Heat dissipation module of compact disc read-only memory driver core in auto sound

A car audio and heat dissipation module technology, applied in the electrical field, can solve the problems of large heat generation, slow internal air flow, and increased working temperature of the optical disc movement, and achieve the effect of promoting heat insulation and meeting the requirements of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

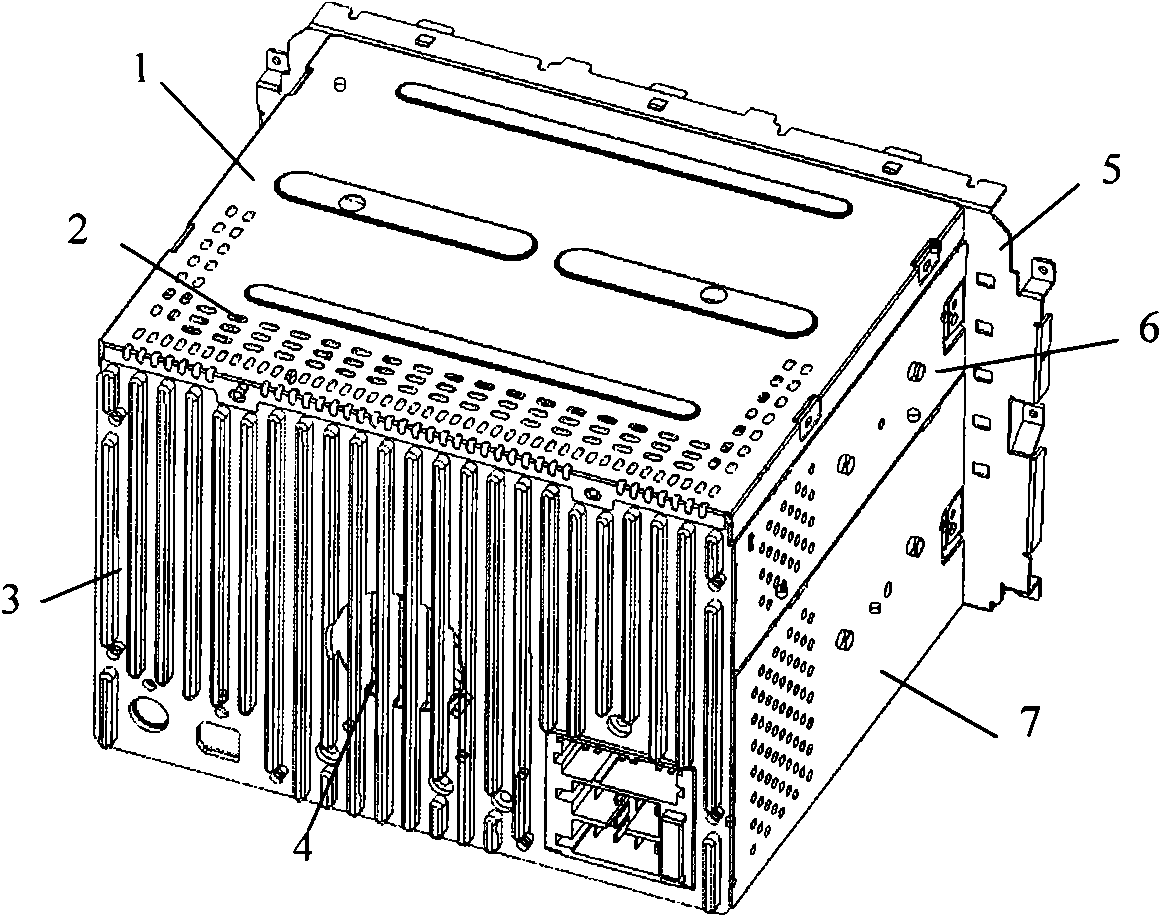

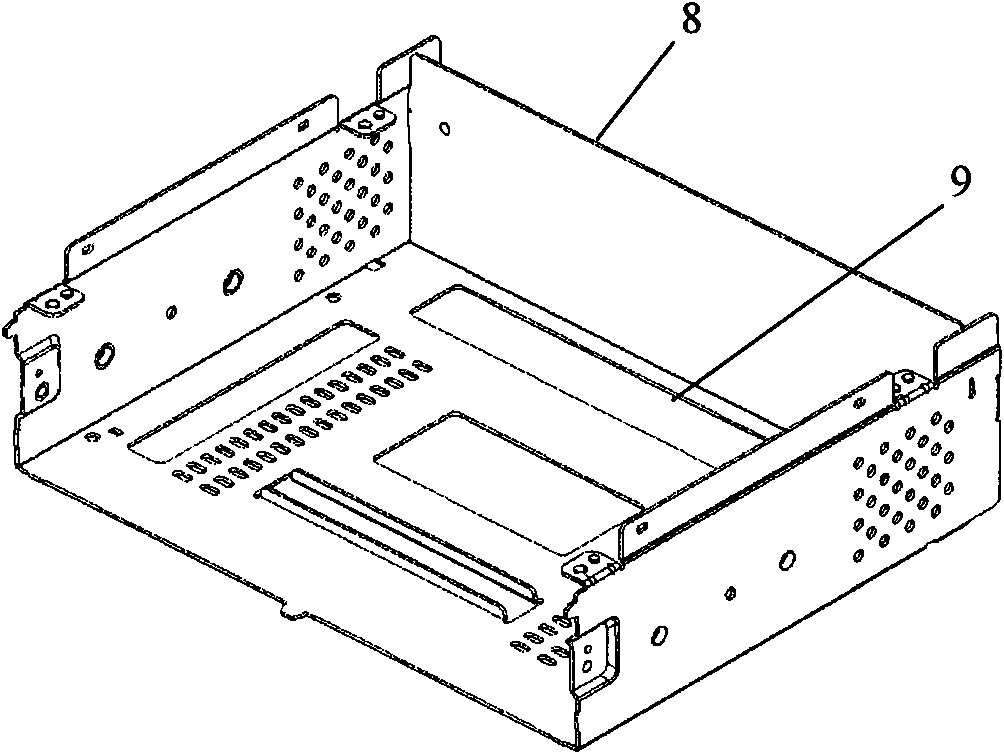

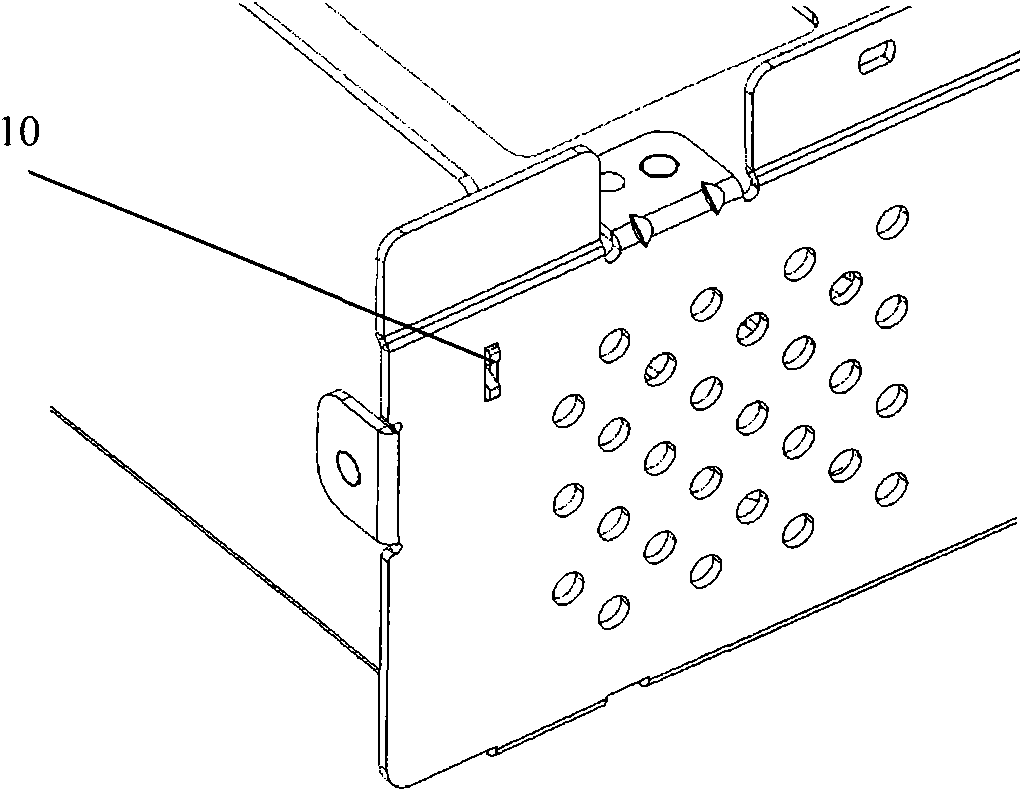

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the heat dissipation module of a car audio optical disc drive core of the present invention is composed of an audio chassis, and the audio chassis includes an upper cover 1, a radiator 3, a front cover 5, an upper casing 6 and a lower casing 7. The upper casing 6 is arranged above the lower casing 7, wherein the front cover 5 is connected to the front sides of the upper casing 6 and the lower casing 7, and the radiator 3 is connected to the upper The housing 6 and the rear side of the lower housing 7, the upper cover plate 1 is connected to the upper side of the upper housing 6, the radiator 3 is provided with a fan outlet 4, and the upper cover plate 1 is provided with a ventilation hole 2 , The upper housing 6 is provided with a bottom plate, and the bottom plate is provided with a vent 9 which communicates with the inner cavity of the lower housing 7, and a heat insulation baffle 8 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com