Polyurethane spray-coating composite material for storage tank thermal insulation and preparation method thereof

A technology for polyurethane and storage tanks is applied in the field of polyurethane spraying composite materials for thermal insulation of storage tanks and the field of preparation thereof, which can solve the problems of poor stability of polyurethane foam, affect the physical properties of foam, and low flame retardant effect, and achieve low cost and product quality. Stable, short production cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

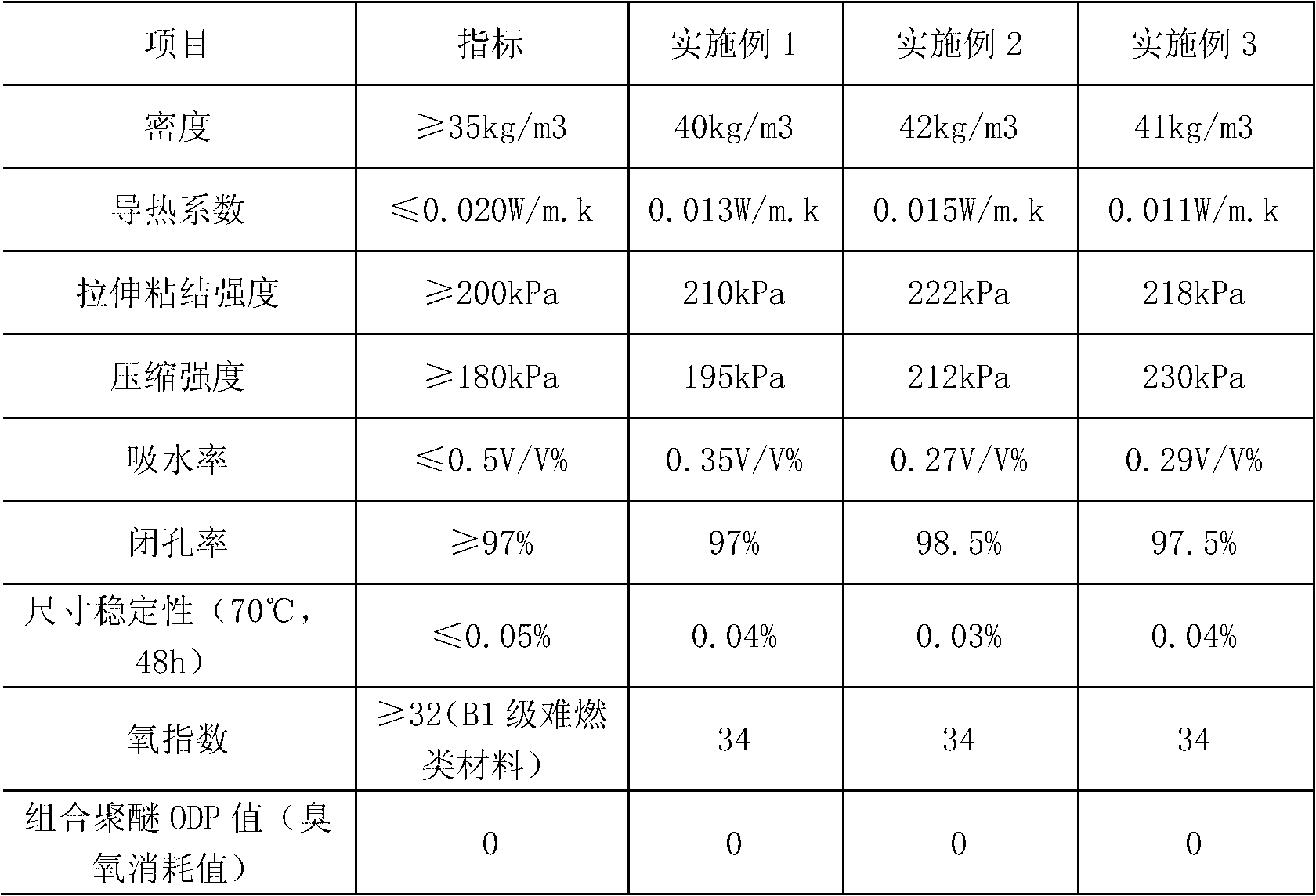

Examples

Embodiment 1

[0028] 1. Prepare component A, 200kg: Weigh polyether polyol A: B251 (Solvay), 76kg, polyether polyol B, 20kg, polyester polyol: 6320LA (Nanjing Kangsude), 17kg, Foam stabilizer B-8538 (Evonik), 3kg, deionized water, 1.1kg, catalyst selection N,N,N',N",N"-pentamethyldiethylenetriamine, triethylenediamine , 1,3,5-tris(dimethylaminopropyl)-hexahydrotriazine and dibutyltin dilaurate, the weights are 1.5kg, 1.2kg and 0.2kg respectively, physical blowing agent HFC-365mfc / normal Pentane (a mixture of HFC-365mfc and n-pentane, the weight ratio of the two is 29:21), 40kg, flame retardant TCPP, 36kg, other additives, 4kg.

[0029] Add the weighed polyether polyol A, polyether polyol B, polyester polyol, foam stabilizer, chemical foaming agent, catalyst, flame retardant, physical foaming agent and other additives into the reactor in sequence , stirred at room temperature for 0.5 hours, and mixed thoroughly.

[0030] 2. Component B polymerized diphenylmethane diisocyanate, 200kg.

[0...

Embodiment 2

