Device and method for detecting tension of elliptic sleeve type steel wire rope

A tension detection and wire rope technology, applied in the direction of tension measurement, etc., can solve the problems of destroying the integrity of the wire rope, affecting the mechanical properties, and low detection efficiency, and achieving the effects of wide practicability, convenient operation and high detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

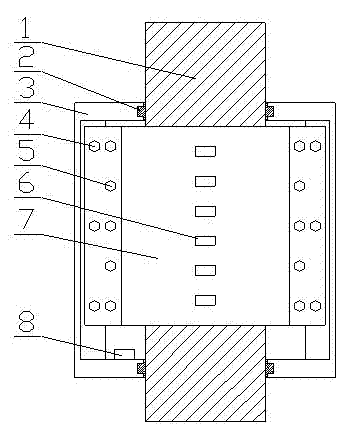

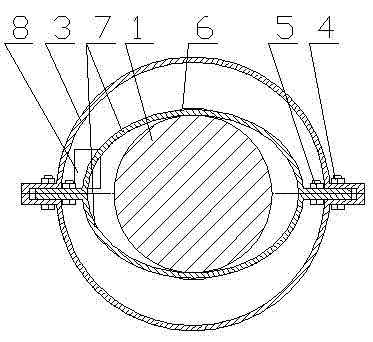

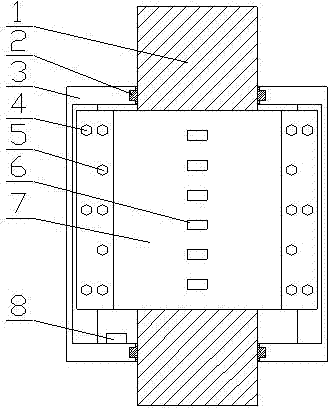

[0019] Such as Figure 1~2 As shown, the elliptical sleeve type steel wire rope tension detection device of the present invention comprises two symmetrically fastened and pressed arc-shaped tension sensing plates 7 on both sides of the steel wire rope 1 with side wings, and the arc-shaped tension sensing plates 7 have a carbon content of 0.5% to 0.8% carbon steel. The side wings of the arc-shaped tension sensing plate 7 are fixedly connected by the internal fastening bolts 5, and the inner walls of the two buckled arc-shaped tension sensing plates 7 form an elliptical cylinder, and the length of the minor axis of the elliptical cylinder is 90% of the diameter of the steel wire rope 1 ~95%, the length of the major axis of the oval cylinder is 140%~150% of the diameter of the steel wire rope 1. 6-10 resistance strain gauges 6 are pasted along the central ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com