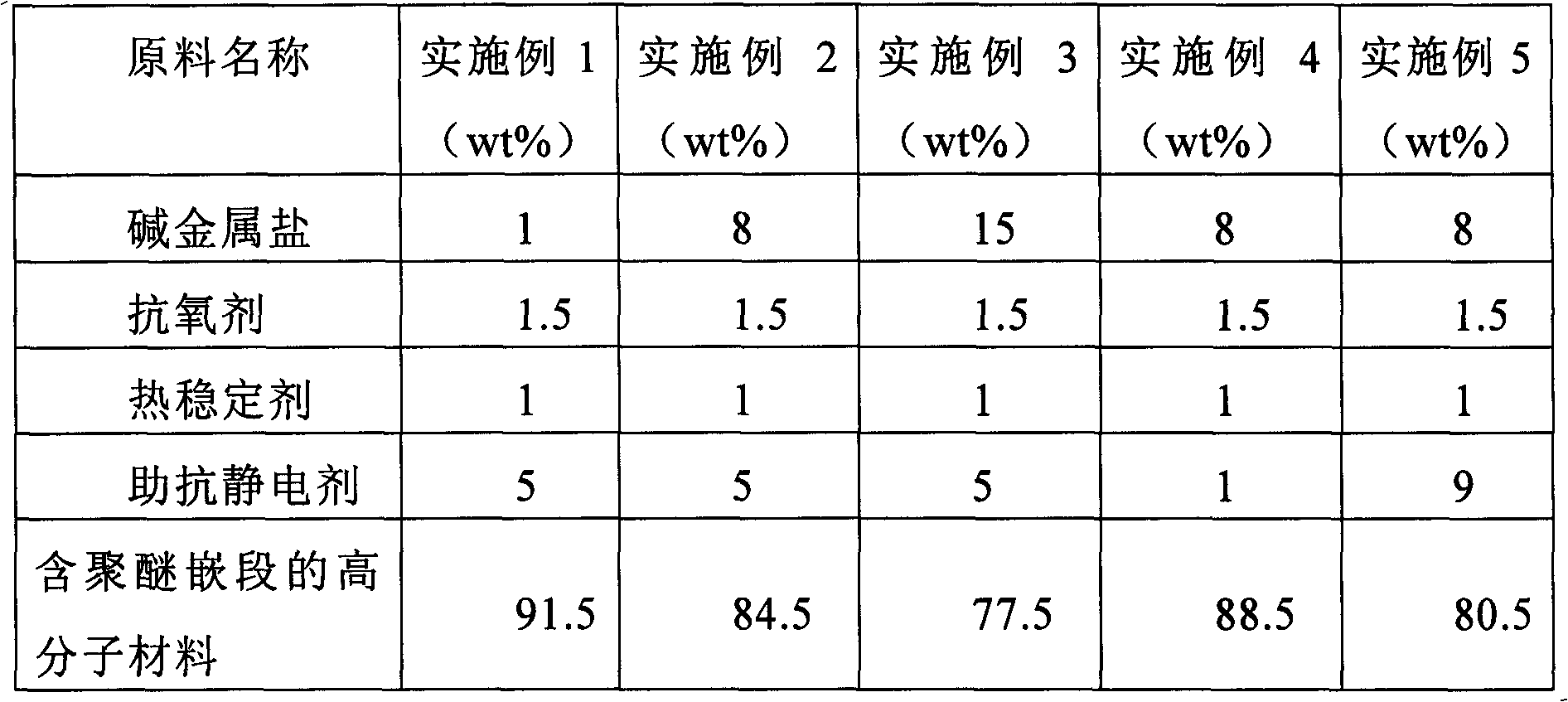

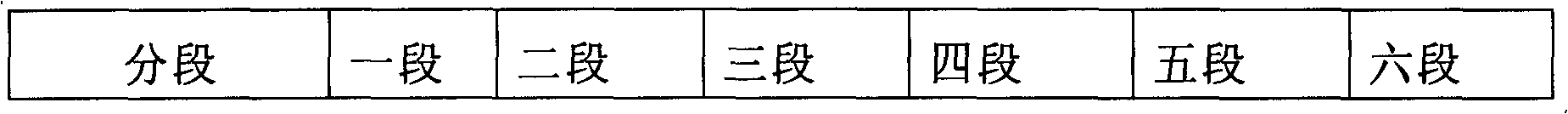

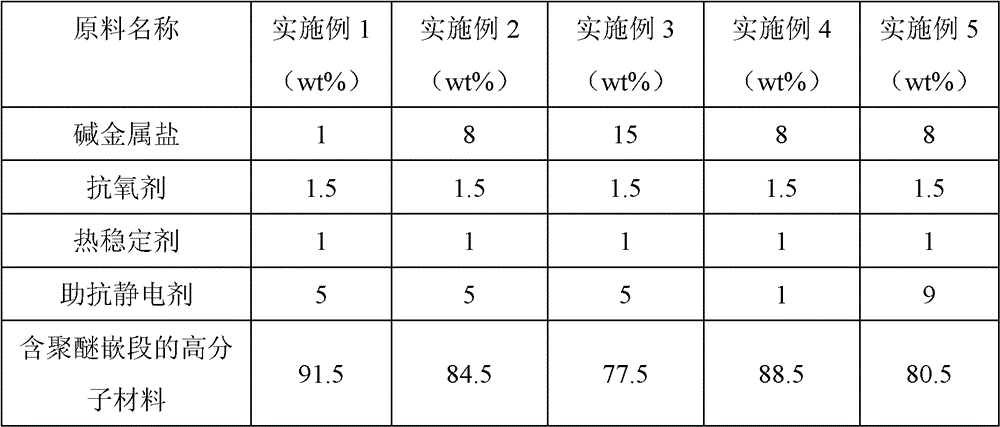

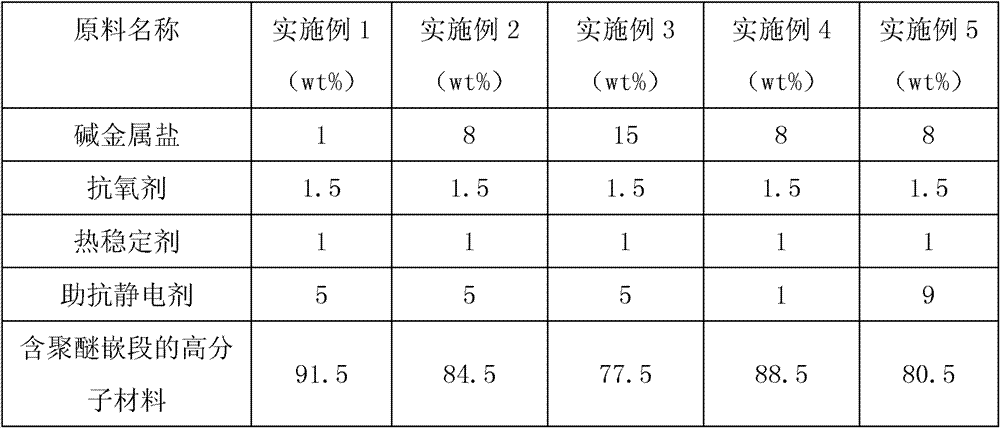

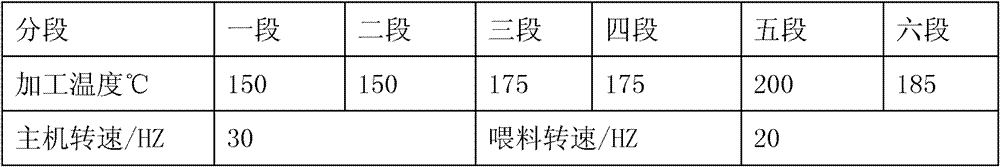

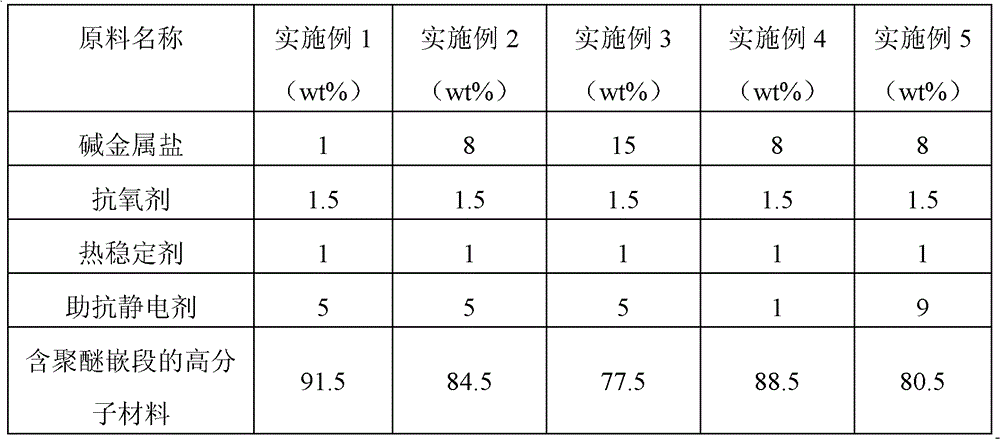

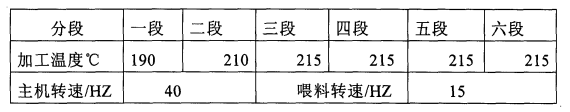

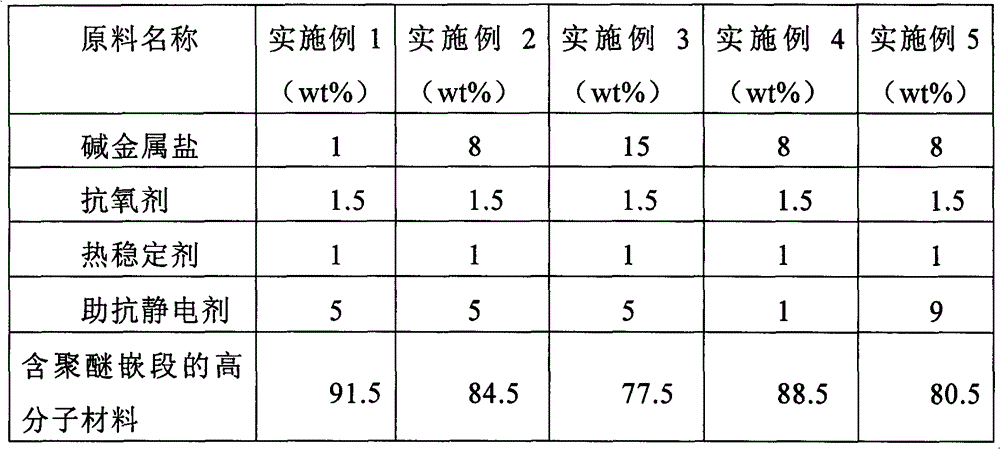

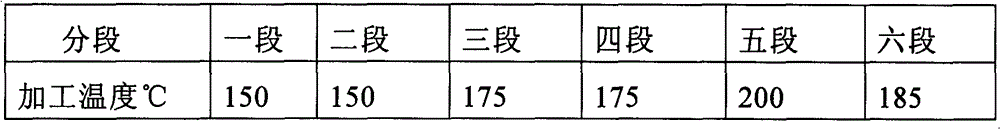

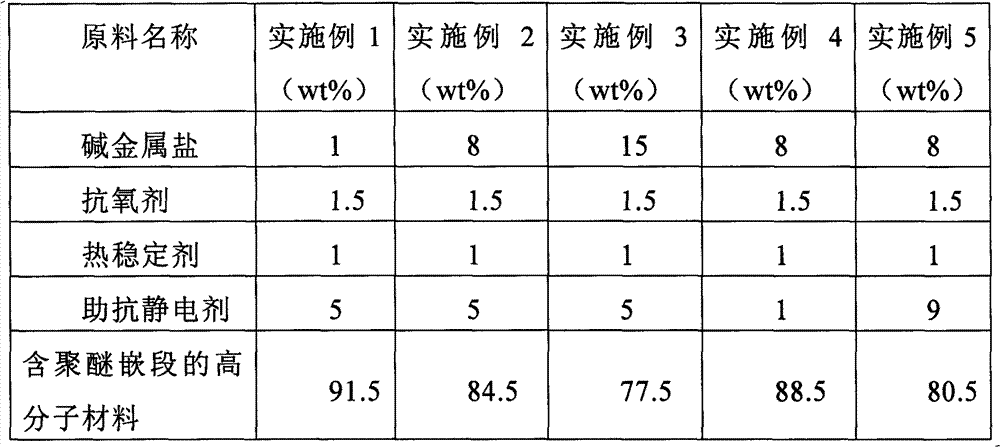

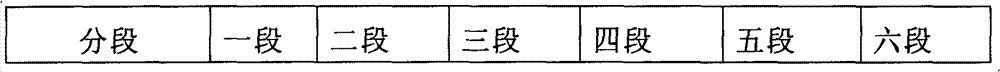

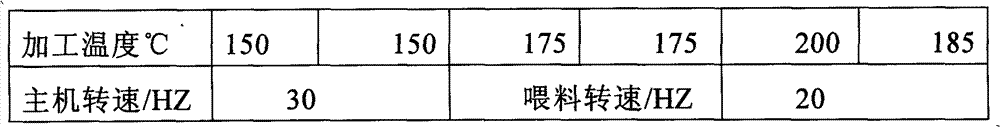

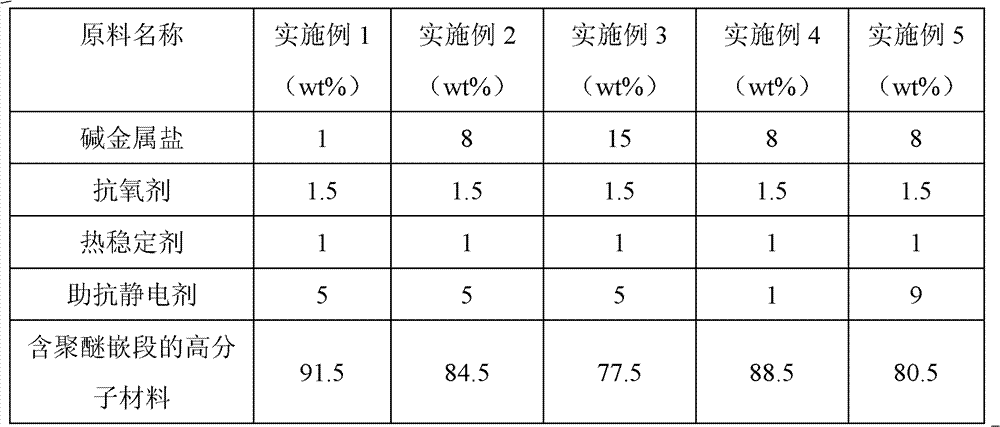

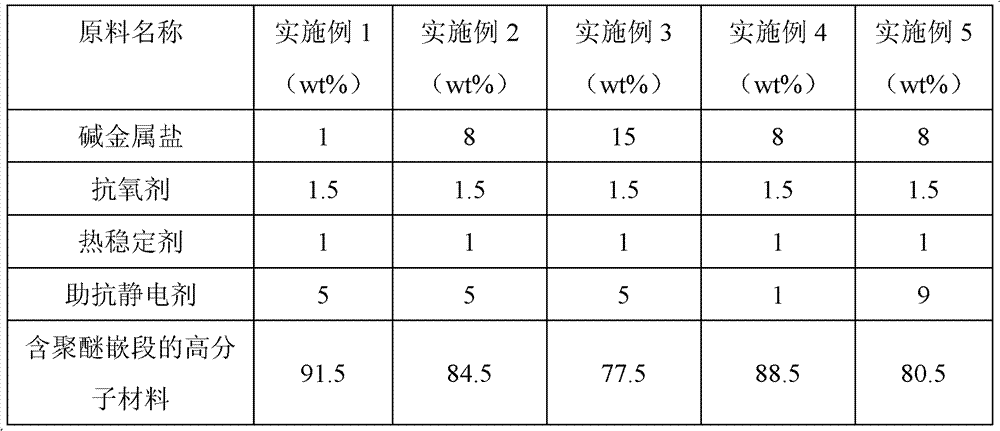

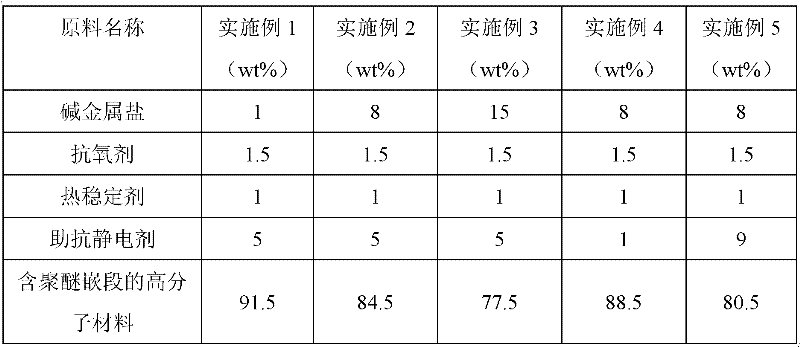

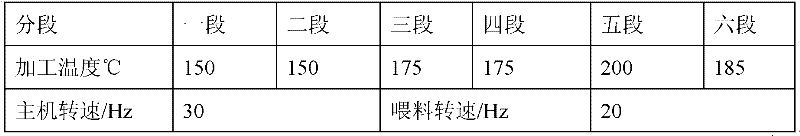

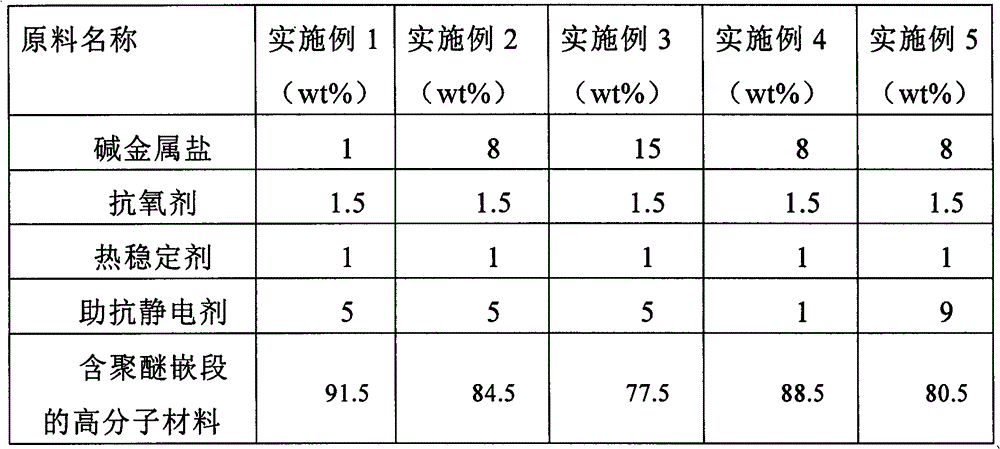

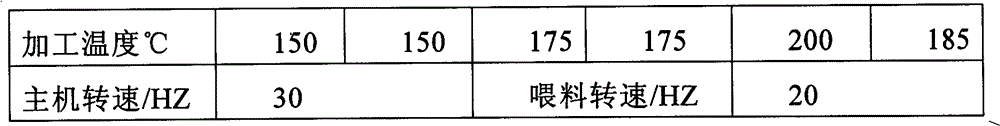

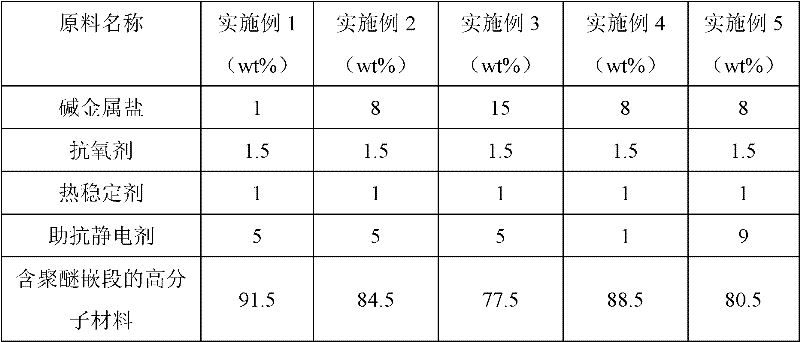

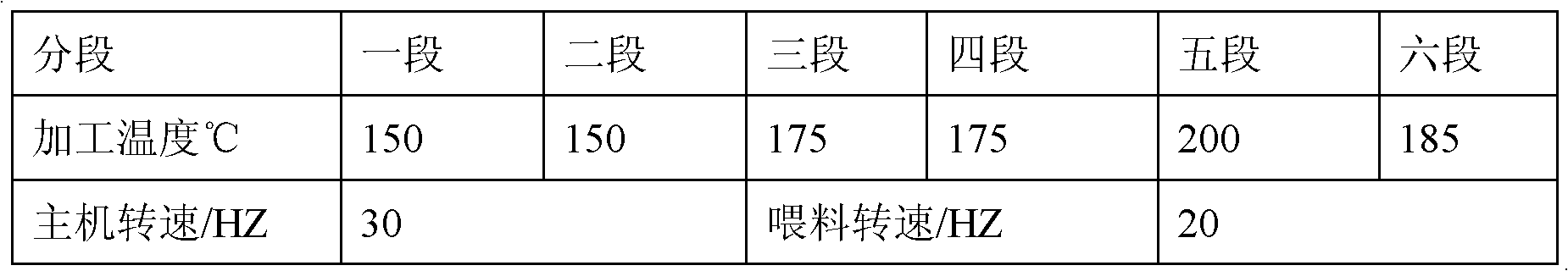

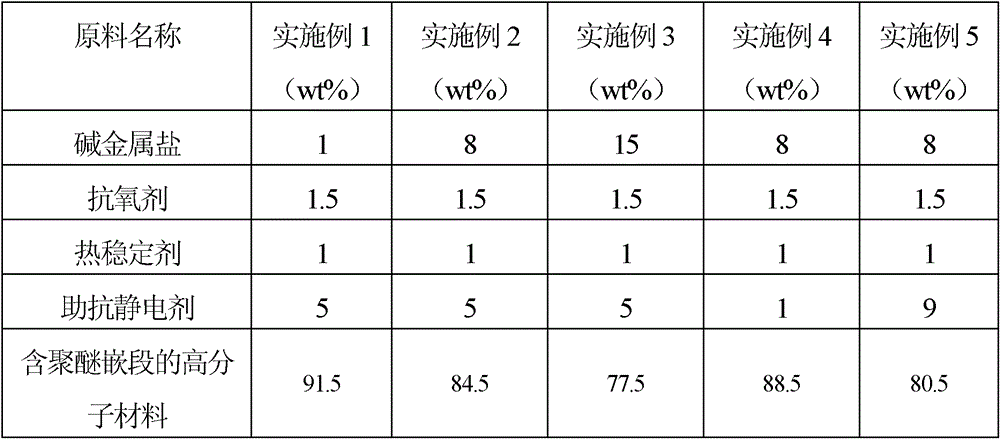

The invention provides an antistatic master batch, which comprises the following components in percentage by weight: 1-15 percent of alkali metal salt, 0.1-2 percent of antioxidant, 0.1-2 percent of heat stabilizer, 0.01-10 percent of assisting antistatic agent and 71-95 percent of polyether block-containing high polymer material. The invention further provides an antistatic alloy made of