Method for determining composition and content of residual mineral powder in extraction process of asphalt mixture

A technology of asphalt mixture and extraction process, which is applied in the direction of measuring devices, particle size analysis, scientific instruments, etc., can solve the problem that the mineral powder content of asphalt mixture is lower than the real value, and the composition of mineral powder particles cannot be directly tested, which affects the performance evaluation of asphalt Accuracy and other issues, to achieve fast and efficient measurement process, intuitive and reliable detection results, easy to grasp the effect of application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present invention is a method for measuring the composition and content of residual mineral powder in the extraction process of asphalt mixture, comprising the following steps:

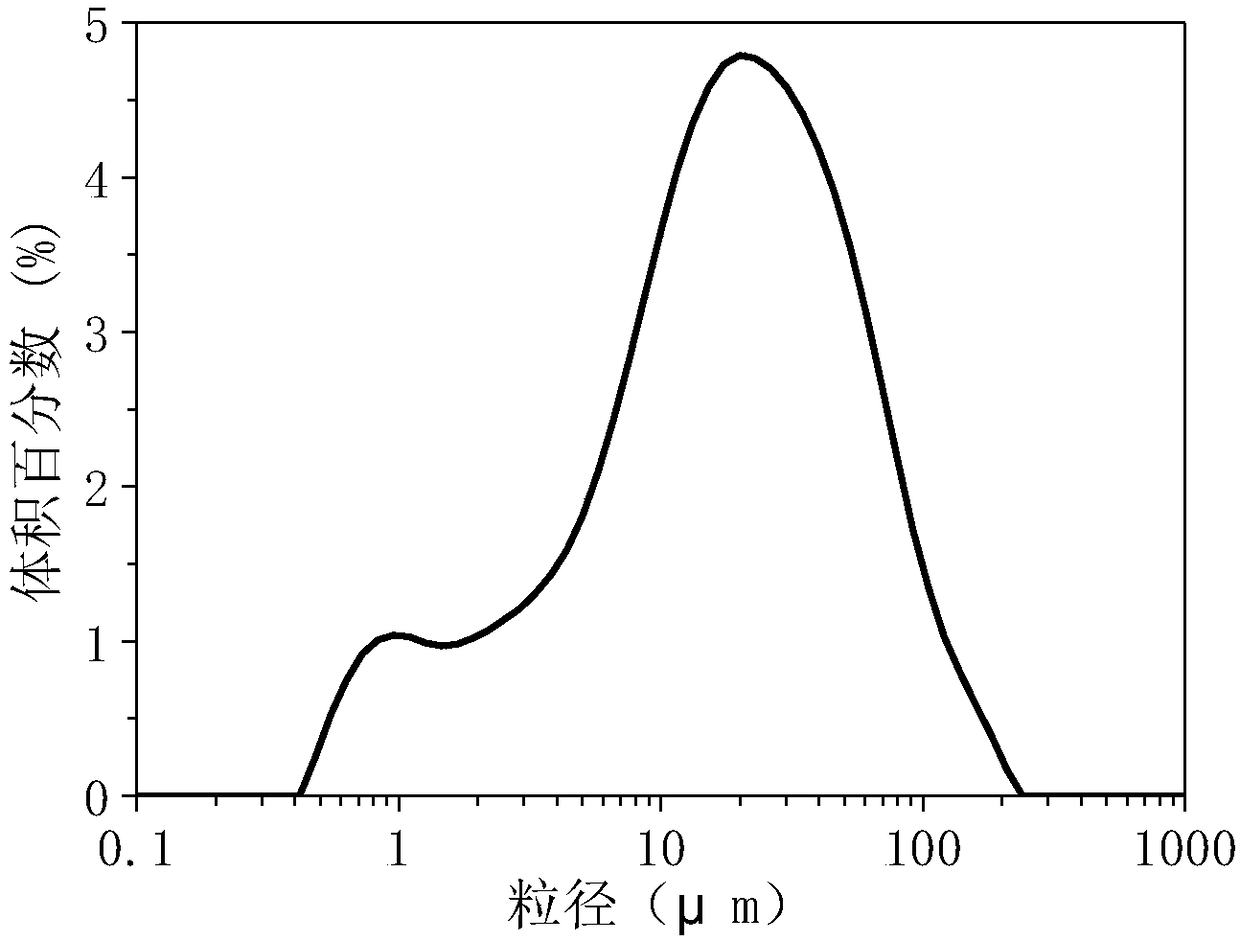

[0038] (1) Use a laser particle size analyzer to measure the particle composition and distribution of the original mineral powder. The test results are shown in figure 1 . The laser particle size analyzer is MS2000 Malvern laser particle size analyzer.

[0039] (2) Mix the raw ore powder in (1) with asphalt and aggregates to form an asphalt mixture, and disperse and cool at room temperature. The original slag powder is limestone slag powder, and the asphalt is SBS modified asphalt. The performance index test results are shown in Table 1.

