Breather valve test bed for improving test efficiency and test method thereof

A technology for testing efficiency and breathing valves, applied in mechanical valve testing, fluid tightness testing, machine/structural parts testing, etc., can solve the problems of low testing accuracy and testing efficiency of marine breathing valves, and improve space utilization , good test accuracy, the effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

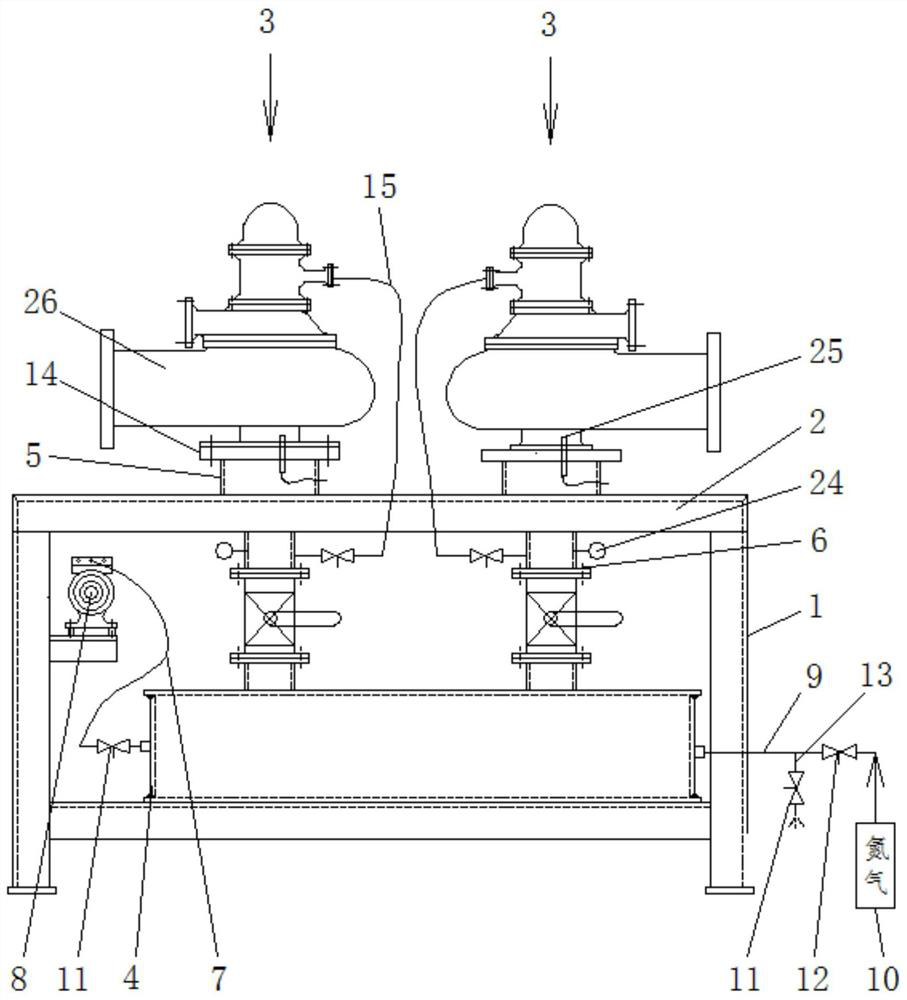

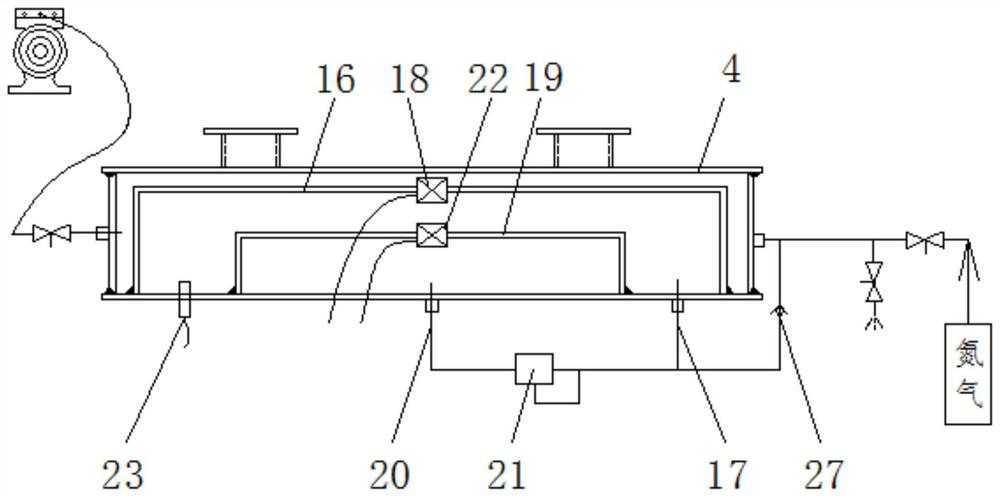

[0031] Such as Figures 1 to 2 Shown is a kind of embodiment that is used for improving the breathing valve test bench of the present invention, comprises frame 1, is arranged on the frame platform 2 of described frame 1 upper end, is arranged on described frame platform 2 A certain number of test stations 3, the gas collection box 4 arranged at the lower part of the frame 1, each of the test stations 3 is provided with a butt pipe 5 for installing a breathing valve 26, and the butt pipe 5 The test pipeline 6 communicates with the inside of the gas collection box 4, the gas collection box 4 is connected to the vacuum device 8 through the vacuum suction pipeline 7, and the gas collection box 4 is connected to the air supply through the air intake pipeline 9 In the unit 10, a ball valve 11 is arranged on the vacuum suction pipeline 7, and a needle valve 12 is arranged on the air intake pipeline 9.

[0032] In this embodiment, the test pipeline 6 is provided with a ball valve 11...

Embodiment 2

[0043] A kind of test method that adopts embodiment 1 to be used to improve the breathing valve test bench of test efficiency, comprises the steps:

[0044] (1) Breathing valve installation: a group of breathing valves 26 are correspondingly installed on the flanges 14 of each docking pipeline 5, and the control air circuit 15 on the test pipeline 6 is connected to the breathing valve 26;

[0045] (2) Positive pressure take-off test: close the ball valve 11 on the vacuum suction pipeline 7, adjust the needle valve 12 on the intake pipeline 9 to a suitable opening, and pass the air supply unit 10 through the gas collection box 4 to the breathing valve 26 is inflated and pressurized, and the ball valve 11 on the test pipeline 6 is opened to keep the pressure uniform rate of rise in the positive pressure test process at about 0.001MPa / s, so as to accurately collect the pressure value of the positive pressure take-off of the breathing valve 26, such as The pressure value deviates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com