Permanent anti-static PP (polypropylene) composite material and preparation method thereof

A composite material and antistatic technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem that the conductivity is lower than that of metal materials, achieve good antistatic effect, improve compatibility, and increase surface activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

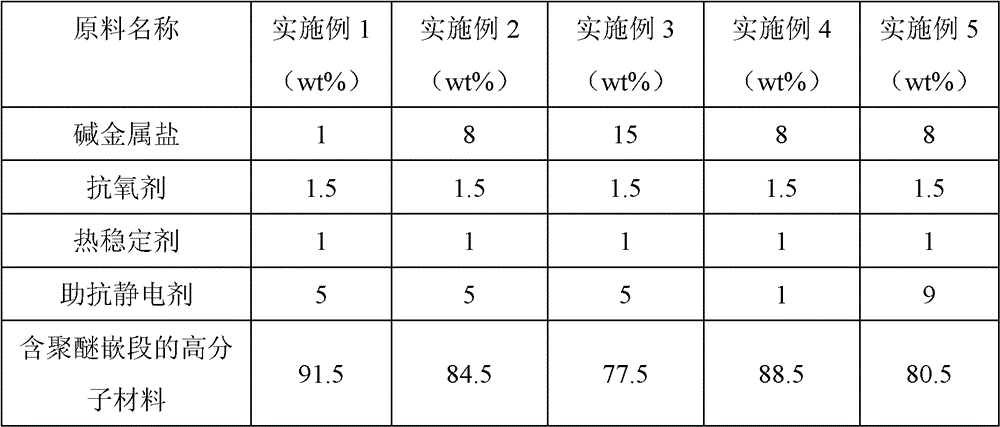

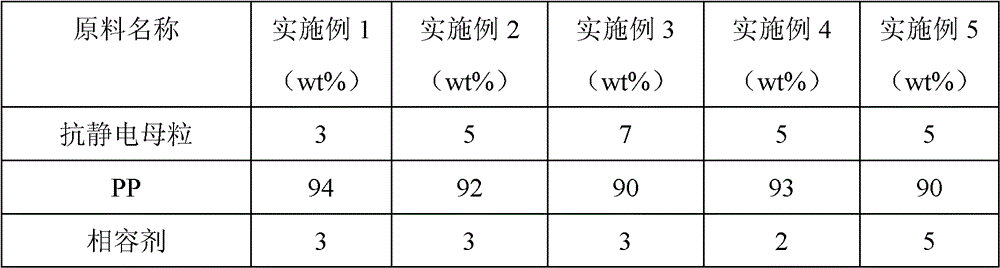

[0023] The antistatic masterbatch raw material formula of embodiment 1-5 is as follows:

[0024]

[0025] In the foregoing examples, the alkali metal salt is M + x - , where M + for Li + , Na + , K + ;X - for Cl - 、Br - , I - 、CLO 4 - , preferably LiCLO 4 .

[0026] In the above examples, the antioxidant is a 1:1 compound of phenothiazine and phosphite (s9228);

[0027] In the foregoing examples, the heat stabilizer is a compound of organotin heat stabilizer, calcium stearate, and zinc stearate in a ratio of 2:1:1;

[0028] In the foregoing embodiments, the auxiliary antistatic agent is silicon dioxide;

[0029] In the above examples, the polymer material containing polyether block is a compound of polyethylene oxide and polyethylene glycol methacrylic acid copolymer in a ratio of 5:1; the molecular weight of the two polymers is preferably 6- Between 160,000.

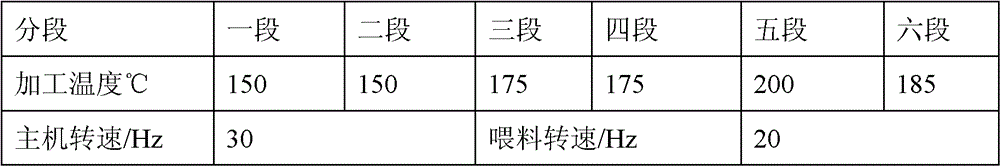

[0030] Put the above components into a high mixer according to the proportion and mix them for 2-5...

Embodiment 5

[0036] Example 5 has the lowest surface resistivity and the highest cost performance.

Embodiment 6

[0051] Weigh the raw materials according to the weight ratio: 1% of the antistatic masterbatch mentioned above, 98% of PP, 1% of the compatibilizer, weigh the raw materials according to the weight ratio, put them into the high mixer and mix them for 2-5 minutes, discharge, Then use a twin-screw extruder to extrude and granulate, the processing temperature is 190-220 ° C, and the screw rotation speed is 40 Hz. The surface resistivity of the prepared material is 10 13 Ω.m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com