Winding die and preparation method for amorphous alloy stator core

A technology of amorphous alloy and stator core, which is applied in the field of stator core preparation technology, can solve the problems of high cost and waste of raw materials, and achieve the effects of avoiding waste, promoting application and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

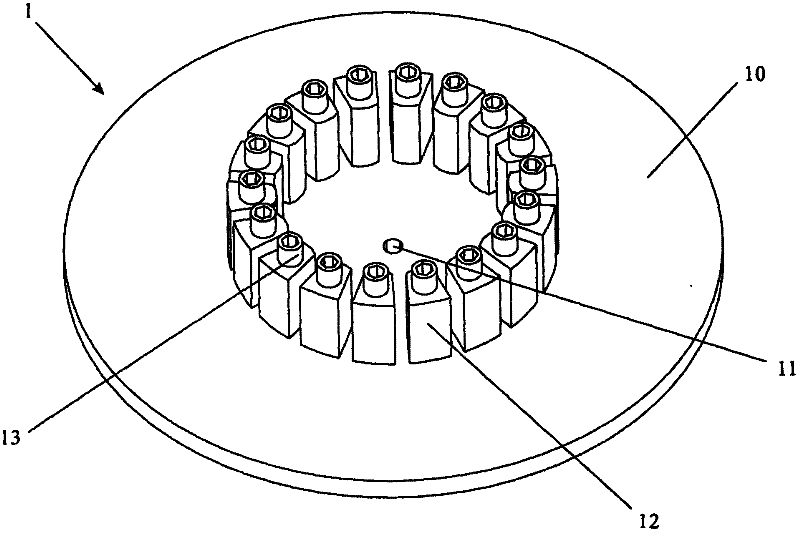

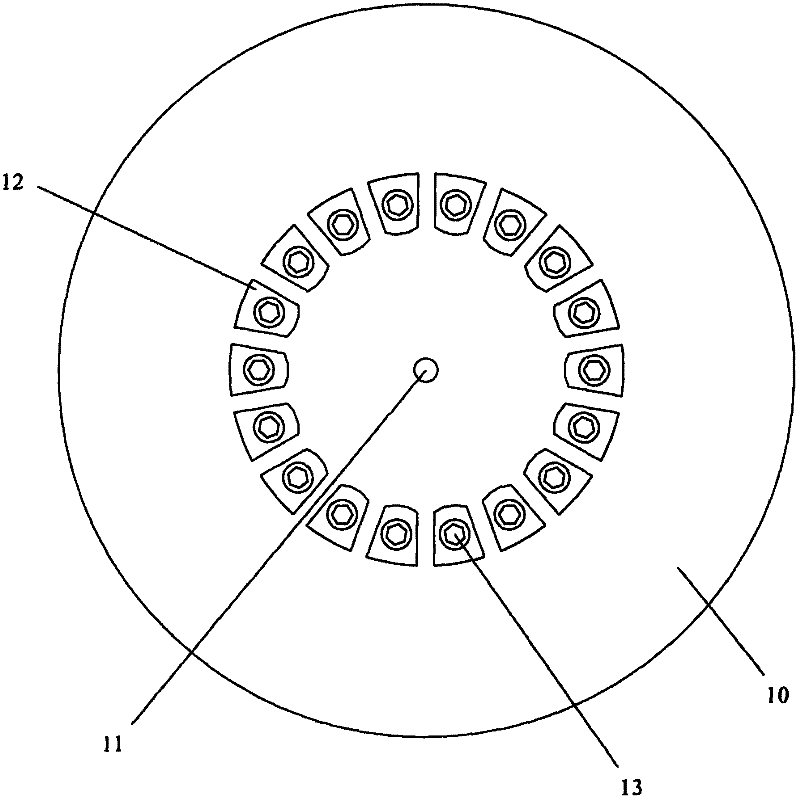

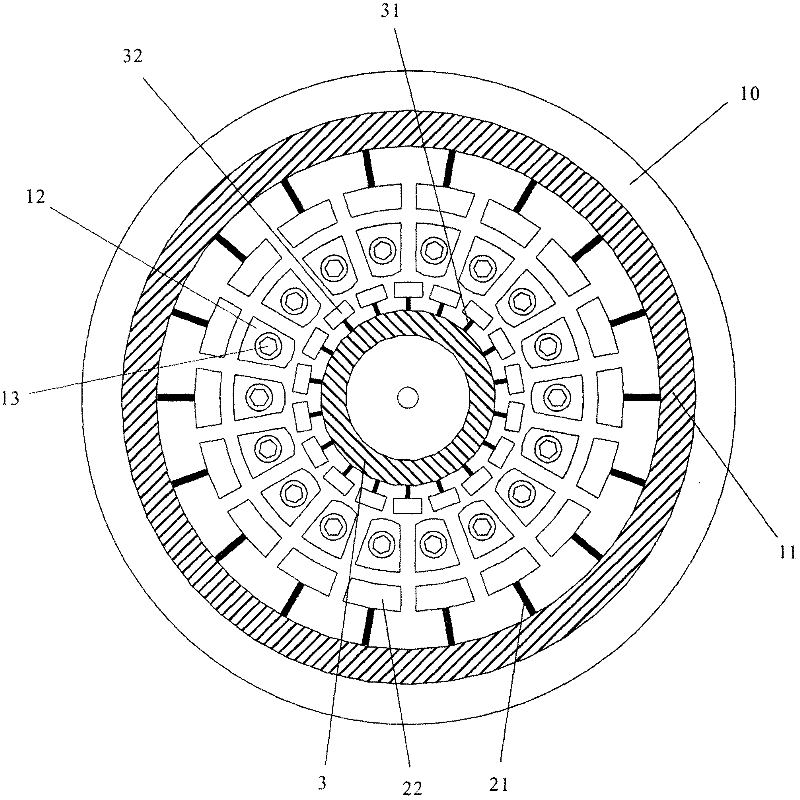

[0039] Please also refer to Figure 1 to Figure 4 , as shown in the figure, the winding mold of the amorphous alloy stator core includes a base mold for winding and a clamping mold matched with the base mold. The base mold 1 further includes a base 10, and the center of the base is opened There are concentric holes 11, and 1 to N central winding shafts 12 are installed on the base, where N>1, and the central winding shafts are fixed on the base by bolts; the central winding shafts surround the concentric holes and are evenly arranged as a The center of the ring is arranged concentrically with the concentric hole, and there is a gap between two adjacent center winding shafts, so there are also 1 to N gaps; the gap between the outer walls of two adjacent center winding shafts is the outer opening of the gap; The gap between the inner sidewalls of two adjacent central winding shafts is the gap inner opening; the clamping mold further includes an outer clamping mold 2 and an inner...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap