Method for comprehensively detecting drilling depth travel of fully hydraulic drilling machine for coal mine

A drilling depth and comprehensive detection technology, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., can solve the problems of cumulative error of oil detection device and oil leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

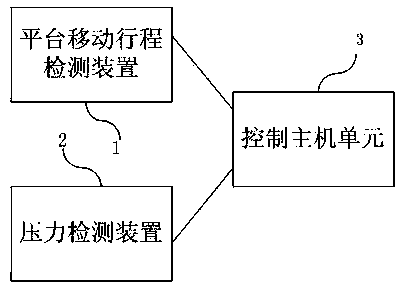

[0025] The method for comprehensively detecting the drilling depth of a fully hydraulic drilling rig for coal mines according to the present invention includes a platform moving stroke detection step, a pressure detection step, and a comprehensive judgment step based on the aforementioned two;

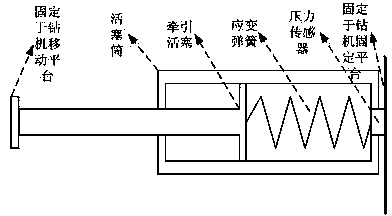

[0026] The moving stroke detection step of the platform is to use sensor technology to detect in real time the reciprocating stroke of the axially driven oil cylinder of the drill rod. When the single-rod double-acting oil cylinder moves to the bottom of the oil cylinder when the piston moves to the bottom of the cylinder, the platform moves to the end of the drill floor, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com