Combined holding device for electric vehicles

A technology for retaining devices and electric vehicles, applied to shafts and bearings, bearing cooling, bearing components, etc., can solve problems such as general cage heat dissipation performance, cage burns, fractures, etc., to reduce temperature, avoid excessive wear, and avoid bias moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

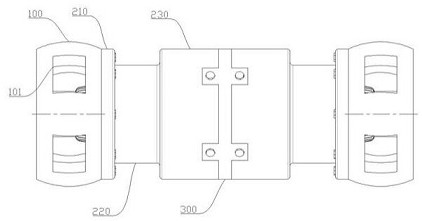

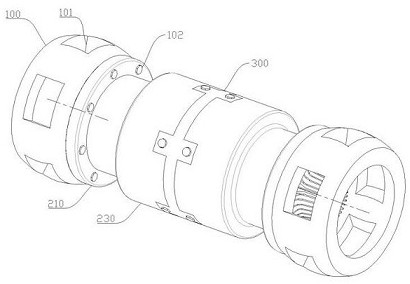

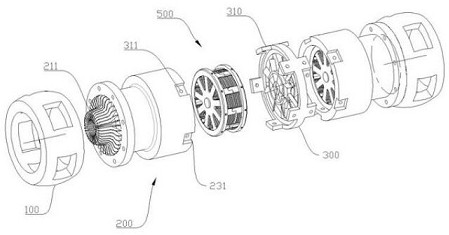

[0037] Such as figure 1 , 2 As shown in , 3, the combined holding device for electric vehicles includes two oppositely placed cages 100, steel ball grooves 101 are evenly arranged around the cages 100, mounting holes 102 are arranged around the opposite sides of the cage 100, and the cage 100 A mounting hole 102 is opened, and a first connector 200 is connected to the opposite side of the cage 100. The first connector 200 includes a first base body 210. The first base body 210 is an annular structure. Corresponding to the hole body, the opposite side of the first base body 210 is fixedly connected to the first ring body 220, the first ring body 220 is coaxially arranged with the first base body 210, and the opposite side of the first ring body 220 is fixedly connected to the tubular first ring sleeve 230, the first Engaging grooves 231 are formed around opposite side edges of the collar 230 .

[0038] In the present invention, through the design of the first base body 210 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com