the master batch. The antistatic alloy comprises the following components in percentage by weight: 2-8 percent of antistatic master batch, 20-23 percent of PA66 (Polyamide 66), 20-23 percent of PA6 (Polyamide 6), 40-52 percent of PP (Polypropylene) and 1-5 percent of compatilizer. The invention further provides a preparation method of the master batch and the alloy. The preparation method comprises the following steps of: mixing the components for 1-10 minutes respectively, and discharging; and extruding and pelletizing. The antistatic master batch has surface resistivity of 102-103 ohm.m, a durable antistatic effect, small adding amount and high compatibility with multiple resins. The antistatic alloy has surface resistivity of 106-108 ohm.m, high comprehensive mechanical performance, low cost and high heat resistance.

Owner:上海谊盛实业股份有限公司

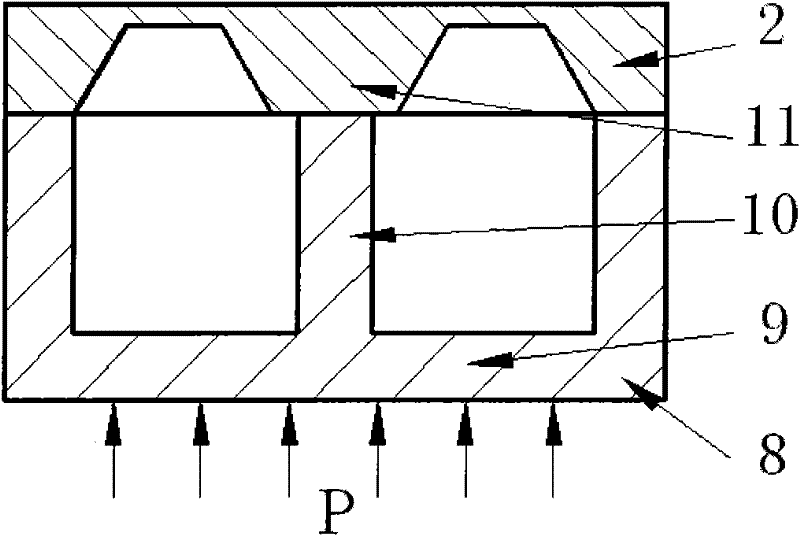

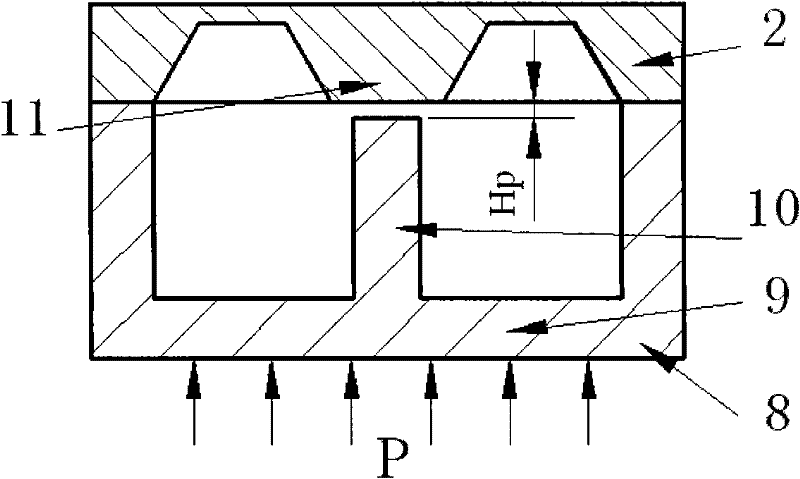

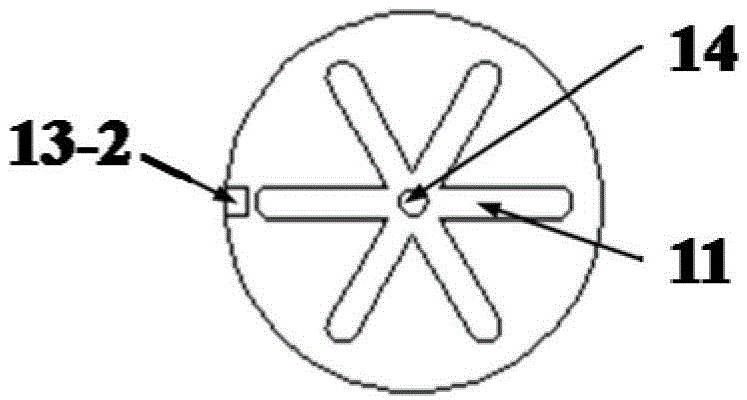

Cylinder type ultra-high-pressure sensor of side cavity oil charging structure

InactiveCN103196617AIncrease rangeOvercome the shortcoming of small measuring range of structureFluid pressure measurement using ohmic-resistance variationElectrical resistance and conductanceUltra high pressure

