A kind of permanent antistatic ABS composite material and preparation method thereof

A composite material and antistatic technology, applied in the field of antistatic composite material and its preparation, can solve problems such as low electrical conductivity, and achieve the effects of low cost, small addition amount, and improved surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

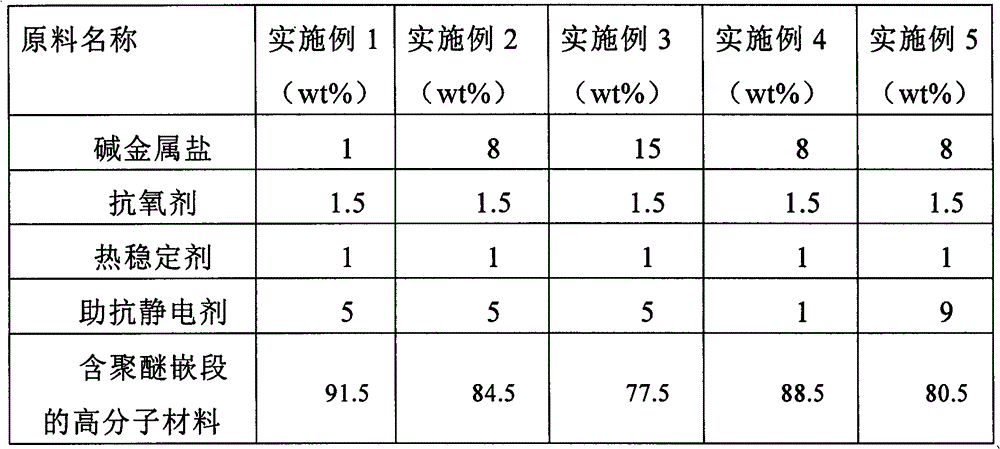

[0027] The raw material formula of antistatic masterbatch in embodiment 1-5 is as follows:

[0028]

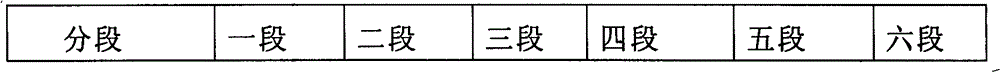

[0029] Put the above components into a high mixer according to the proportion and mix them for 2-5 minutes, discharge the material, and then use a screw extruder to extrude and granulate. The processing temperature is 150-200°C, and the screw speed is 25-35HZ.

[0030]

[0031]

[0032] According to the samples prepared in Examples 1-5, the surface resistivity test was carried out for comparison.

[0033] The test performance comparison is shown in the table below:

[0034] project

[0035] The surface resistivity of the permanent antistatic masterbatch developed according to the above formula and process can reach 10 6 -10 8 Ω.m. can be widely used in modified ABS; compared with the existing technology, it has long-lasting antistatic effect, small amount of addition but good antistatic effect, little impact on ABS performance, light color, low cost, and ...

Embodiment 5

[0036] Example 5 has the lowest surface resistivity and the highest cost performance.

Embodiment 6-10

[0039] The raw material formula of permanent antistatic ABS composite material in embodiment 6-10 is as follows:

[0040]

[0041] Put the above components into a high mixer according to the proportion and mix them for 2-5 minutes, discharge the material, and then use a screw extruder to extrude and granulate. The processing temperature is 190-225°C, and the screw speed is 35-40HZ.

[0042]

[0043] The samples prepared according to Examples 6-10 were compared in performance tests, using ASTM standards.

[0044] The test performance comparison is shown in the table below:

[0045]

[0046]

[0047] Compared with the existing technology, the permanent antistatic ABS composite material developed according to the above formula and process has a long-lasting antistatic effect, achieves a permanent antistatic effect, good antistatic effect, high comprehensive mechanical properties, and is close to the performance of pure ABS. , light color can be made into various colo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com