[0033] 1. Prepare component A, 200kg: Weigh polyether polyol A: B251 (Solvay), 60kg, polyether polyol B, 36kg, polyester polyol: 6320LA (Nanjing Kangsude), 20kg, Foam stabilizer B-8538 (Evonik), 3kg, deionized water, 2kg, catalyst selection N,N,N',N",N"-pentamethyldiethylenetriamine, triethylenediamine, Mixture of 1,3,5-tris(dimethylaminopropyl)-hexahydrotriazine and dibutyltin dilaurate, weighing 1.6kg, 1.0kg and 0.4kg respectively, physical blowing agent HFC-365mfc / n-amyl Alkane (a mixture of HFC-365mfc and n-pentane, the weight ratio of the two is 29:21), 40kg, flame retardant TCPP, 32kg, other additives, 4kg.

[0034] Add the weighed polyether polyol A, polyether polyol B, polyester polyol, foam stabilizer, chemical foaming agent, catalyst, flame retardant, physical foaming agent and other additives into the reactor in sequence , stirred at room temperature for 0.5 hours, and mixed thoroughly.

[0035] 2. Component B polymerized diphenylmethane diisocyanate, 210kg.

[0...

Embodiment 3

[0038] 1. Preparation of component A, 200kg: Weigh polyether polyol A: B251 (Solvay), 75kg, polyether polyol B, 35kg, polyester polyol: 6320LA (Nanjing Kangsude), 20kg, Foam stabilizer B-8538 (Evonik), 3kg, deionized water, 1.8kg, catalyst selection N,N,N',N",N"-pentamethyldiethylenetriamine, triethylenediamine , 1,3,5-tris(dimethylaminopropyl)-hexahydrotriazine and dibutyltin dilaurate, the weights are 1.5kg, 1.3kg and 0.2kg respectively, physical blowing agent HFC-365mfc / normal Pentane (a mixture of HFC-365mfc and n-pentane, the weight ratio of the two is 29:21), 25kg, flame retardant TCPP, 35kg, other additives, 2.2kg.

[0039] Add the weighed polyether polyol A, polyether polyol B, polyester polyol, foam stabilizer, chemical foaming agent, catalyst, flame retardant, physical foaming agent and other additives into the reactor in sequence In, stir at room temperature for 1 hour, mix well.

[0040] 2. Component B polymerized diphenylmethane diisocyanate, 200kg.

[0041] 3. M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com