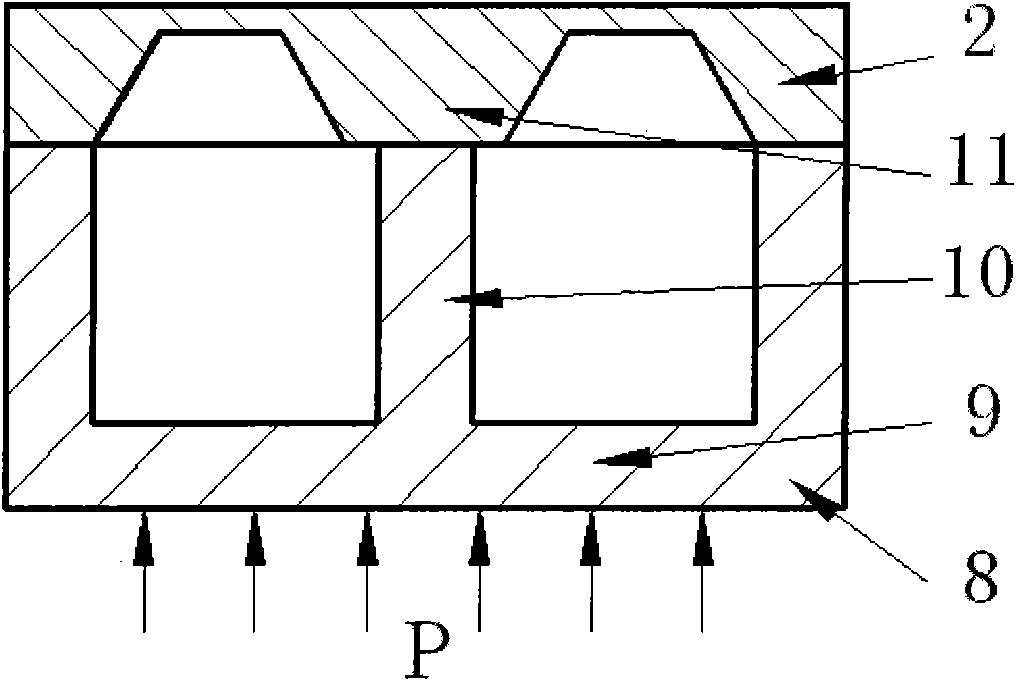

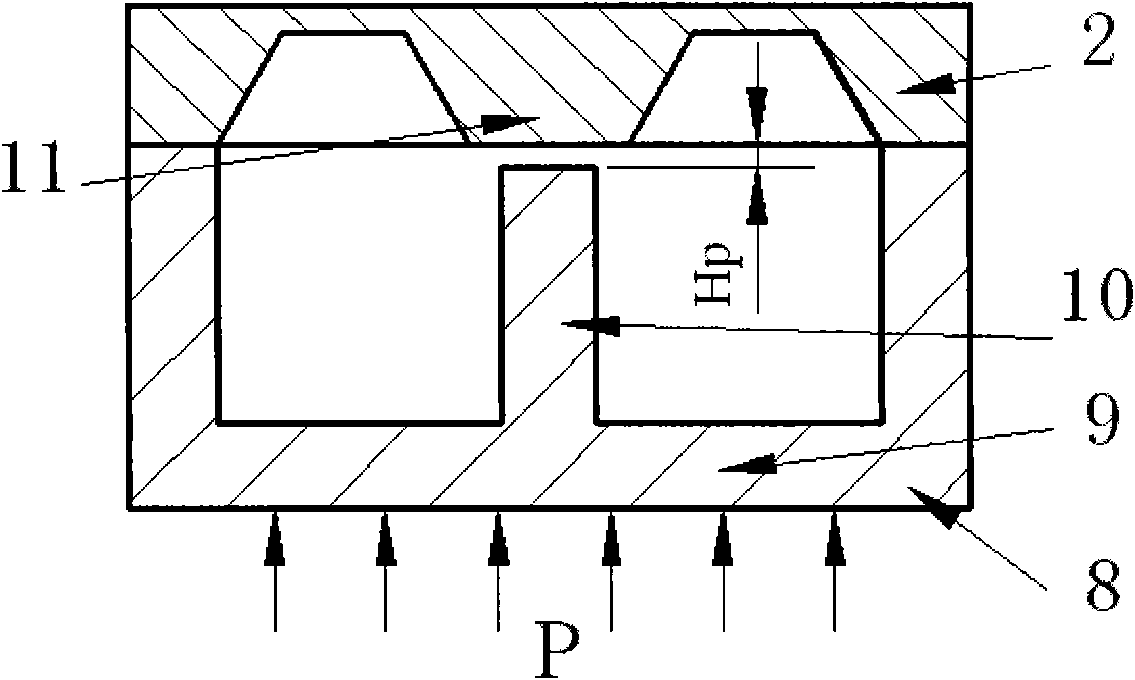

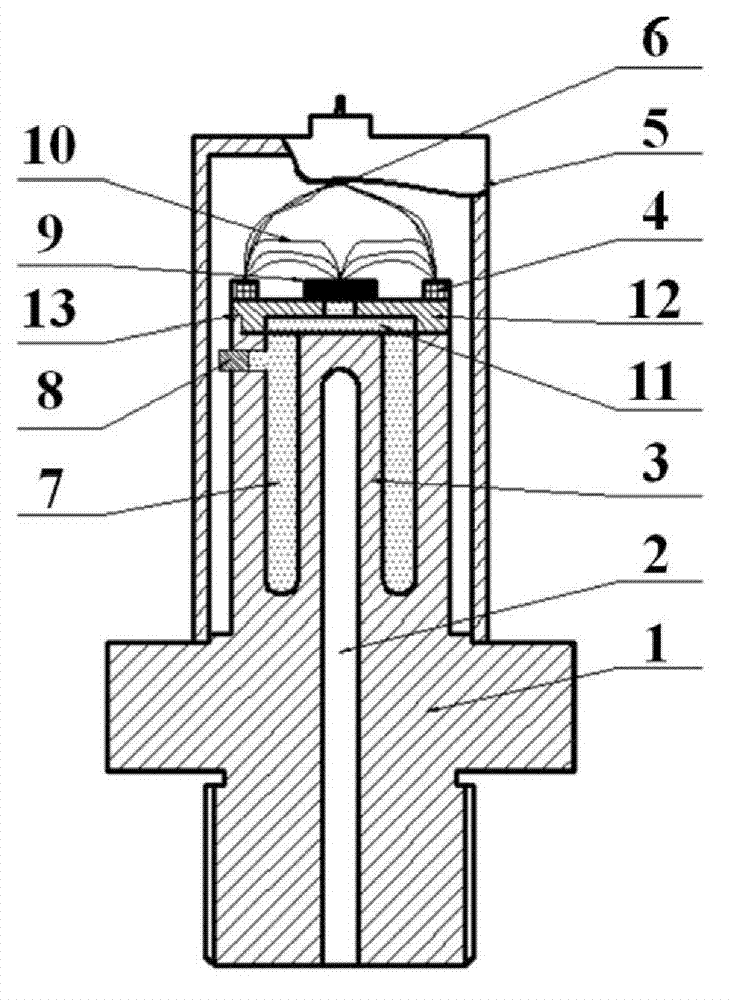

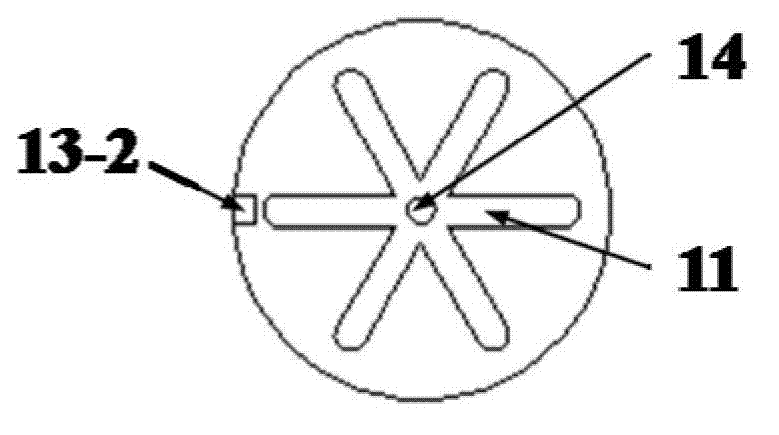

A cylinder type ultra-high-pressure sensor of a side cavity oil charging structure comprises an elastic element base, wherein the upper portion of the elastic element base is a pressure bearing cylinder, a pressure bearing hole is formed in the center of the pressure bearing cylinder, and the side wall of the pressure bearing cylinder is provided with one or more than one oil charging cavity. A Wheatstone bridge of a sensitive element is connected with a patch board through a gold wire lead, one end of a cable is connected with the output of the patch board, the other end of the cable is connected with an external circuit, incompressible silicone oil is filled in the oil charging cavity, pressure of measured media directly acts inside the pressure bearing hole, the oil charging cavity produces size deformation which is directly proportional to the measured pressure, and the deformation is transmitted to the sensitive element through the incompressible silicone oil. On the basis of the monocrystalline silicon piezoresistive effect, resistance of four voltage dependent resistors on the sensitive element changes, under drive of a stabilized power source, the four voltage dependent resistors constitute the Wheatstone bridge to output electric signals which are directly proportional to the measured pressure, and therefore detection of ultra-high-pressure can be conducted. The cylinder type ultra-high-pressure sensor can bear pressure more than 1.5 GPa.

Owner:XI AN JIAOTONG UNIV

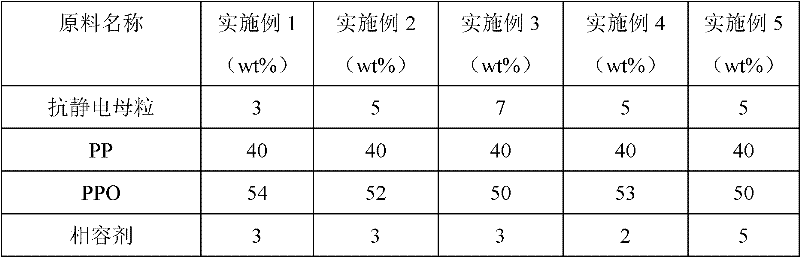

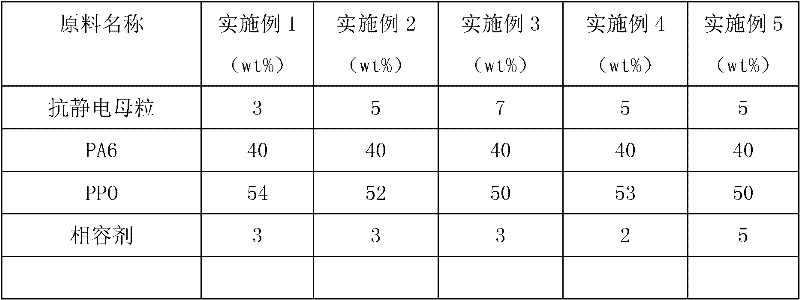

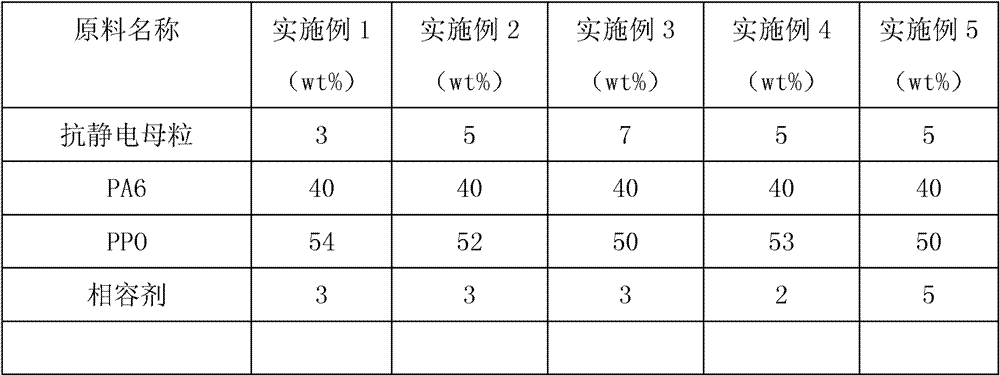

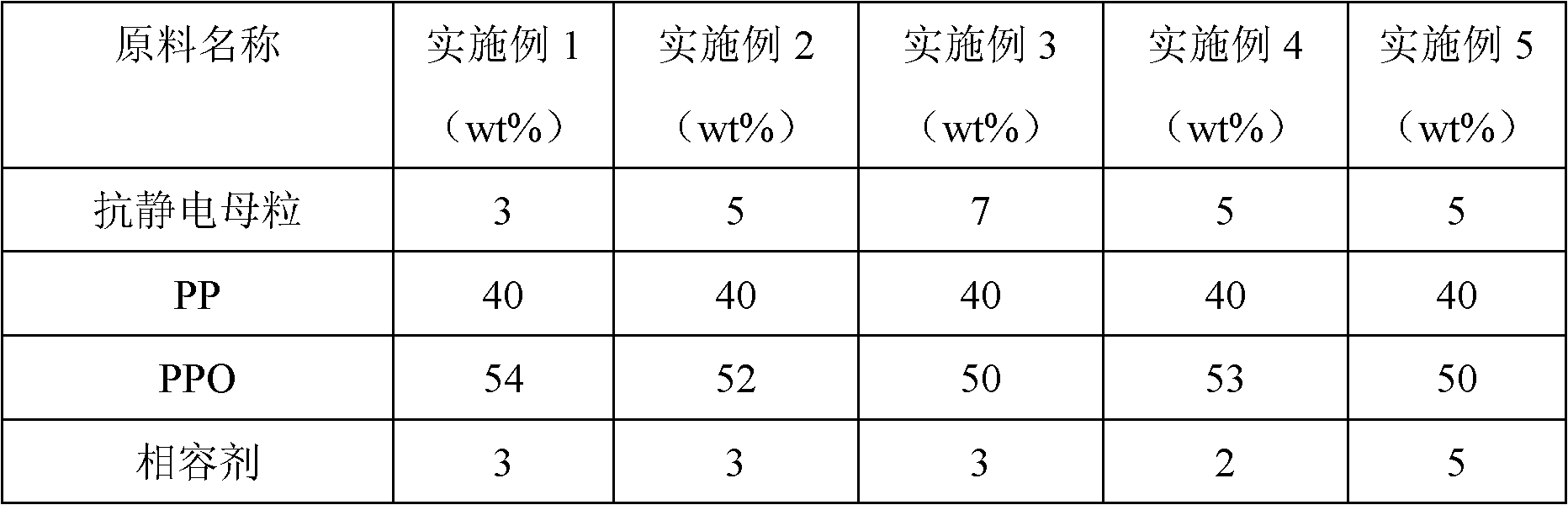

PP/PPO alloy with permanent antistatic performance and preparation method thereof

InactiveCN102417719AImprove antistatic performanceImprove mechanical propertiesHeat resistanceSurface resistivity

The invention relates to PP / PPO alloy with permanent antistatic performance and a preparation method thereof. The alloy comprises the following components by weight percent: 3 to 8% of antistatic master batches, 40 to 45% of PP, 40 to 50% of PPO and 1 to 5% of a compatilizer, and is prepared by weighing the above-mentioned raw materials by weight, putting the raw materials into a high-speed mixer for mixing for 2 to 5 min, discharging a material and carrying out extrusion and granulation on the material with a double-screw extruder, with processing temperature to be 245 to 285 DEG C and the revolution of screws to be 35 to 40 Hz. The PP / PPO alloy provided in the invention has a lasting antistatic effect, realizes a permanent antistatic effect, has the advantages of a good antistatic effect, high comprehensive mechanical properties, performance close to that of pure PP / PPO alloy, a light color capable of being blended into a variety of colors, low cost, good heat resistance, etc., and has surface resistivity up to 106 to 108 omega.m.

