Horn shock absorber

A technology of shock absorbers and horns, applied in the direction of sensors, sensor parts, electrical components, etc., can solve the problems of increasing product costs, affecting production efficiency and product quality, so as to improve product quality, reduce the probability of resonance, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through specific embodiments and related drawings.

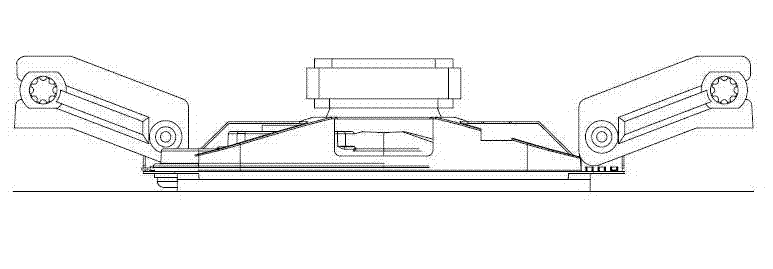

[0015] A horn shock absorber, comprising a primary shock absorbing cushion, a bracket, a secondary shock absorbing cushion and fasteners, wherein the primary shock absorbing cushion is fixed on the shock absorber bracket through the fasteners, The secondary shock-absorbing cushion is buckled in the bracket. Wherein, the first-level shock-absorbing cushion and the second-level shock-absorbing cushion are any one of rubber, silica gel, sponge, EVA, CR, shock-absorbing cotton, EPS, EPE cushioning materials, and the material of the bracket is plastic, metal, For wood, the fastening methods of the fasteners include adhesive fastening, hook fastening, and screw lock fastening, but are not limited thereto.

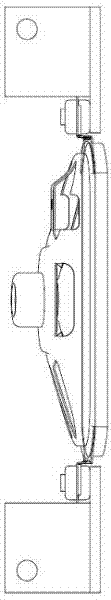

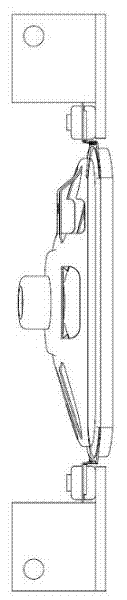

[0016] see figure 1 As shown, it is a diagram of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com