Permanent antistatic master batch, permanent antistatic PA66/PA6/PP (Polyamide 66/Polyamide 6/Polypropylene) alloy and preparation method thereof

A technology of antistatic masterbatch and auxiliary antistatic agent, which is applied in the field of alloy materials and antistatic masterbatch, which can solve the problems of low conductivity and achieve the effects of low cost, small amount of addition and high comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

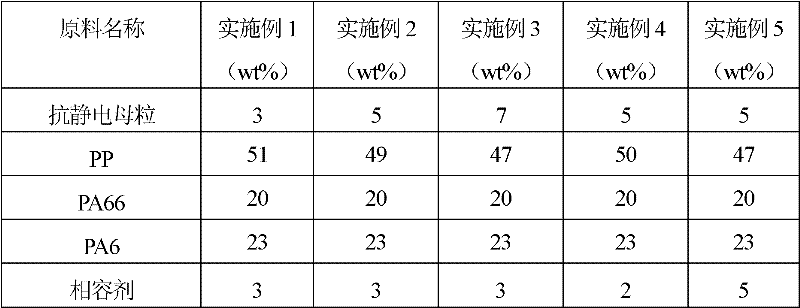

Embodiment 1-5

[0027] Embodiment 1-5 A kind of permanent antistatic masterbatch and preparation method

Embodiment 1

[0029] The composition ratio of the antistatic masterbatch is shown in Table 1. Alkali metal is LiClO 4 , the antioxidant is a compound of phenothiazine and phosphite (s9228) in a mass ratio of 1:1, and the heat stabilizer is an organotin heat stabilizer, calcium stearate, zinc stearate in a mass ratio of 2:1:1 The ratio of the compound, the auxiliary antistatic agent is silicon dioxide, and the polymer material containing polyether block is the compound of polyethylene oxide and polyether ester acetamide in a mass ratio of 5:1.

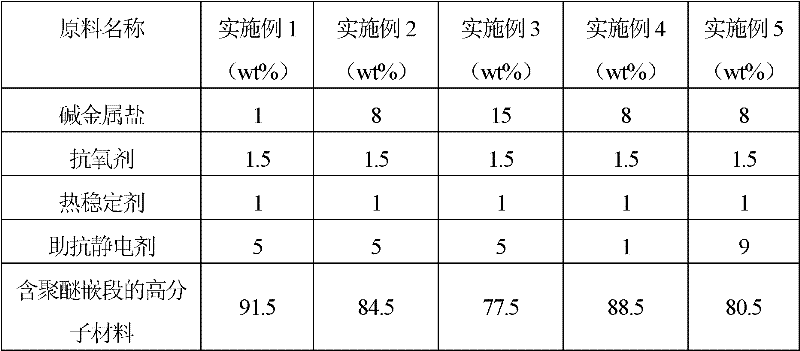

[0030] The antistatic masterbatch raw material formula of table 1 embodiment 1-5

[0031]

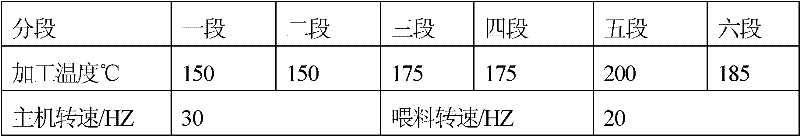

[0032] Put the above components into a high mixer according to the proportion and mix them for 2-5 minutes, discharge the material, and then use a screw extruder to extrude and granulate. The processing temperature is 150-200°C, and the screw speed is 25-35HZ. The specific process is shown in Table 2.

[0033] Table 2 Processing parameters of antistatic ...

Embodiment 2

[0040] The composition ratio of the antistatic masterbatch is shown in Table 1. The alkali metal is LiCl, the antioxidant is a compound of phenothiazine and phosphite (s9228) in a mass ratio of 1:1.5, and the heat stabilizer is an organotin heat stabilizer, calcium stearate, zinc stearate according to 2: A compound with a mass ratio of 1:0.8, the auxiliary antistatic agent is silicon dioxide, and the polymer material containing polyether blocks is a compound of polyethylene oxide and polyether ester acetamide in a mass ratio of 5:1.

[0041] The components were mixed in a high mixer for 8 minutes. The processing parameters are shown in Table 2, and the surface resistivity test data of the obtained antistatic masterbatch are shown in Table 3. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com