Owner:SHANGHAI SUNNY

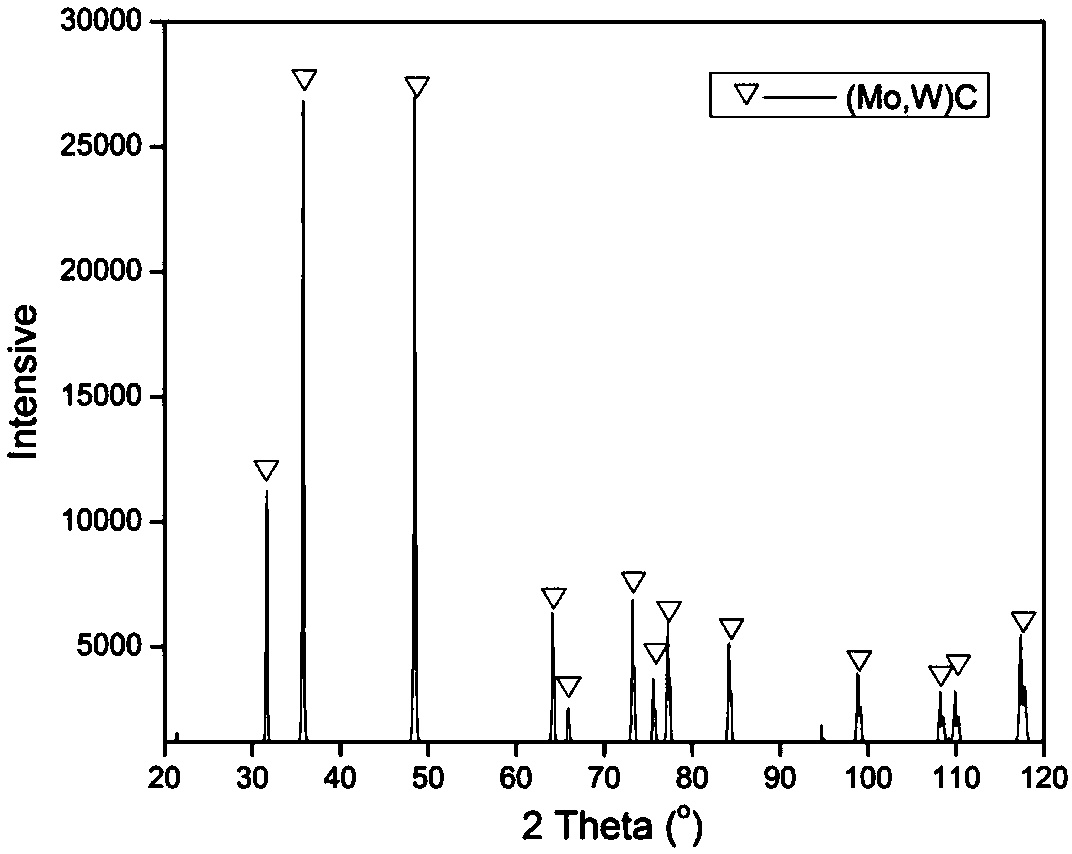

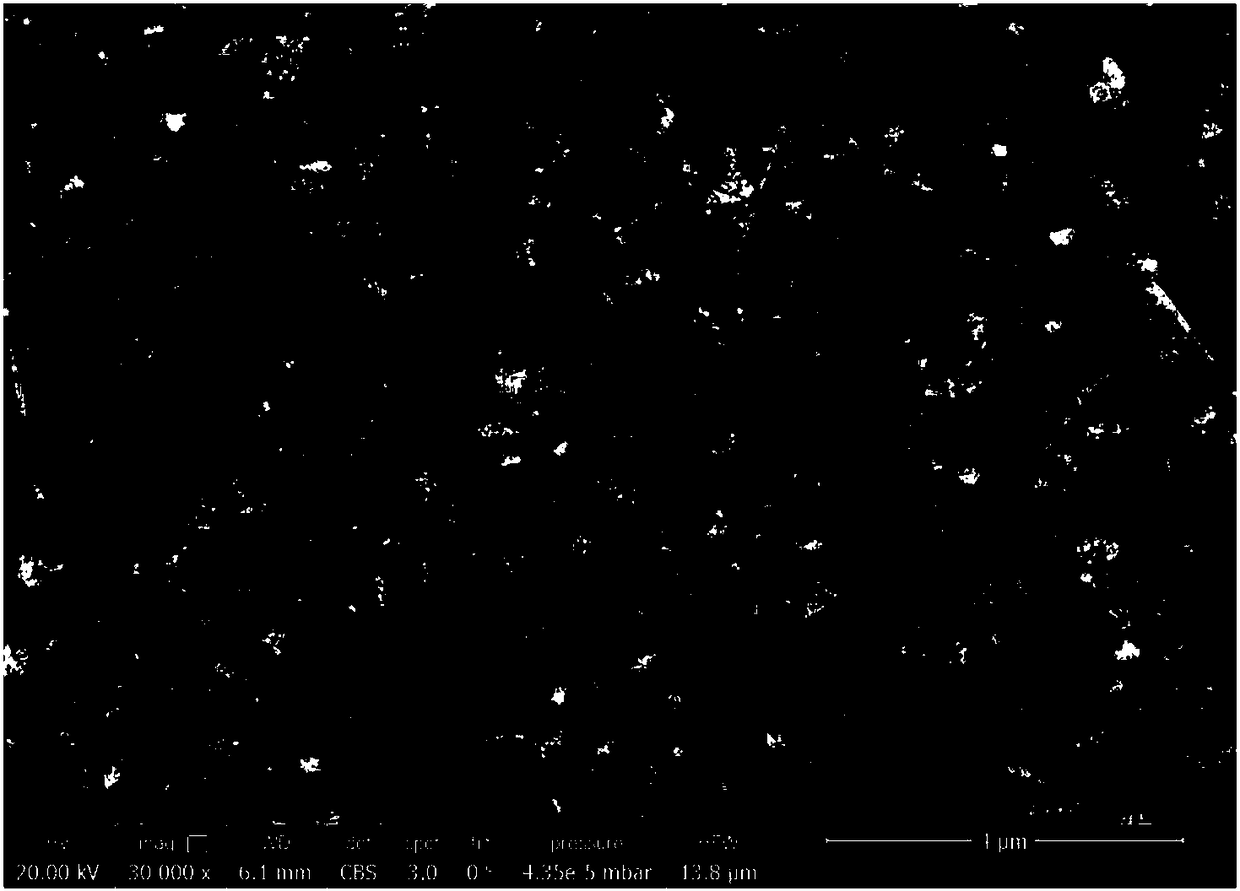

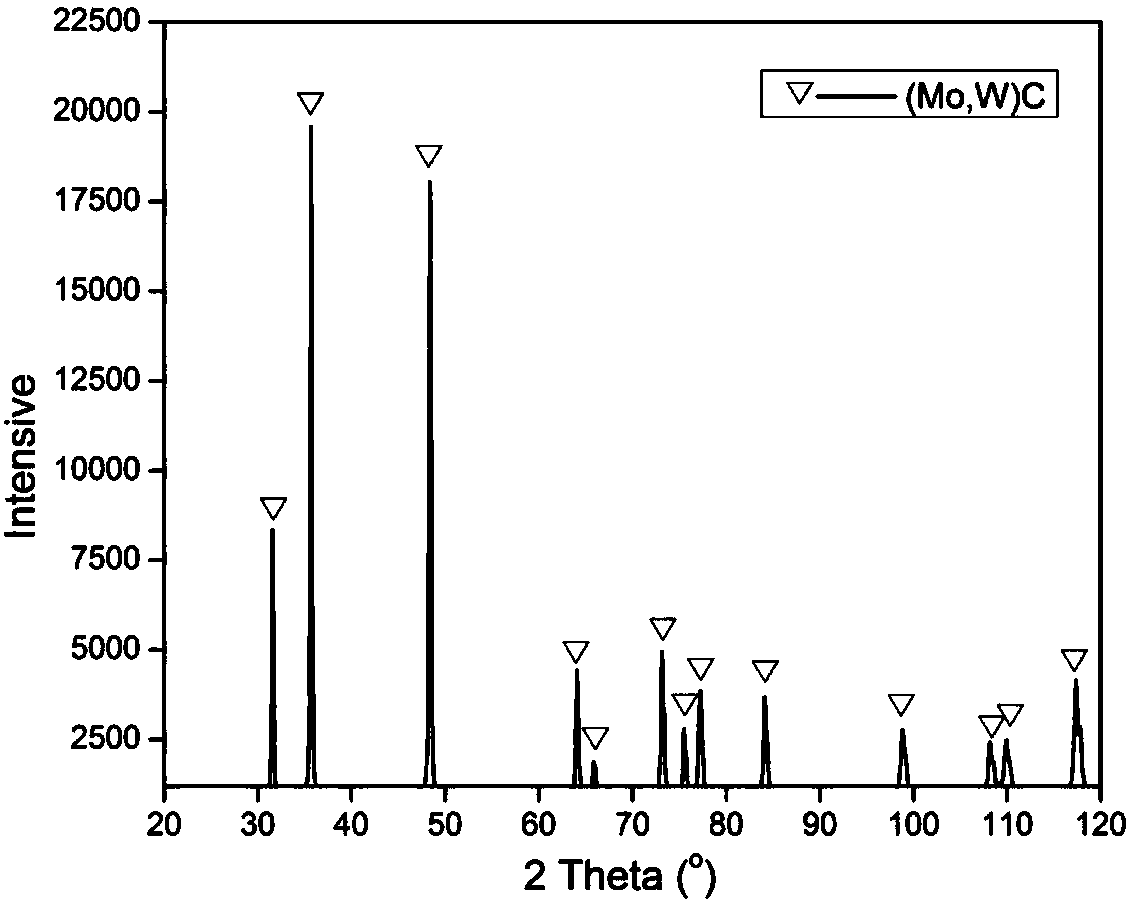

(WMo)C base hard alloy material and preparing method thereof

The invention belongs to the technical field of hard alloy preparing, and particularly relates to a (WMo)C base hard alloy material. The (WMo)C base hard alloy material comprises following componentsincluding, by mass percent, 74%-87.7% of WO3 powder, 5.1%-14.8% of MoO3 powder and 7.1%-11.2% of C powder. A preparing method of the (WMo)C base hard alloy material comprises the steps that the WO3 powder and the MoO3 powder are added in a reducing furnace to be subjected to reducing treatment, the C powder and powder obtained after reducing are mixed to be subjected to carbonization treatment, finally, the powder obtained after carbonization is stirred, and then the (WMo)C base hard alloy material is obtained. According to the (WMo)C base hard alloy material and the preparing method thereof,Mo partially replaces W for preparing of the hard alloy, and a development direction is provided for the replacement application of the non-renewable tungsten resource; meanwhile, the method is adopted for preparing the (WMo)C base hard alloy, the defects existing in a traditional Mo containing hard alloy preparing method are overcome, the Mo element in the base hard alloy prepared through the method is evenly scattered, and the function of solid dissolving of Mo in the bonding phase is improved.

