Flywheel battery

A flywheel battery and flywheel technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of inability to achieve long-term effective storage of kinetic energy, infeasible mechanical bearings, slow charging and discharging speed, etc., to facilitate mass production and maintenance. The effect of maintenance, extended service life, and increased charging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

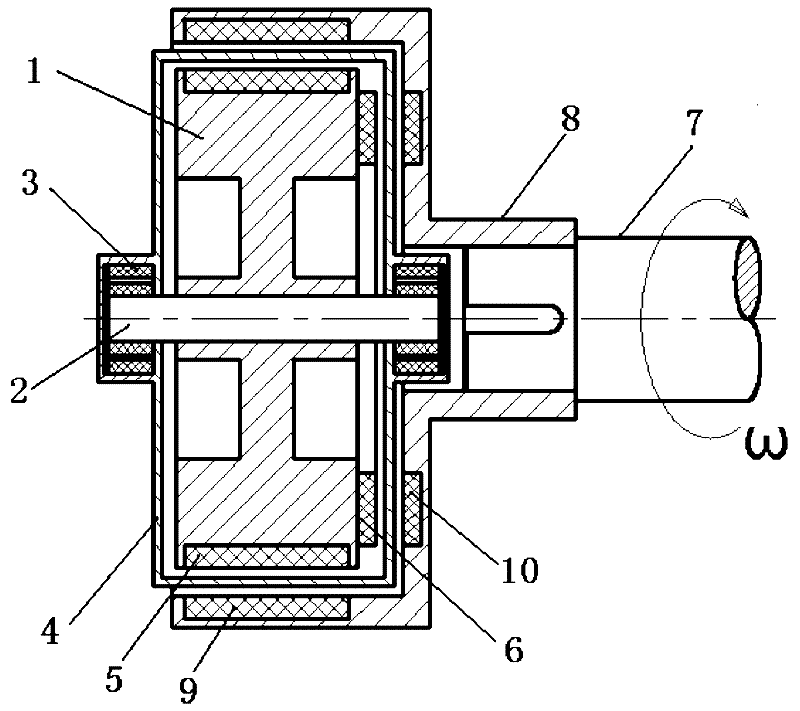

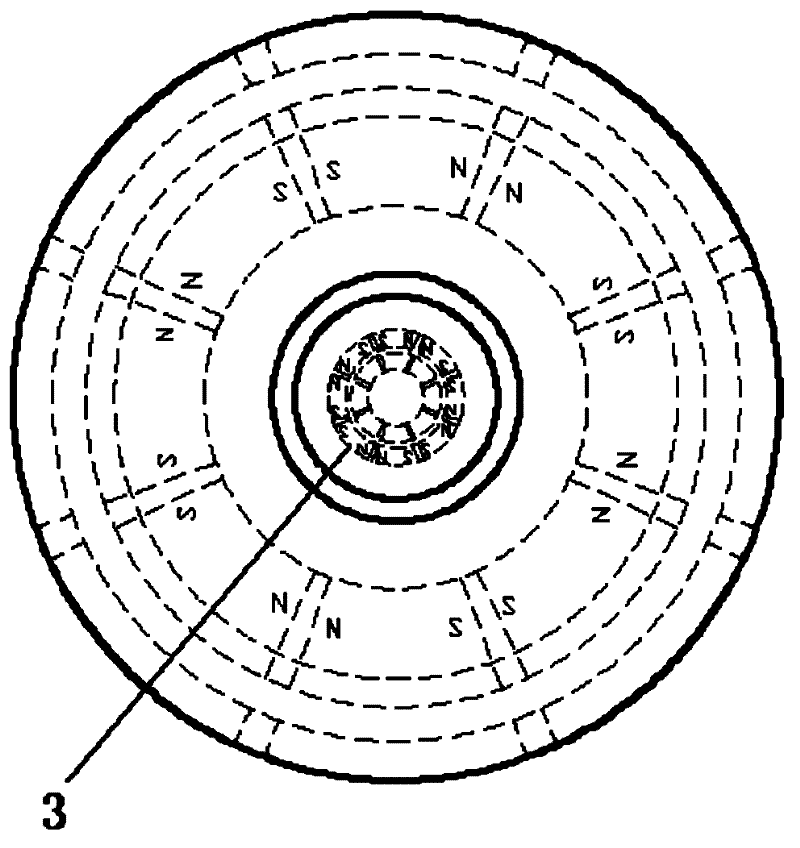

[0028] A kind of flywheel battery, such as figure 1 As shown, it includes a flywheel device and a drive device for driving the flywheel to rotate. The flywheel device includes a flywheel 1, a flywheel shaft 2, a flywheel shaft 2 with a magnetic suspension bearing 3 for supporting the flywheel shaft 2. The magnetic poles are NNSS arranged in pairs. Such as figure 2 As shown, the flywheel device further includes a vacuum enclosure 4 provided on the periphery, and the vacuum enclosure 4 is a closed thin-walled cavity made of non-magnetic material with an annular cross section. The vacuum sealing cover 4 is in interference fit with the magnetic suspension bearing 3, and the flywheel 1 is made of magnetic material or an inner magnet is fixed on the outer side of the circumferential surface of the flywheel 1. Since the flywheel 1 is directly made of magnetic material, the cost is relatively high. Therefore, in this embodiment, an axial inner magnet 5 and a radial inner magnet 6 are ...

Embodiment 2

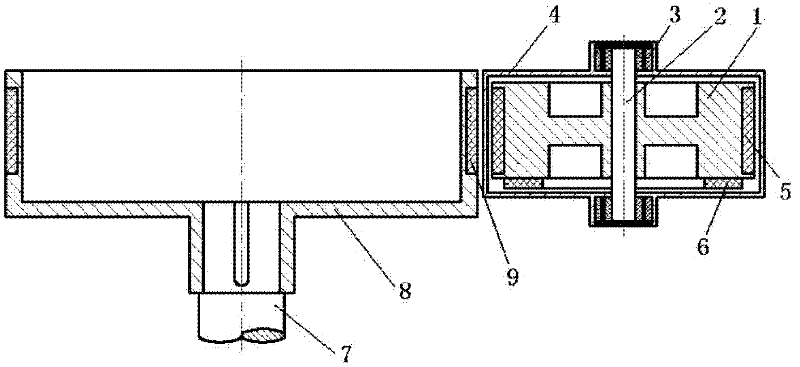

[0034] The structure of the driving device and the flywheel device in the second embodiment is similar to that in the first embodiment. The difference is that the installation positions of the driving device and the flywheel device are different, such as image 3 As shown, the flywheel device is arranged outside the circular sleeve of the rotor 8, the axis of the flywheel shaft 2 is parallel to the axis of the rotor 8, and the gap between the vacuum enclosure 4 of the flywheel device and the rotor 8 is 5 mm. The fixed structure in which the driving device and the flywheel device are arranged in parallel is an existing conventional fixing method, which is not covered by the protection scope of the present invention, so it will not be repeated.

[0035] At the same time, since the driving device and the flywheel device are arranged side by side, only the axial outer magnets 9 of the rotor 8 are parallel to the axial inner magnets of the flywheel 1, so in this embodiment, there is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com