Water-based altering agent and preparation method thereof

A correction agent, water-based technology, applied in the field of water-based correction agent and its preparation, can solve the problems of unsatisfactory covering power, complex production process, slow drying speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

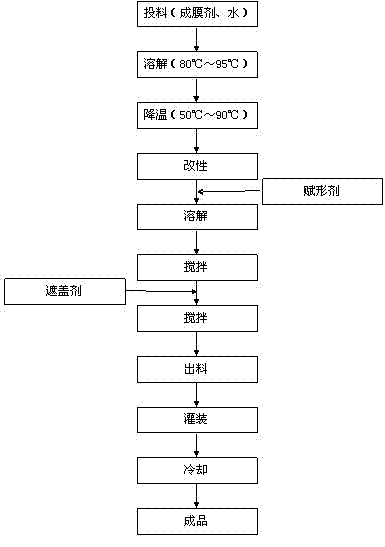

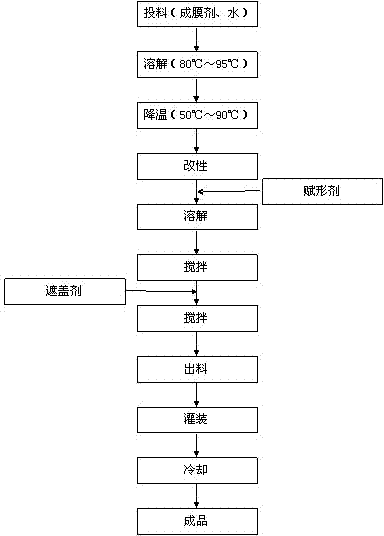

[0045] The preparation method of water-based correction agent comprises the following steps: the following is calculated by weight percentage:

[0046] Step 1. Put 0.1%-3.9% film-forming agent and 30%-70% water into the reaction kettle at one time;

[0047] Step 2, dissolving the raw materials in step 1 completely at 80°C to 95°C;

[0048] Step 3. Lower the temperature to 50°C-90°C. After modification, add 2.5%-15% excipient to dissolve it and stir evenly;

[0049] Step 4, add 10% to 55% of the covering agent, and stir evenly;

[0050] Step 5, discharge, fill in the mold, and obtain the finished product after cooling.

[0051] The weight percentage of the film forming agent is 1.5%-3%, and the weight percentage of water is 48%-60%.

[0052] The melting temperature ranges from 85°C to 90°C.

[0053] The weight percentage of the excipient is 4%-9%; the cooling range in the step 3 is 70°C-85°C; the weight percentage of the covering agent in the step 4 is 30%-40%.

Embodiment 1

[0055] The preparation method of water-based correction agent of the present invention comprises the following steps: following by weight percentage:

[0056] Step 1, 2% of polyvinyl alcohol, polyvinyl formal, polyvinyl furfural and one or more mixtures thereof and 63% of water are thrown into the reactor at one time;

[0057] Step 2, dissolving the raw materials in step 1 completely at 85°C;

[0058] Step 3, then lower the temperature to 70°C, after modification, add 5% of sodium stearate, sodium laurate, sodium palmitate, sodium myristate and agar or a mixture of one or more of them to dissolve , and stir evenly;

[0059] Step 4, add 30% calcium carbonate, calcium sulfate, titanium dioxide and magnesium carbonate, one or more mixtures, and stir evenly;

[0060] Step 5, discharge, fill in the mold, and obtain the finished product after cooling.

Embodiment 2

[0062] The preparation method of water-based correction agent of the present invention comprises the following steps: following by weight percentage:

[0063] Step 1, 3% of polyvinyl alcohol, polyvinyl formal, polyvinyl furfural and one or more mixtures thereof and 48% of water are thrown into the reactor at one time;

[0064] Step 2, dissolving the raw materials in step 1 completely at 85°C;

[0065] Step 3, then lower the temperature to 70°C, after modification, add 9% of sodium stearate, sodium laurate, sodium palmitate, sodium myristate and agar or a mixture of one or more of them to dissolve , and stir evenly;

[0066] Step 4, add 40% of calcium carbonate, calcium sulfate, titanium dioxide and magnesium carbonate, one or more mixtures, and stir evenly;

[0067] Step 5, discharge, fill in the mold, and obtain the finished product after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com