Owner:ZIGONG CEMENTED CARBIDE CORP

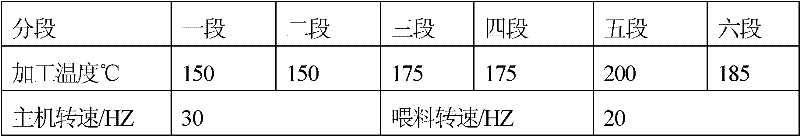

Permanent antistatic PA6/PPO (Polyamide 6/Polyphenylene Oxide) alloy and preparation method thereof

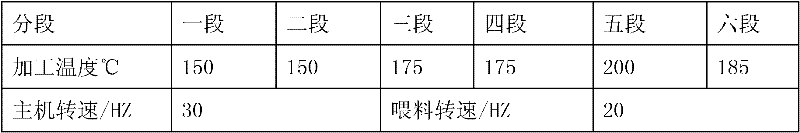

InactiveCN102417711AImprove antistatic performanceLittle impact on performancePolyethylene glycolPolyamide

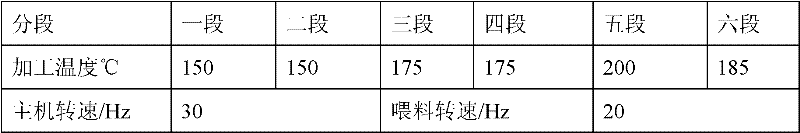

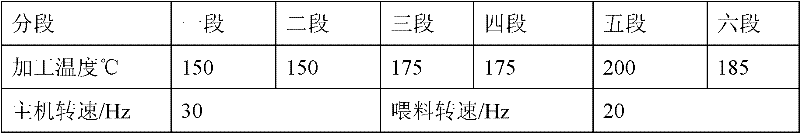

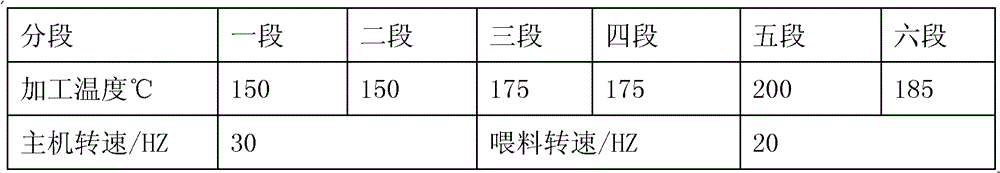

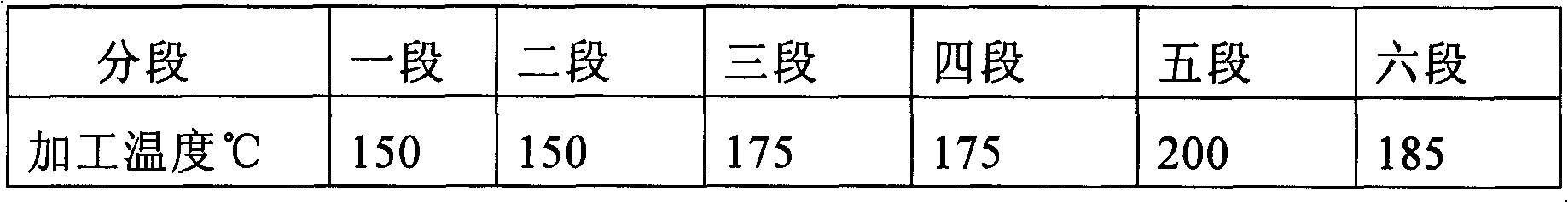

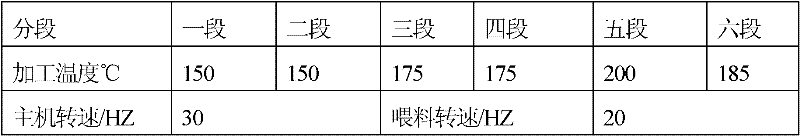

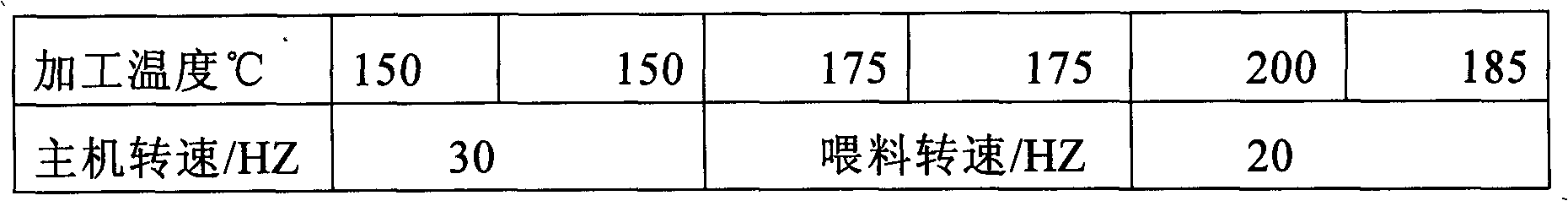

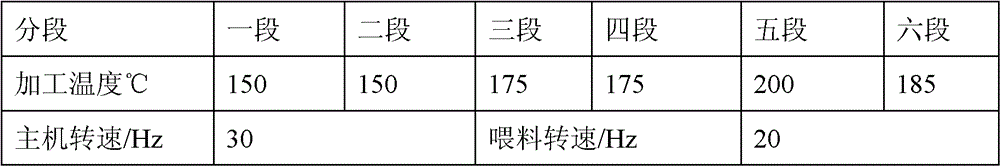

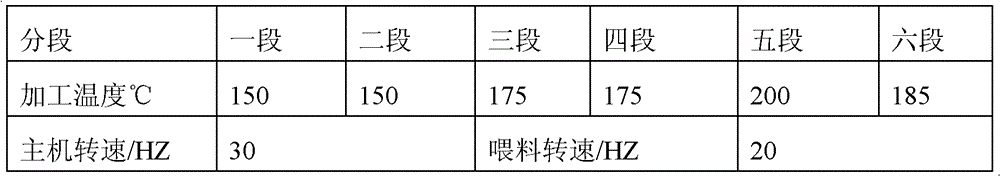

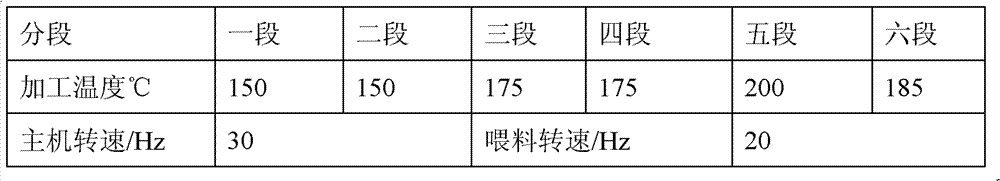

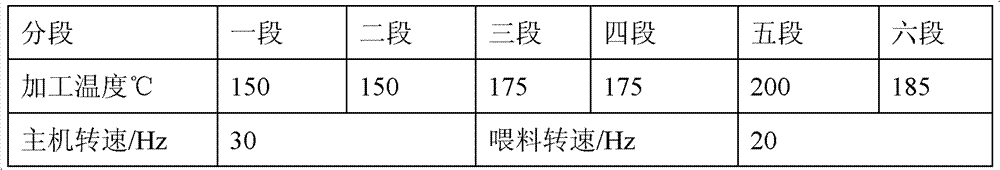

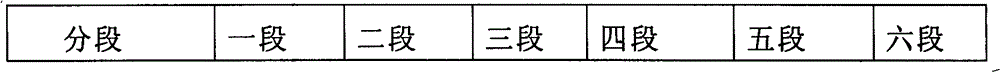

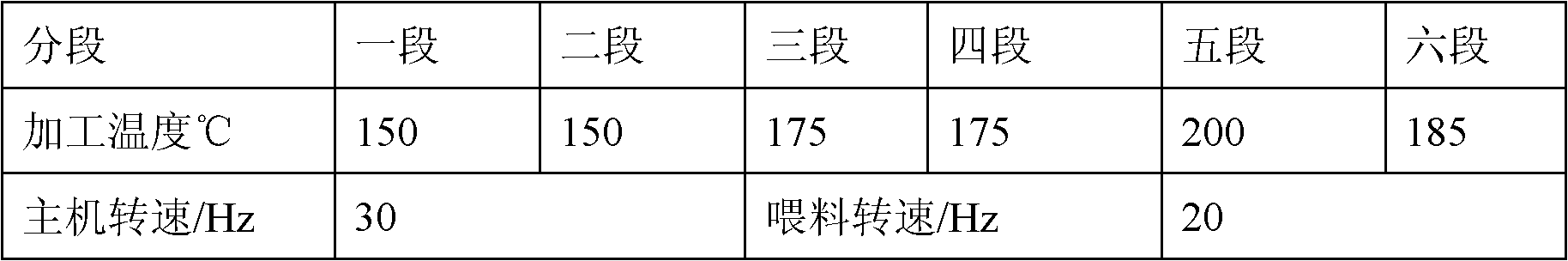

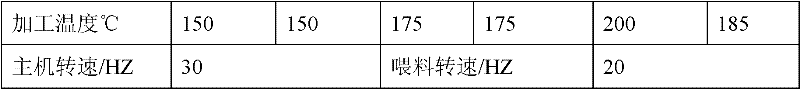

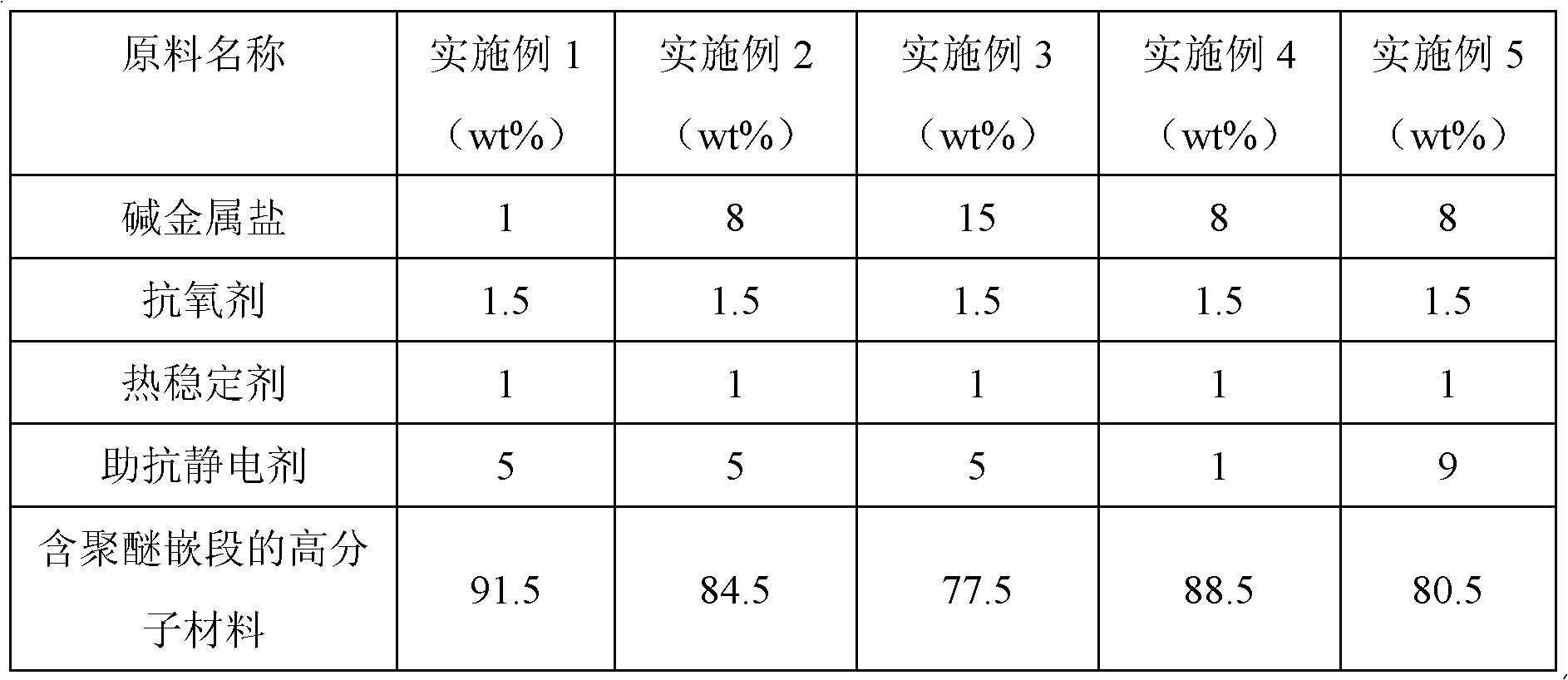

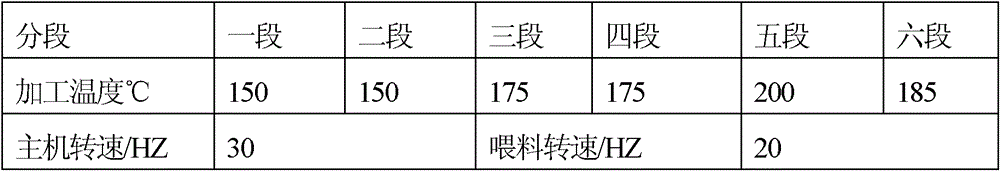

The invention relates to a permanent antistatic master batch and a preparation method thereof. The antistatic master batch comprises the following components in percentage by weight: 1-15 percent of alkali metal salt, 0.5-2 percent of antioxidant, 0.5-2 percent of heat stabilizer, 0-10 percent of assisting antistatic agent and 71-95 percent of polyether block-containing high polymer material, wherein the polyether block-containing high polymer material is a compound consisting of polyethylene glycol oxide and poly(ether ester amide) in the weight ratio 5:1. The preparation method comprises the following steps of: weighing raw materials according to the parts by weight, and putting into a high mixer for mixing for 2-5 minutes; discharging; and extruding and pelletizing with a double screw extruder to obtain the master batch, wherein the processing temperature is 150-200 DEG C, and the number of revolutions of a screw is 25-35 HZ. The invention further relates to a permanent antistatic PA6 / PPO (Polyamide 6 / Polyphenylene Oxide) alloy and a preparation method thereof. The antistatic master batch and the alloy provided by the invention have the advantages of durable antistatic effect, permanent antistatic effect, various colors, low cost and high heat resistance.

