Liquid-cooled battery tray and battery box

A battery tray, liquid cooling technology, applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of poor cooling effect and heavy tray weight, avoid load-bearing deformation, reduce energy loss, and achieve good cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

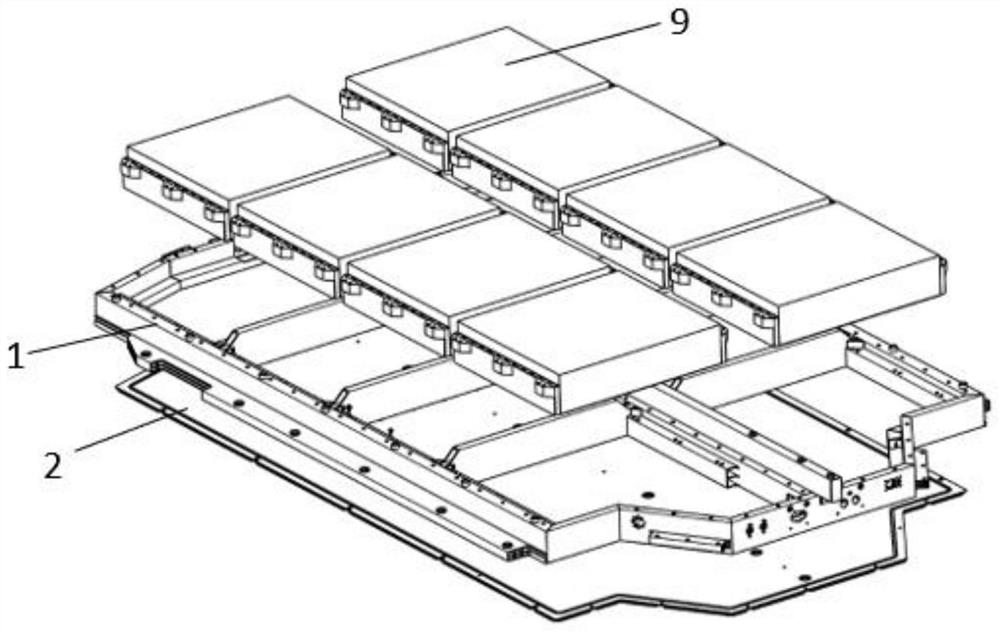

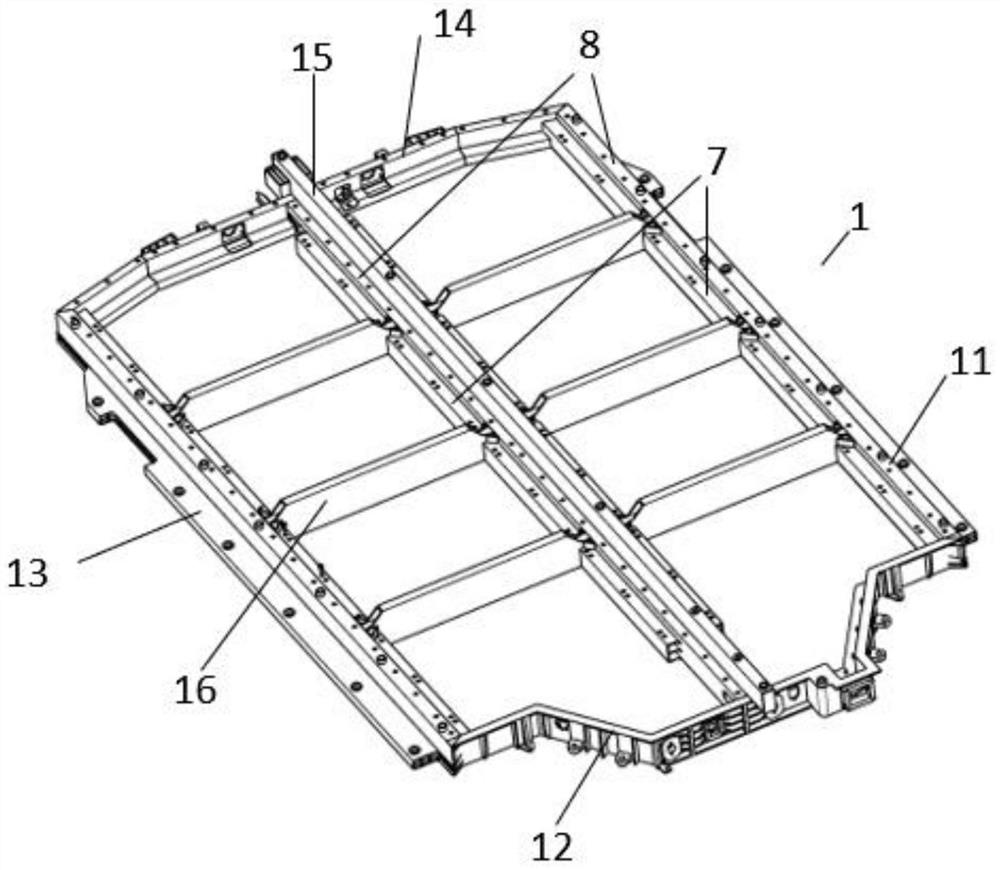

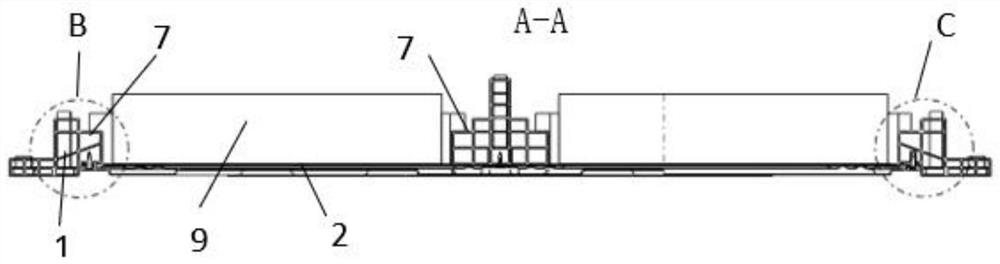

[0030] The battery box is the bearing and protection mechanism of the battery module. Multiple battery modules are installed on the battery tray in the battery box. The battery module is composed of multiple batteries connected in series or in parallel. A liquid cooling plate assembly for maintaining the temperature inside the battery pack is also provided. Such as Figure 1-6 As shown, the liquid-cooled battery tray in the embodiment of the present application includes a tray frame 1 and a liquid-cooled plate assembly 2. The tray frame 1 is provided with a module installation surface 7 for cooperating with the battery module 9, and the battery module 9 passes through the mold. The group mounting surface 7 is fixed on the tray frame 1; the liquid cooling plate assembly 2 includes a liquid cooling plate 21 and a protective plate 22; the liquid cooling plate 21 is fixed under the tray frame 1, and the liquid cooling plate 21 is in contact with the bottom of the battery module 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com