Polycarbonate (PC) composite bridge with corrugated steel webs and construction method for PC composite bridge

A technology of corrugated steel webs and corrugated steel plates, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems affecting the bending and torsional stiffness of double corrugated steel webs, and restrict the competitiveness of double corrugated steel web bridges , increasing costs and other issues, to achieve the effect of beautiful appearance, shortening the construction period, and improving local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

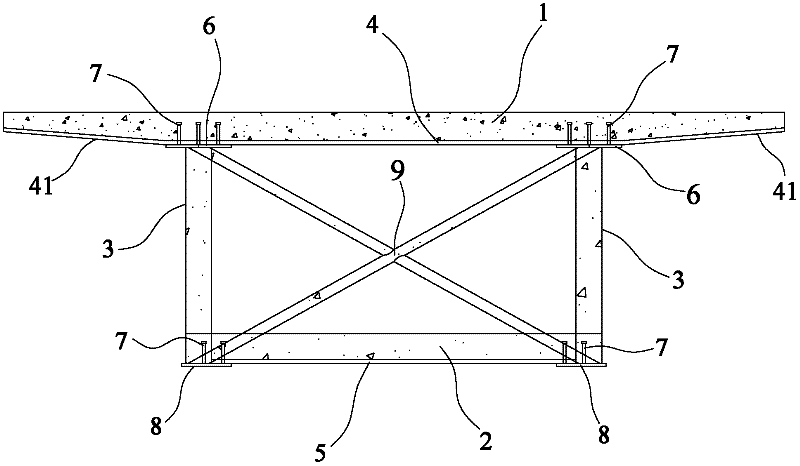

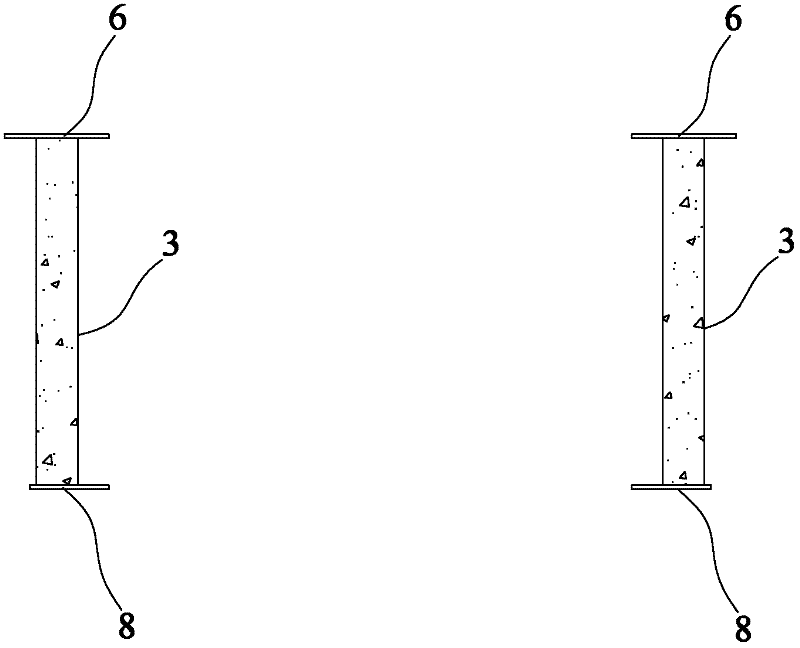

[0042] Please refer to figure 1 and figure 2 As shown, it shows a specific structure of a PC bridge with corrugated steel webs in the present invention, including a concrete roof 1, a concrete floor 2, and two double waveforms that are symmetrically distributed between the concrete roof 1 and the concrete floor 2 Steel web 3, the double corrugated steel web 3 can be erected or obliquely erected, wherein:

[0043] The bottom surface of the concrete roof 1 is equipped with an upper profiled steel plate 4 , and the bottom surface of the concrete bottom plate 2 is equipped with a lower profiled steel plate 5 .

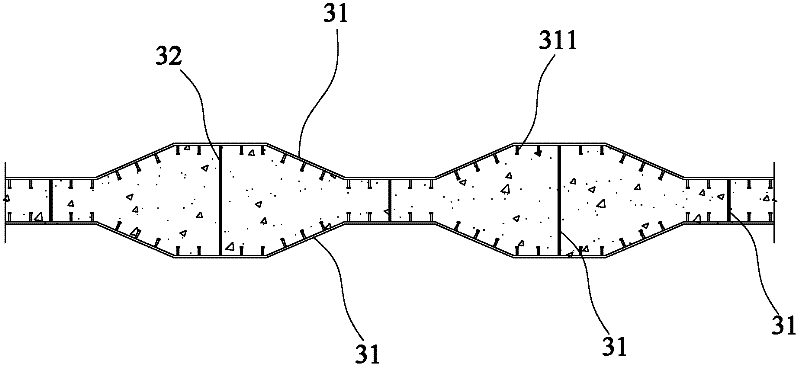

[0044]The double corrugated steel web 3 includes two layers of corrugated steel plates 31 and a plurality of connectors 32 connected between the two layers of corrugated steel plates 31, and the connectors 32 are connected between the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com