Owner:SHANGHAI SUNNY

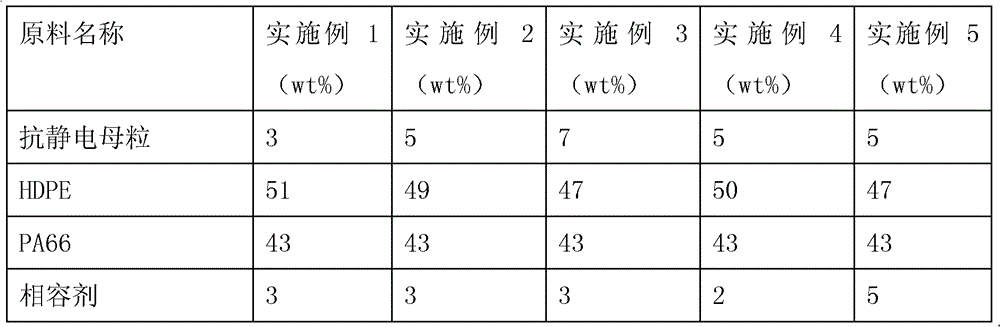

Permanently antistatic PA66/HDPE (Polymide 66/High-density Polyethylene) alloy and preparation method

InactiveCN102399431BImprove antistatic performanceLittle impact on performanceLow-density polyethylenePolymer science

Owner:SHANGHAI SUNNY

Permanent anti-static electricity partes aequales (PA6)/ high-density polyethylene (HDPE) composite material and preparation method thereof

InactiveCN103131169AGood compatibilityImprove antistatic performanceLow-density polyethyleneState of art

The invention relates to a permanent anti-static electricity partes aequales (PA6) / high-density polyethylene (HDPE) alloy and a preparation method of the permanent anti-static electricity PA6 / HDPE alloy. The alloy material comprises the following components and part by weight contents: 3-8 parts of a self-control anti-static electricity master batch, 640-43 parts of the PA6 , 40-52 parts of the HDPE and 1-5 parts of a compatilizer . Raw materials are weighed and taken according to the weight ratio. The raw materials are placed in a high mixing machine and the raw materials are blended for 2-5 minutes. The raw materials are discharged. Then pelletings are squeezed from a double screw rod extruder. The machining temperature is 190-215 DEG C. The number of revolutions of a screw rod is 35-40 HZ. Compared with the prior art, the permanent anti-static electricity PA6 / HDPE alloy has the advantages that the anti-static electricity effect is permanent and the effect of permanent anti-static electricity is achieved. The anti-static electricity effect is good. Analyse mechaniscs performance is high. The permanent anti-static electricity PA6 / HDPE alloy is close to the pure HDPE performance. Color is light. The permanent anti-static electricity PA6 / HDPE alloy can be matched to various kinds of colors. The permanent anti-static electricity HDPE composite material has the advantages of being low in cost, good in heat resistance and the like. Surface electrical resistivity of the permanent anti-static electricity PA6 / HDPE alloy can be arrived at 106-108 omega-m.

Owner:SHANGHAI SUNNY

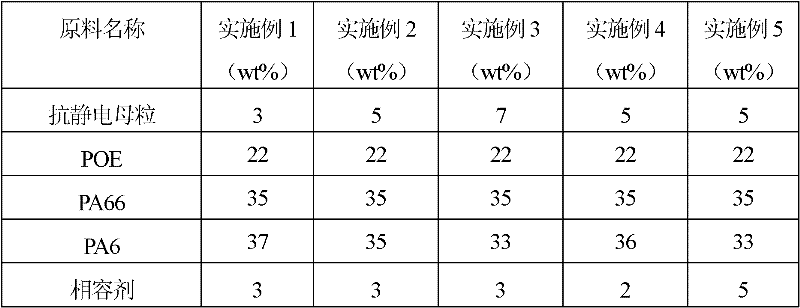

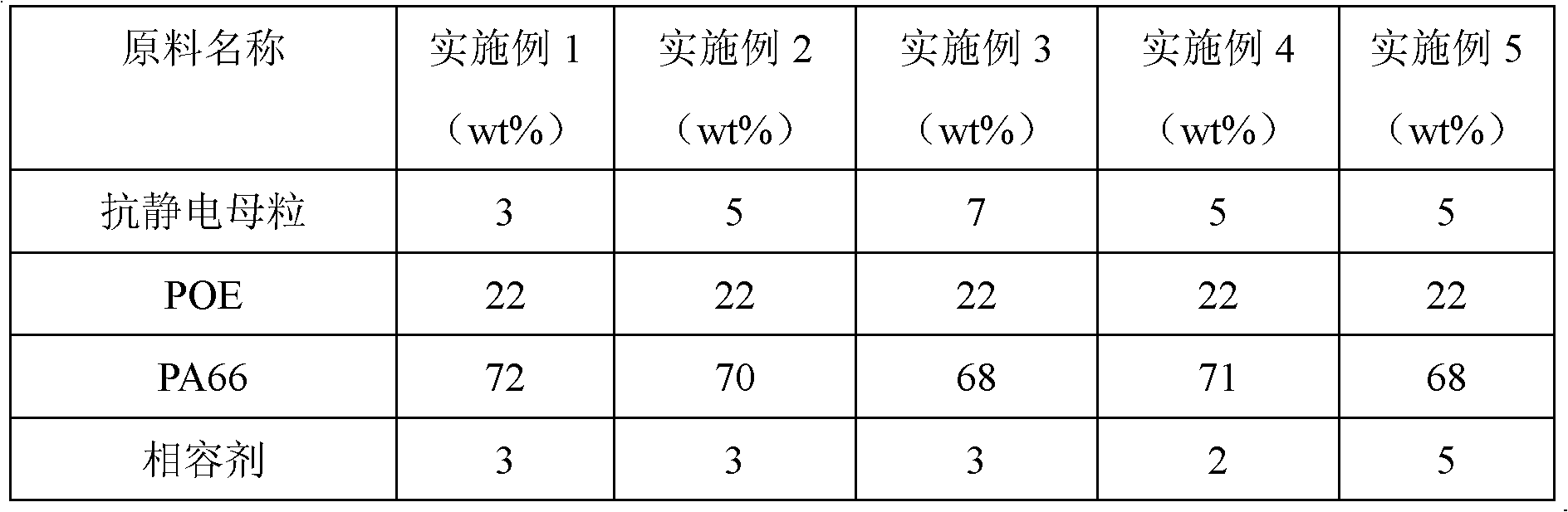

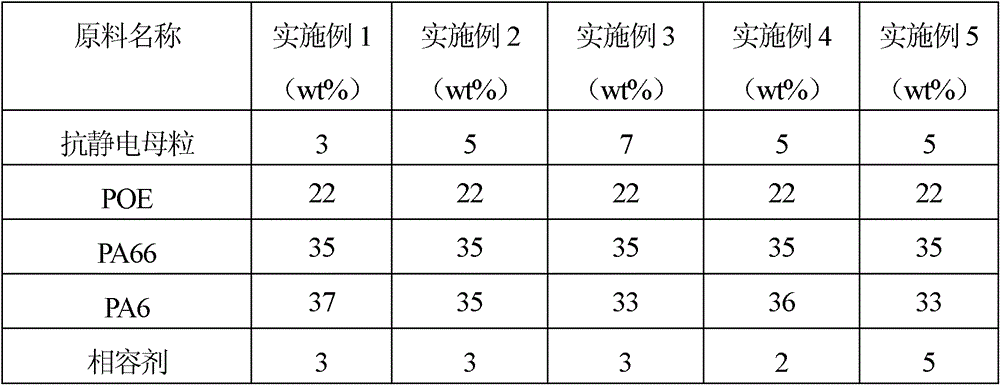

Permanently antistatic masterbatch, permanently antistatic PA66/PA 6/POE (Polymide 66/Polymide 6/ Polyethylene Octene Elastomer) alloy and preparation method

The invention provides an antistatic masterbatch, which comprises the following components: 1-15 wt% of alkaline metal salt, 0.1-2 wt% of antioxidant, 0.1-2 wt% of heat stabilizer, 0.01-10 wt% of assistant antistatic agent and 71-95 wt% of high polymer material with polyether blocks. The invention also provides antistatic alloy prepared from the masterbatch, which comprises the following components: 2-8 wt% of antistatic masterbatch, 20-50 wt% of PA66 (Polymide 66), 20-50 wt% of PA6 (Polymide 6), 15-25 wt% of POE (Polyethylene Octene Elastomer) and 1-5 wt% of compatilizer. The invention also provides a preparation method of the masterbatch and a preparation method of the alloy, which respectively comprise the following steps of: mixing the components for 1-10 minutes; discharging; extruding; pelleting; and obtaining the product. The antistatic masterbatch has the surface resistivity being 102-103 ohm m, a lasting antistatic effect, less additive amount, and good compatibility with many kinds of resin. The antistatic alloy has the surface resistivity being 106-108 ohm m, higher comprehensive mechanical property, low cost and good heat resistance.

Owner:SHANGHAI SUNNY

Polyurethane spray-coating composite material for storage tank thermal insulation and preparation method thereof

ActiveCN102936326BHigh compressive strengthImprove performancePolyurea/polyurethane coatingsPolyesterFoaming agent

The invention relates to a polyurethane spray-coating composite material for storage tank thermal insulation and a preparation method thereof. The composite material is composed of a component A and a component B in a weight ratio of 1:(1-1.05), wherein the component A is composed of polyether glycol A, polyether glycol B, polyester polyol, foam stabilizer, chemical foaming agent, physical foaming agent, catalyst, flame retardant and other assistants; and the component B is polymethylene polyphenyl polyisocyanate. The preparation method comprises the following steps: sequentially adding the components in the component A into a reaction kettle, and thoroughly mixing for 0.5-1 hour at normal temperature; and evenly mixing the component A and the component B in a weight ratio of 1:(1-1.05) with a high-pressure spray coater, atomizing, foaming, and quickly forming and aging the foam to obtain the product. The foam provided by the invention has the advantages of environmental protection, low heat conductivity coefficient and high flame retardancy, and is especially suitable for thermal insulation construction of tank bodies.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Permanent anti-static electricity partes aequales (PA6)/ polyolefin elastomer (POE) alloy and preparation method thereof

The invention relates to a permanent anti-static electricity partes aequales (PA6) / polyolefin elastomer (POE) alloy and a preparation method of the permanent anti-static electricity PA6 / POE alloy. The alloy material comprises the following components and part by weight contents: 3-8 parts of a self-control anti-static electricity master batch, 40-75 parts of the PA6, 15-25 parts of the POE and 1-5 parts of a compatilizer . Raw materials are weighed and taken according to the weight ratio. The raw materials are placed in a high mixing machine and the raw materials are blended for 2-5 minutes. The raw materials are discharged. Then pelletings are squeezed from a double screw rod extruder. The machining temperature is 190-205 DEG C. The number of revolutions of a screw rod is 35-40 HZ. Compared with the prior art, the permanent anti-static electricity PA6 / POE alloy has the advantages that the anti-static electricity effect is permanent and the effect of permanent anti-static electricity is achieved. The anti-static electricity effect is good. Analyse mechaniscs performance is high. The permanent anti-static electricity PA6 / HDPE alloy is close to the pure PA6 / POE alloy performance. Color is light. The permanent anti-static electricity PA6 / POE alloy can be matched to various kinds of colors. The permanent anti-static electricity PA6 / POE has the advantages of being low in cost, good in heat resistance and the like. Surface electrical resistivity of the permanent anti-static electricity PA6 / POE alloy can be arrived at 106-108 omega-m.

Owner:SHANGHAI SUNNY

Permanent anti-static PP (polypropylene) composite material and preparation method thereof

ActiveCN102399393BLittle impact on performanceGood performance impactOther chemical processesHeat resistanceSurface resistivity

The invention relates to a permanent anti-static PP (polypropylene) composite material and a preparation method thereof. The material comprises the following components in percentage by weight: 3 to 8 percent of anti-static master batch, 80 to 95 percent of PP and 1 to 5 percent of compatilizer. The preparation method comprises the following steps of: weighing the raw materials according to weight proportion; placing the raw materials into a high mixing machine to mix the raw materials for 2 to 5 minutes; discharging; and then carrying out extrusion pelletizing by a double-screw extruder, wherein a processing temperature is in the range of 190 to 220 DEG C and screws have revolution of 35 to 40Hz. Compared with the prior art, the permanent anti-static PP composite material has the advantages of sustained anti-static effect, permanent anti-static effect, good anti-static effect, high comprehensive mechanical property, performance close to pure PP, light color, capability of being prepared into various colors, low cost, good heat resistance and the like. The surface resistivity of the permanent anti-static PP composite material can reach 106 to 108 ohm.m.

Owner:上海日之升科技有限公司

Permanent antistatic PA6/PPO (Polyamide 6/Polyphenylene Oxide) alloy and preparation method thereof

InactiveCN102417711BImprove antistatic performanceLittle impact on performancePolyamidePolyethylene glycol

The invention relates to a permanent antistatic master batch and a preparation method thereof. The antistatic master batch comprises the following components in percentage by weight: 1-15 percent of alkali metal salt, 0.5-2 percent of antioxidant, 0.5-2 percent of heat stabilizer, 0-10 percent of assisting antistatic agent and 71-95 percent of polyether block-containing high polymer material, wherein the polyether block-containing high polymer material is a compound consisting of polyethylene glycol oxide and poly(ether ester amide) in the weight ratio 5:1. The preparation method comprises the following steps of: weighing raw materials according to the parts by weight, and putting into a high mixer for mixing for 2-5 minutes; discharging; and extruding and pelletizing with a double screw extruder to obtain the master batch, wherein the processing temperature is 150-200 DEG C, and the number of revolutions of a screw is 25-35 HZ. The invention further relates to a permanent antistatic PA6 / PPO (Polyamide 6 / Polyphenylene Oxide) alloy and a preparation method thereof. The antistatic master batch and the alloy provided by the invention have the advantages of durable antistatic effect, permanent antistatic effect, various colors, low cost and high heat resistance.

