Permanently antistatic PA6/PA 66 (Polymide 6/Polymide 66) alloy and preparation method

An antistatic and antistatic masterbatch technology, applied in the field of permanent antistatic PA6/PA66 alloy preparation, can solve problems such as low conductivity, and achieve the effects of low cost, light color, and improved comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

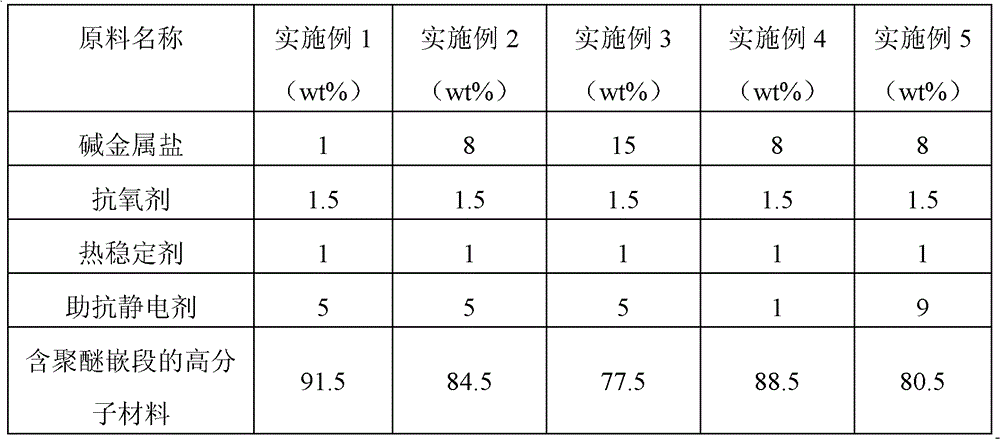

[0026] The permanent antistatic masterbatch raw material formula of embodiment 1-5 is as follows:

[0027]

[0028] In the foregoing examples, the alkali metal salt is M + x - , where M + for Li + , Na + , K + ;X - for Cl - 、Br - , I - 、CLO 4 - .

[0029] In the above examples, the antioxidant is a compound of phenothiazine and phosphite in a weight ratio of 1:1.

[0030] In the above examples, the heat stabilizer is a compound of organotin heat stabilizer, calcium stearate and zinc stearate in a weight ratio of 2:1:1.

[0031] In the above examples, the auxiliary antistatic agent is silicon dioxide.

[0032] In the above examples, the polymer material containing polyether blocks is a composite of polyethylene oxide and polyether ester acetamide in a weight ratio of 5:1.

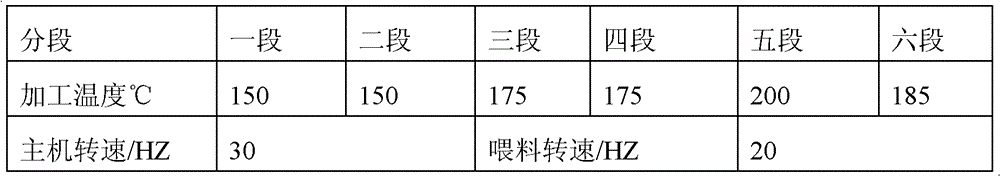

[0033] Put the above components into a high mixer according to the proportion and mix them for 2-5 minutes, discharge the material, and then use a screw extruder to extrude and granulate. Th...

Embodiment 5

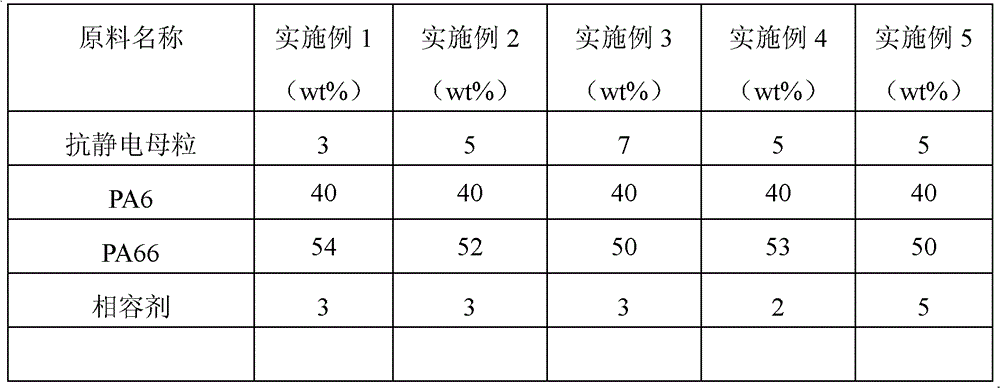

[0039] Example 5 has the lowest surface resistivity and the highest cost performance.

Embodiment 6

[0054] Weigh the raw materials according to the weight ratio: 1% of the above-mentioned antistatic masterbatch, PA640%, PA6658%, 1% compatibilizer, weigh the raw materials according to the weight ratio and put them in a high-mixer for 2-5 minutes and mix them out. The material is then extruded and granulated with a twin-screw extruder, the processing temperature is 235-265°C, and the screw speed is 35-40HZ. The surface resistivity of the prepared material is 10 14 Ω.m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com