Adjustable impact cylinder

A shock cylinder, adjustable technology, applied in the direction of fluid pressure actuating device, etc., can solve the problems of increased gas pressure, decreased shock frequency, long gas supply time, etc., to improve gas supply speed, low manufacturing cost, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

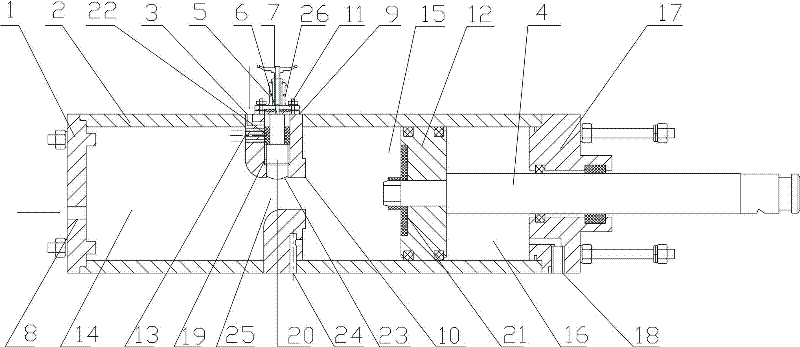

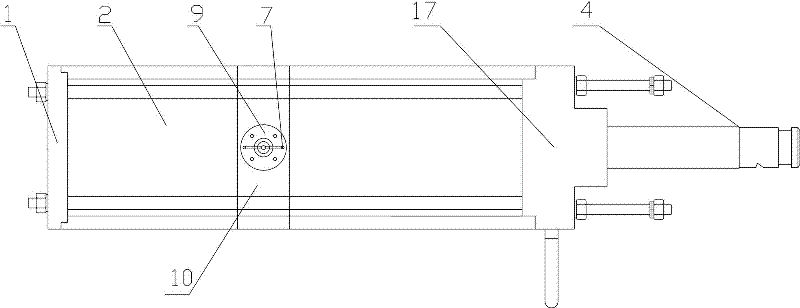

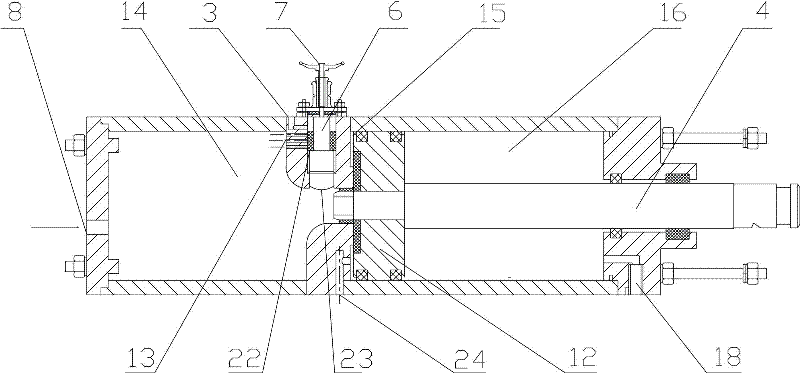

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Adjustable impact cylinder, including cylinder barrel 2, sealing piston 12, front cover 17, rear cover 1 and middle cover 10, middle cover 10 and sealing piston 12 divide the cylinder into air storage chamber 14, rodless chamber 15 and rod chamber 16. A straight-through valve 20 is set on one side of the middle cover 10, and its spool 23 can move up and down on the vertical surface of the cylinder 2 to change the flow area of the spout 25 on the middle cover. The spool 23 is in a region Moving, the distance between the spool 23 and the edge of the nozzle 25 at the top dead center (at this time the flow area of the nozzle reaches the maximum) and the bottom dead center, that is, the maximum extension of the valve core 23, is L. The upper end of the middle cover 10 facing the side of the air storage chamber 14 is sequentially provided with small air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com