Owner:SHANGHAI SUNNY

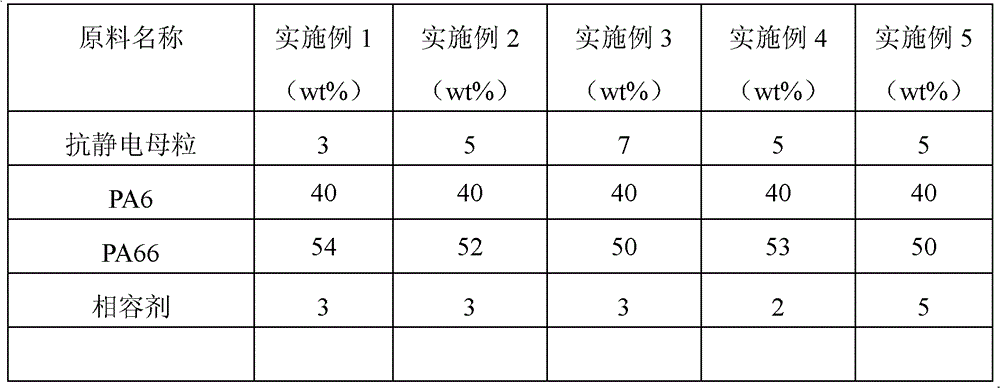

Permanently antistatic PA6/PA 66 (Polymide 6/Polymide 66) alloy and preparation method

InactiveCN102399430BLittle impact on performanceSmall but good antistatic effect Performance impactMasterbatchAntistatic agent

The invention relates to a permanently antistatic masterbatch and a preparation method. The masterbatch comprises the following components in percentage by weight: 1-15% of alkaline metal salt, 0.1-2% of antioxidant, 0.1-2% of heat stabilizer, 0-10% of assistant antistatic agent, and 70-95% of high polymer material with polyether blocks. The invention also relates to permanently antistatic PA6 / PA66 (Polymide 6 / Polymide 66) alloy, which comprises the following components in percentage by weight: 3-8% of anti-static masterbatch, 40-45% of PA6, 40-50% of PA66 and 1-5% of compatilizer. The permanently antistatic masterbatch is prepared by the following steps of: mixing the components; extruding; pelleting; and obtaining the product. The surface resistivity of the masterbatch can reach 102-103ohm m, and the surface resistivity of the PA6 / PA66 alloy can reach 106-108 ohm m. The invention has the advantages that the antistatic effect is lasting, the permanently antistatic effect is achieved, the antistatic effect is good, the comprehensive mechanical property is higher, the color is light and can be prepared into various colors, the cost is low, and the heat resistance is good.

Owner:SHANGHAI SUNNY

Composite micro-electro-mechanical system (MEMS) high-temperature resistant ultrahigh-pressure sensor

InactiveCN102012288BLower requirementHigh resistance coefficientForce measurementEngineeringElectric cables

The invention discloses a composite micro-electro-mechanical system (MEMS) high-temperature resistant ultrahigh-pressure sensor. The sensor comprises a base, a silicon beam sensitive element, a high-temperature adapter plate and a shell, wherein the shell is assembled on the base; the silicon beam sensitive element is connected to a high-temperature cable through a gold wire lead and the high-temperature adapter plate and is connected with an external circuit; the base is combined with a foundation support through a pressure-bearing elastic element; the middle of the pressure-bearing elastic element is provided with a circular membrane which is provided with a dowel bar; the silicon beam sensitive element has an E-shaped cup structure of which the middle is provided with a measuring island; the silicon beam sensitive element is assembled on the pressure-bearing elastic element; the measuring island is contacted with the dowel bar; pressure is applied to the circular membrane so as to deform the circular membrane; deflection is applied to the measuring island; and constant current or voltage is processed by the silicon beam sensitive element, and an electric signal which is proportional to a tested pressure is output and transmitted to the external circuit through the gold wire lead, the high-temperature adapter plate and the high-temperature cable so as to realize measurement of the tested pressure. The sensor has the advantages of large measuring range, wide application range, high sensitivity, high signal to noise ratio and the like.

Owner:XI AN JIAOTONG UNIV

Permanent anti-static electricity partes aequales (PA6)/ high-density polyethylene (HDPE) composite material and preparation method thereof

InactiveCN103131169BGood compatibilityImprove antistatic performanceLow-density polyethyleneHeat resistance

The invention relates to a permanent anti-static electricity partes aequales (PA6) / high-density polyethylene (HDPE) alloy and a preparation method of the permanent anti-static electricity PA6 / HDPE alloy. The alloy material comprises the following components and part by weight contents: 3-8 parts of a self-control anti-static electricity master batch, 640-43 parts of the PA6 , 40-52 parts of the HDPE and 1-5 parts of a compatilizer . Raw materials are weighed and taken according to the weight ratio. The raw materials are placed in a high mixing machine and the raw materials are blended for 2-5 minutes. The raw materials are discharged. Then pelletings are squeezed from a double screw rod extruder. The machining temperature is 190-215 DEG C. The number of revolutions of a screw rod is 35-40 HZ. Compared with the prior art, the permanent anti-static electricity PA6 / HDPE alloy has the advantages that the anti-static electricity effect is permanent and the effect of permanent anti-static electricity is achieved. The anti-static electricity effect is good. Analyse mechaniscs performance is high. The permanent anti-static electricity PA6 / HDPE alloy is close to the pure HDPE performance. Color is light. The permanent anti-static electricity PA6 / HDPE alloy can be matched to various kinds of colors. The permanent anti-static electricity HDPE composite material has the advantages of being low in cost, good in heat resistance and the like. Surface electrical resistivity of the permanent anti-static electricity PA6 / HDPE alloy can be arrived at 106-108 omega-m.

Owner:SHANGHAI SUNNY

Permanent anti-static electricity partes aequales (PA6)/ polyolefin elastomer (POE) alloy and preparation method thereof

Owner:SHANGHAI SUNNY

Permanently antistatic polyamide 66/polypropylene (PA66/PP) alloy, and preparation method thereof

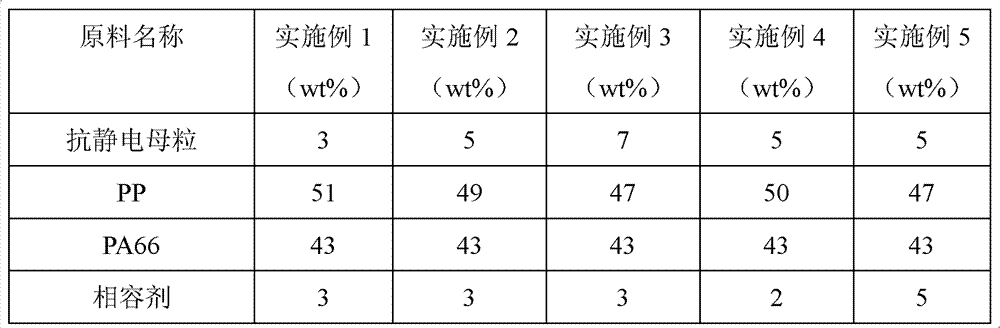

The invention relates to a permanently antistatic polyamide 66 / polypropylene (PA66 / PP) alloy, and a preparation method thereof. The material comprises the following components in percentage by weight: 3 to 8 percent of antistatic masterbatch, 40 to 43 percent of PA66, 40 to 52 percent of PP and 1 to 5 percent of compatilizer, wherein the masterbatch comprises the following components in percentage by weight: 1 to 15 percent of alkali metal salt, 0.1 to 2 percent of antioxidant, 0.1 to 2 percent of heat stabilizer, 0 to 10 percent of antistatic aid and 70 to 95 percent of polymer material containing a polyether block. The preparation method comprises the following steps of: weighing raw materials in the weight proportion, mixing, discharging, and performing extrusion granulation. The alloy has the advantages of good and durable antistatic effect, high comprehensive mechanical property, low cost, high heat resistance and the like, and achieves a permanent antistatic effect, the performance of the alloy is close to that of a pure PA66 / PP alloy, and the color of the alloy is light and can be prepared into various colors. The surface resistivity of the permanently antistatic PA66 / PP alloy can reach 106 to 108ohm.m.

Owner:SHANGHAI SUNNY

A cylindrical ultra-high pressure sensor with side cavity oil-filled structure

InactiveCN103196617BIncrease rangeOvercome the shortcoming of small measuring range of structureFluid pressure measurement using ohmic-resistance variationElectrical resistance and conductanceUltra high pressure

A cylinder type ultra-high-pressure sensor of a side cavity oil charging structure comprises an elastic element base, wherein the upper portion of the elastic element base is a pressure bearing cylinder, a pressure bearing hole is formed in the center of the pressure bearing cylinder, and the side wall of the pressure bearing cylinder is provided with one or more than one oil charging cavity. A Wheatstone bridge of a sensitive element is connected with a patch board through a gold wire lead, one end of a cable is connected with the output of the patch board, the other end of the cable is connected with an external circuit, incompressible silicone oil is filled in the oil charging cavity, pressure of measured media directly acts inside the pressure bearing hole, the oil charging cavity produces size deformation which is directly proportional to the measured pressure, and the deformation is transmitted to the sensitive element through the incompressible silicone oil. On the basis of the monocrystalline silicon piezoresistive effect, resistance of four voltage dependent resistors on the sensitive element changes, under drive of a stabilized power source, the four voltage dependent resistors constitute the Wheatstone bridge to output electric signals which are directly proportional to the measured pressure, and therefore detection of ultra-high-pressure can be conducted. The cylinder type ultra-high-pressure sensor can bear pressure more than 1.5 GPa.

Owner:XI AN JIAOTONG UNIV

Permanent antistatic polybutylene terephthalate (PBT)/poly-p-phenylene oxide (PPO) alloy and production method thereof

InactiveCN102417716BLittle impact on performanceSmall but good antistatic effect Performance impactMasterbatchAntistatic agent

Owner:SHANGHAI SUNNY

Permanent anti-static polyamide 66 (PA66) composite material and preparation method thereof

The invention relates to a permanent anti-static polyamide 66 (PA66) composite material and a preparation method thereof. The material comprises the following components in percentage by weight: 3 to 8 percent of anti-static masterbatch, 80 to 95 percent of PA66 and 1 to 5 percent of compatilizer, wherein the anti-static masterbatch comprises the following components in percentage by weight: 1 to 15 percent of alkali metal salt, 0.1 to 2 percent of antioxidant, 0.1 to 2 percent of heat stabilizer, 0 to 10 percent of anti-static aid and 70 to 95 percent of high molecular material containing a polyether block. The preparation method comprises the following steps of: weighing the raw materials in the weight ratio; discharging; and extruding and pelleting. The permanent anti-static PA66 composite material has the advantages that: the anti-static effect is durable; a permanent anti-static effect is achieved; the anti-static effect is good; comprehensive mechanical properties are high and close to the properties of pure PA66; colors are light, so the material can be prepared into various colors; cost is low; and heat resistance is high and the like. The surface resistivity of the permanent anti-static PA66 composite material is 10<6> to 10<8> ohm.m.

Owner:SHANGHAI SUNNY

A kind of permanent antistatic ABS composite material and preparation method thereof

The invention relates to a permanent anti-static electricity acrylonitrile butadiene styrene (ABS) composite material and a preparation method of the permanent anti-static electricity ABS composite material. The material comprises the following components and part by weight contents: 3-8 parts of a self-control anti-static electricity master batch, 80-95 parts of the ABS and 1-5 parts of a compatilizer. Raw materials are weighed and taken according to the weight ratio. The raw materials are placed in a high mixing machine and the raw materials are blended for 2-5 minutes. The raw materials are discharged. Then pelletings are squeezed from a double screw rod extruder. The machining temperature is 190-225 DEG C. The number of revolutions of a screw rod is 35-40 HZ. Compared with the prior art, the permanent anti-static electricity ABS composite material has the advantages that the anti-static electricity effect is permanent and the effect of permanent anti-static electricity is achieved. The anti-static electricity effect is good. Analyse mechaniscs performance is high. The permanent anti-static electricity ABS composite material is close to the pure ABS performance. Color is light. The permanent anti-static electricity ABS composite material can be matched to various kinds of colors. The permanent anti-static electricity ABS composite material has the advantages of being low in cost, good in heat resistance and the like. Surface electrical resistivity of the permanent anti-static electricity ABS composite material can be arrived at 106-108 omega-m.

Owner:SHANGHAI SUNNY

PP/PPO alloy with permanent antistatic performance and preparation method thereof

InactiveCN102417719BLittle impact on performanceSmall but good antistatic effect Performance impactHeat resistanceSurface resistivity

The invention relates to PP / PPO alloy with permanent antistatic performance and a preparation method thereof. The alloy comprises the following components by weight percent: 3 to 8% of antistatic master batches, 40 to 45% of PP, 40 to 50% of PPO and 1 to 5% of a compatilizer, and is prepared by weighing the above-mentioned raw materials by weight, putting the raw materials into a high-speed mixer for mixing for 2 to 5 min, discharging a material and carrying out extrusion and granulation on the material with a double-screw extruder, with processing temperature to be 245 to 285 DEG C and the revolution of screws to be 35 to 40 Hz. The PP / PPO alloy provided in the invention has a lasting antistatic effect, realizes a permanent antistatic effect, has the advantages of a good antistatic effect, high comprehensive mechanical properties, performance close to that of pure PP / PPO alloy, a light color capable of being blended into a variety of colors, low cost, good heat resistance, etc., and has surface resistivity up to 106 to 108 omega.m.

Owner:SHANGHAI SUNNY

Permanently antistatic PA66/PPO (Polymide 6/Poly-p-Phenylene Oxide) alloy and preparation method

InactiveCN102399441ALong-lasting antistatic effectGood antistatic effectOther chemical processesSurface resistivityOhm

The invention relates to permanently antistatic PA66 / PPO (Polymide 6 / Poly-p-Phenylene Oxide) alloy and a preparation method. The permanently antistatic PA66 / PPO alloy comprises the following components in percentage by weight: 3-8% of antistatic masterbatch, 40-45% of PA66, 40-50% of PPO and 1-5% of compatibilizer, wherein the antistatic masterbatch comprises the following components by weight percentage: 1-15% of alkaline metal salt, 0.1-2% of antioxidant, 0.1-2% of heat stabilizer, 0-10% of assistant antistatic agent and 70-95% of high polymer material with polyether blocks. The preparation comprises the following steps of: weighing raw material according to the weight ratio; mixing the raw materials; discharging; extruding; pelleting; and obtaining the product. The invention has the advantages that the antistatic effect is lasting, the permanently antistatic effect is achieved, the antistatic effect is good, the comprehensive mechanical property is higher and is close to the property of the pure PA66 / PPO alloy, the color is light and can be prepared into various colors, the cost is low, the heat resistance is good, and the like. The surface resistivity of the alloy can reach 106-108 ohm m.