[0040] Table 1 Test results of performance indicators of SBS modified asphalt

[0041]

[0042]

[0043] Limestone is used as the aggregate, and the test results of its relative density are shown in Table 2.

[0044] Table 2 Aggregate Relative D...

Embodiment 2

[0055] The present invention is a method for measuring the composition and content of residual mineral powder in the extraction process of asphalt mixture, comprising the following steps:

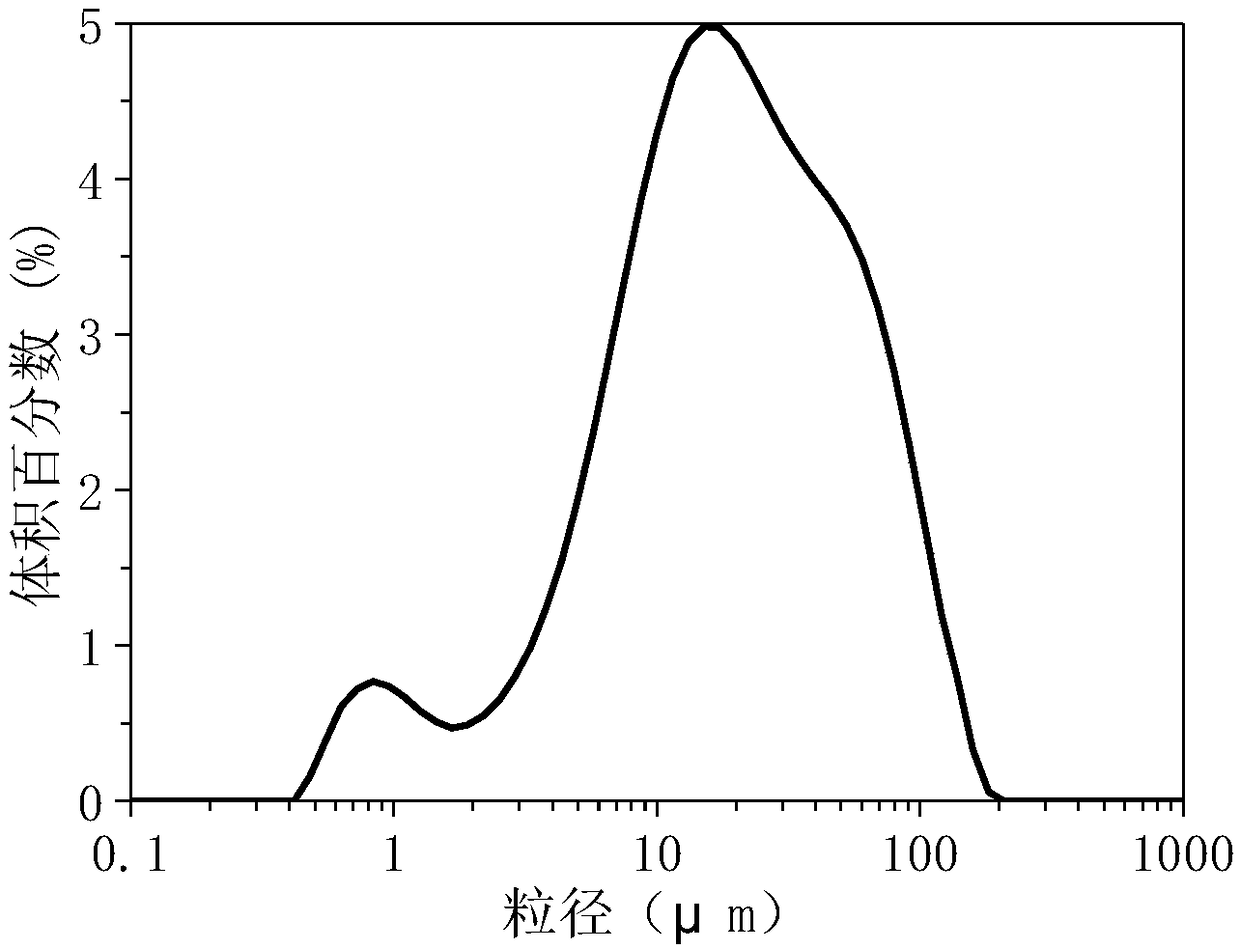

[0056] (1) Use a laser particle size analyzer to measure the particle composition and distribution of the original mineral powder. The test results are shown in Figure 4 . The laser particle size analyzer is MS2000 Malvern laser particle size analyzer.

[0057] (2) Mix the raw ore powder in (1) with asphalt and aggregates to form an asphalt mixture, and disperse and cool at room temperature. The original slag powder is limestone slag powder, and the asphalt is SBS modified asphalt. The performance index test results are shown in Table 4.

