BIPV layered hollow glass curtain wall structure

A glass curtain wall and hollow technology, applied to walls, building components, building structures, etc., can solve problems such as life impact, and achieve the effects of prolonging service life, reducing energy loss, and lowering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

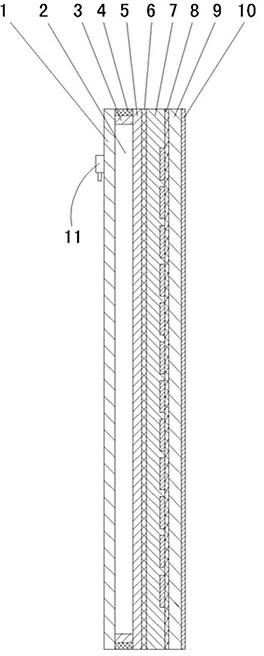

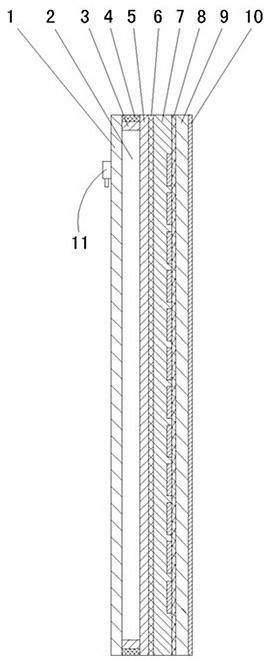

[0008] Such as figure 1 Shown: 9 is the front glass, 1 is the rear glass, and the front EVA layer 8, the photovoltaic solar cell layer 7, the rear EVA layer 6, and the TPT layer 5 are successively arranged between the front glass 9 and the rear glass 1. Made by lamination. There is an aluminum alloy spacer 3 on the periphery between the TPT layer 5 and the rear glass 1, and glue is poured on the outside of the spacer 3 to form a rubber strip 4 for sealing. A space interlayer 2 is formed in the middle between the TPT layer 5 and the back glass 1 . Space interlayer 2 is filled with inert gas. A junction box 11 connected to the photovoltaic solar cell layer 7 by wires is arranged behind the rear glass 1 . There is a fixed clamping frame of aluminum alloy material at the periphery between the front glass 9 and the rear glass 1, so that each layer forms a whole. A filter film 10 that can pass through 0.4-1.1 μm sunlight is pasted on the front of the front glass 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com