Owner:SHANGHAI SUNNY

Permanent antistatic PA66/POE (Polyamide 66/Polyolefin Elastomer) alloy and preparation method thereof

Owner:SHANGHAI SUNNY

Permanently antistatic masterbatch, permanently antistatic PA66/PA 6/POE (Polymide 66/Polymide 6/ Polyethylene Octene Elastomer) alloy and preparation method

The invention provides an antistatic masterbatch, which comprises the following components: 1-15 wt% of alkaline metal salt, 0.1-2 wt% of antioxidant, 0.1-2 wt% of heat stabilizer, 0.01-10 wt% of assistant antistatic agent and 71-95 wt% of high polymer material with polyether blocks. The invention also provides antistatic alloy prepared from the masterbatch, which comprises the following components: 2-8 wt% of antistatic masterbatch, 20-50 wt% of PA66 (Polymide 66), 20-50 wt% of PA6 (Polymide 6), 15-25 wt% of POE (Polyethylene Octene Elastomer) and 1-5 wt% of compatilizer. The invention also provides a preparation method of the masterbatch and a preparation method of the alloy, which respectively comprise the following steps of: mixing the components for 1-10 minutes; discharging; extruding; pelleting; and obtaining the product. The antistatic masterbatch has the surface resistivity being 102-103 ohm m, a lasting antistatic effect, less additive amount, and good compatibility with many kinds of resin. The antistatic alloy has the surface resistivity being 106-108 ohm m, higher comprehensive mechanical property, low cost and good heat resistance.

Owner:SHANGHAI SUNNY

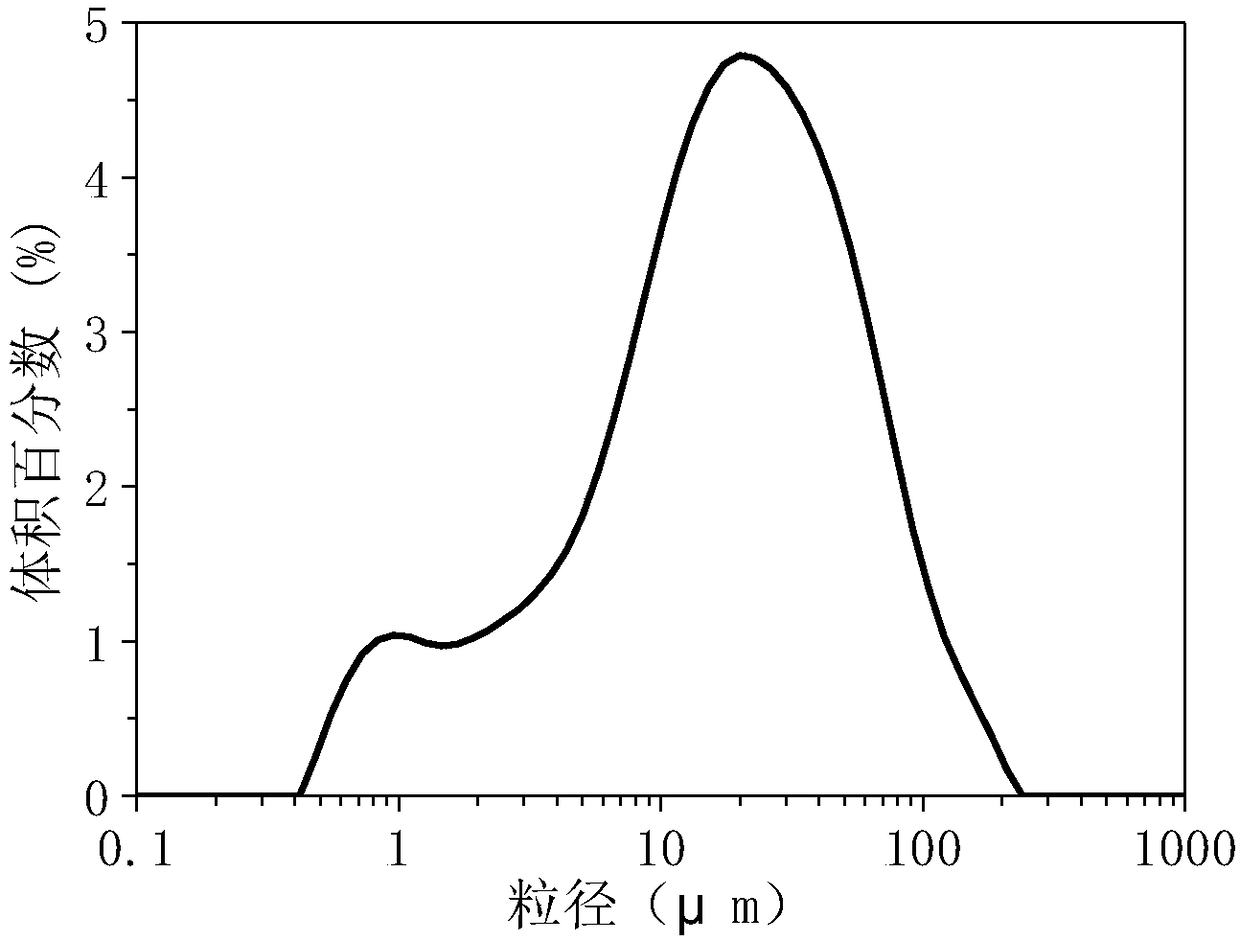

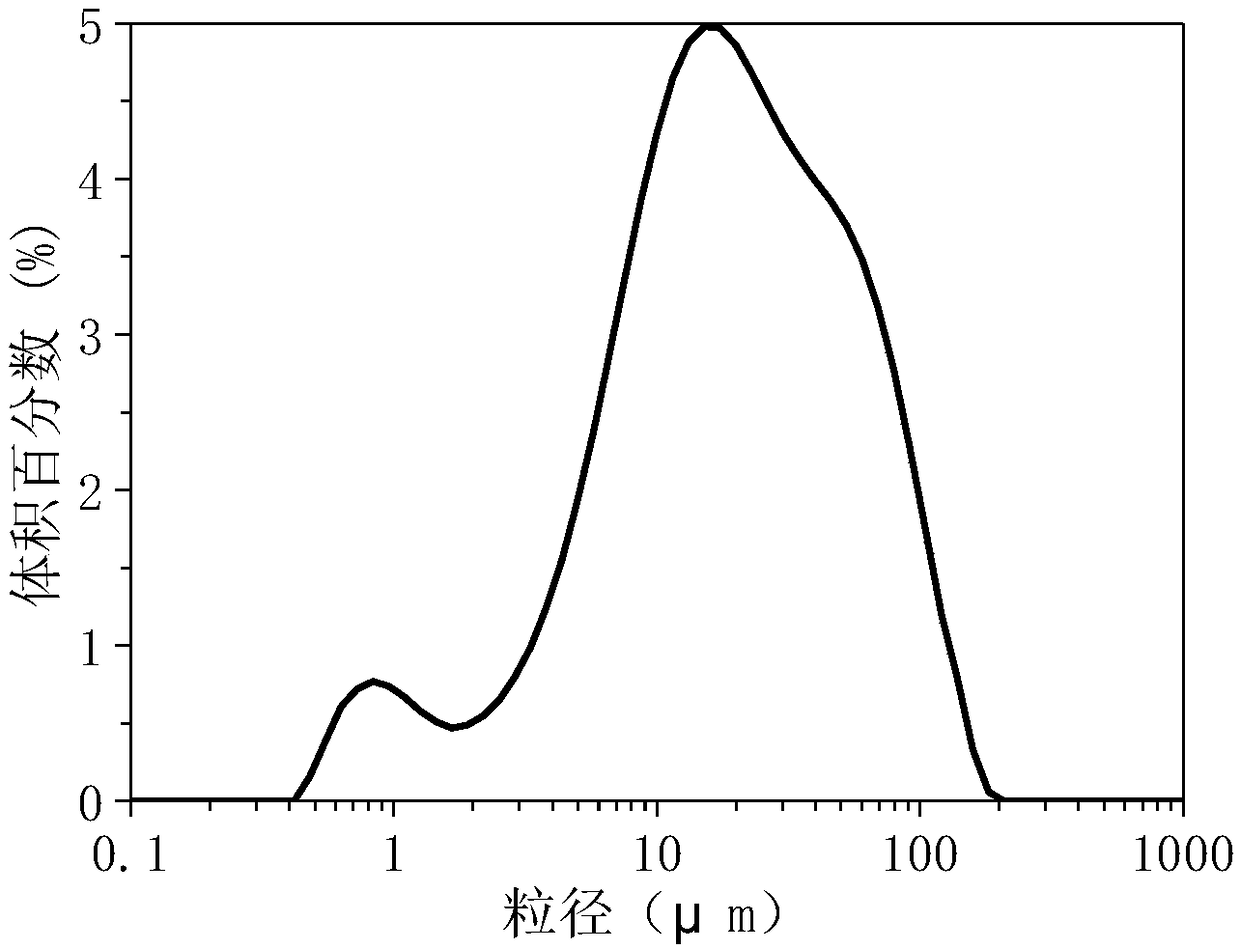

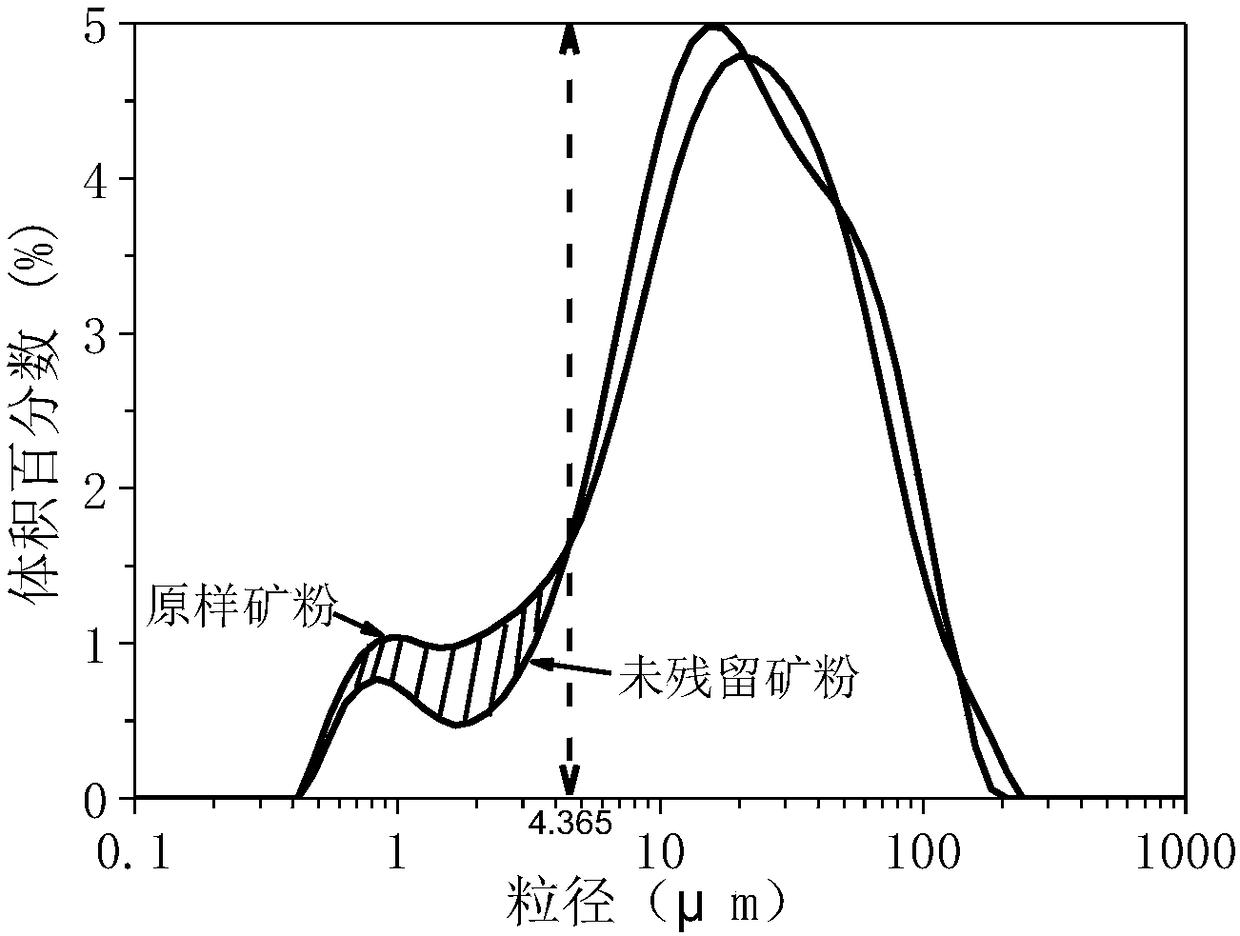

Method for determining composition and content of residual mineral powder in extraction process of asphalt mixture

InactiveCN108106976AGood performance impactImprove uniformityParticle size analysisParticle compositionAsphalt

The invention provides a method for determining composition and content of residual mineral powder in an extraction process of an asphalt mixture. The method comprises the following steps: (1) determining the particle composition and distribution of original mineral powder by a laser particle size analyzer; (2) blending the original mineral powder in (1) with asphalt and aggregate to form the asphalt mixture, and dispersing and cooling the asphalt mixture; (3) extracting the asphalt mixture in (2) by extraction equipment; (4) collecting non-residual mineral powder after extraction, and determining the particle composition and distribution of the non-residual mineral powder by the laser particle size analyzer; (5) comparing the particle composition and distribution of the original mineral powder in (1) and the non-residual mineral powder in (4), determining the composition of the residual mineral powder on the basis of the difference between the two kinds of particle composition, and calculating the content of the residual mineral powder on the basis of integral of the difference between the particle distribution of the two kinds of mineral powder. The method has the advantages of being simple to operate, rapid, efficient, easy to realize, easy to master, apply and popularize and high in data result stability and accuracy, and a measurement result is visual, real and reliable.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com