Permanent antistatic PA6/PPO (Polyamide 6/Polyphenylene Oxide) alloy and preparation method thereof

An antistatic and antistatic masterbatch technology, which is applied in the field of permanent antistatic PA6/PPO alloy and its preparation, can solve the problems of low conductivity and achieve low cost, long-lasting antistatic effect, and small addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

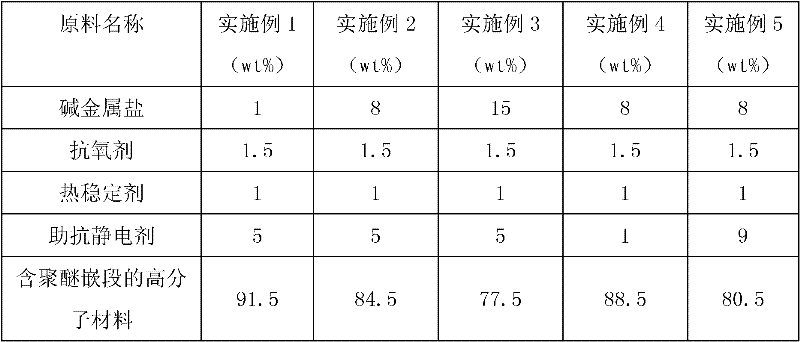

[0030] The raw material formula of embodiment 1-5 is as follows:

[0031]

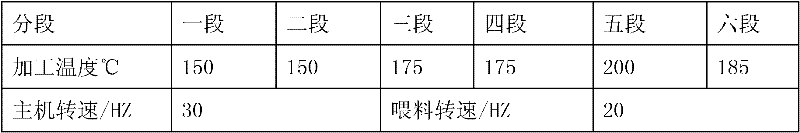

[0032] Put the above components into a high mixer according to the proportion and mix them for 2-5 minutes, discharge the material, and then use a screw extruder to extrude and granulate. The processing temperature is 150-200°C, and the screw speed is 25-35HZ.

[0033]

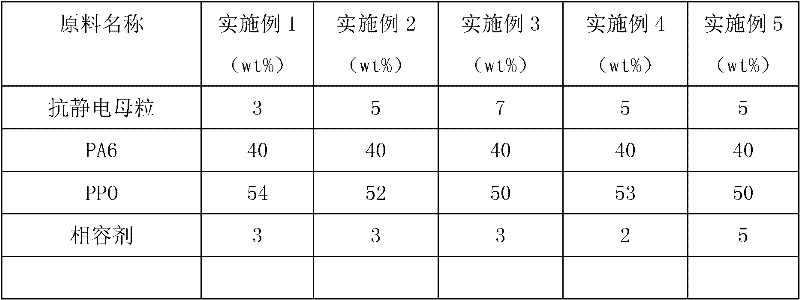

[0034] According to the samples prepared in Examples 1-5, the surface resistivity test was carried out for comparison.

[0035] The test performance comparison is shown in the table below:

[0036] project

[0037] The surface resistivity of the permanent antistatic masterbatch prepared according to the above formula and method reaches 10 2 -10 3 Ω·m, can be widely used in modified PA6 / PPO alloy; compared with the prior art, the present invention has long-lasting antistatic effect, small amount of addition but good antistatic effect, little influence on PA6 / PPO alloy performance, color Shallow, low cost, good heat r...

Embodiment 5

[0038] The permanent antistatic masterbatch prepared in Example 5 has the lowest surface resistivity and the highest cost performance.

Embodiment 6-7

[0051] Embodiment 6-7 is permanent antistatic PA6 / PPO alloy and preparation method thereof

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com