[0058] Table 4 SBS modified asphalt performance index test results

[0059] Penetration 25°C (0.1mm)

Softening point (℃)

Ductility 5℃(cm)

46.7

81.6

31.0

[0060] Limestone is used as the aggregate, and the test resul...

Embodiment 3

[0072] The present invention is a method for measuring the composition and content of residual mineral powder in the extraction process of asphalt mixture, comprising the following steps:

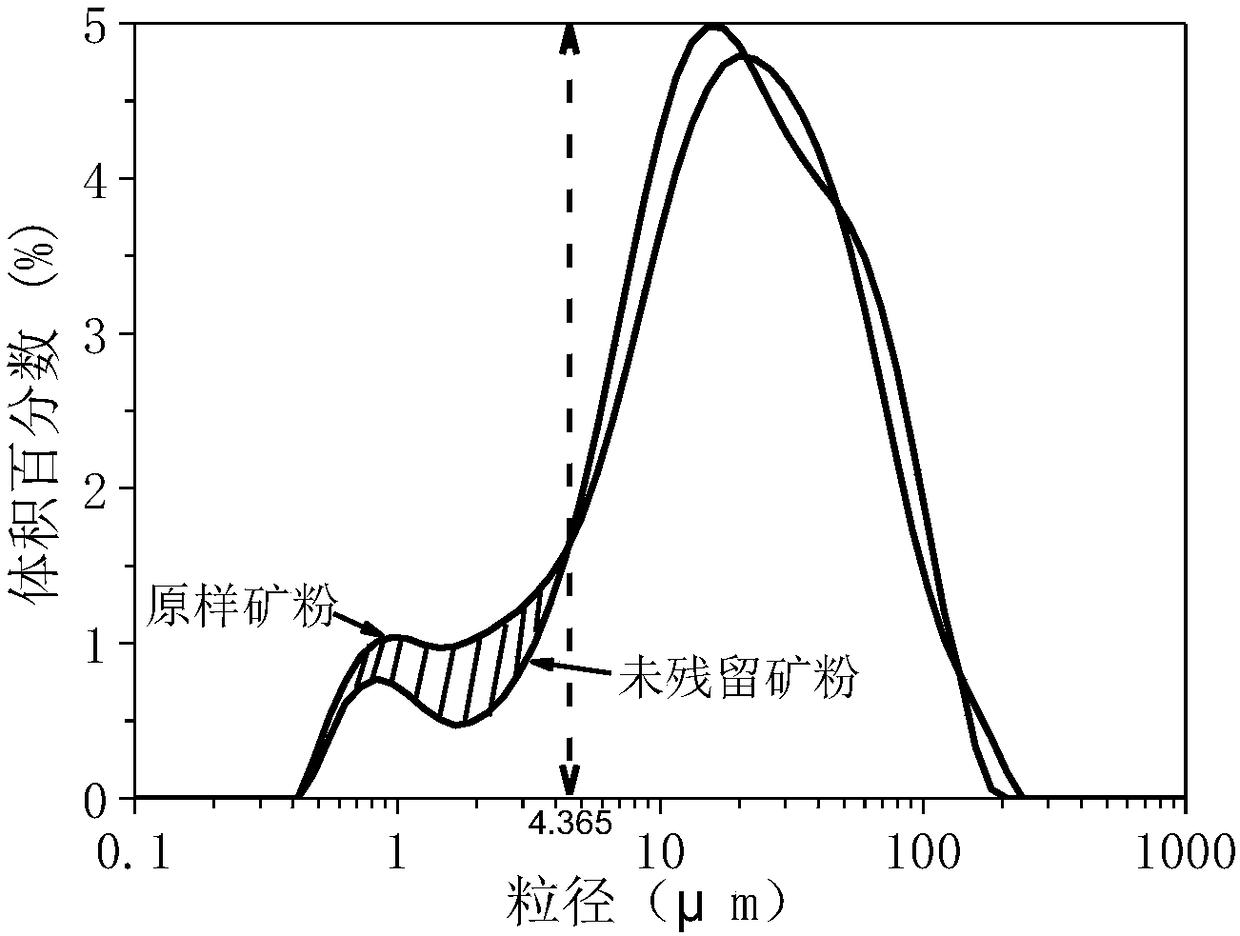

[0073] (1) Use a laser particle size analyzer to measure the particle composition and distribution of the original mineral powder. The test results are shown in Figure 7 . The laser particle size analyzer is MS2000 Malvern laser particle size analyzer.

[0074] (2) Mix the raw ore powder in (1) with asphalt and aggregates to form an asphalt mixture, and disperse and cool at room temperature. The original slag powder is limestone slag powder, and the asphalt is SBS modified asphalt. The performance index test results are shown in Table 7.

[0075] Table 7 SBS modified asphalt performance index test results

[0076] Penetration 25°C (0.1mm)

Softening point (℃)

Ductility 5℃(cm)

46.7

81.6

31.0

[0077] Limestone is used as the aggregate, and the test resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com