Combustor

A burner, diffusion combustion technology, applied in burners, combustion chambers, combustion methods, etc., can solve the problems of increased NOx production, complicated rotating parts, increased weight and cost, etc., to suppress stripping, realize NOx, shaft Toward the effect of compact length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

[0044] Next, embodiments of the present invention will be described with reference to the drawings.

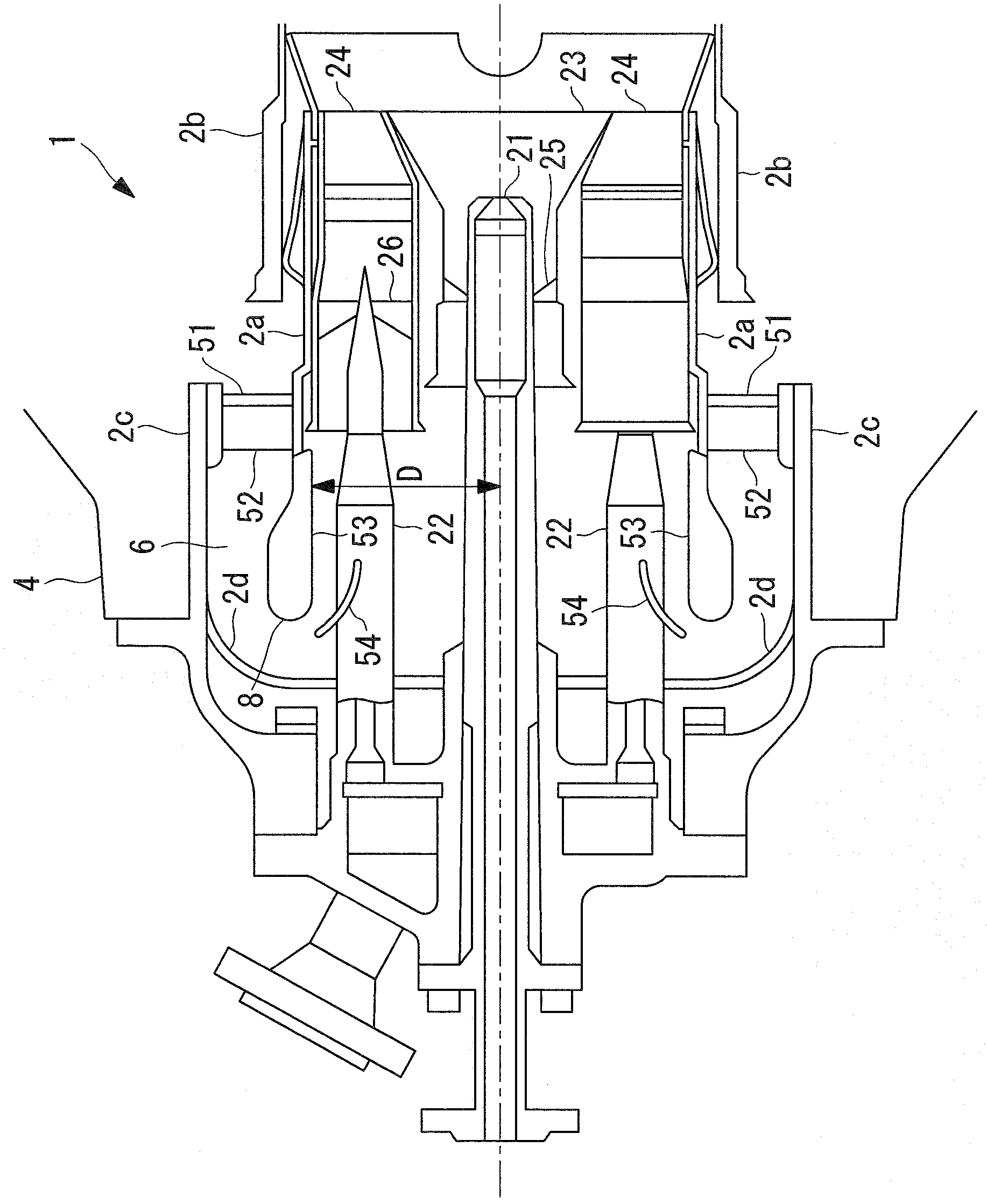

[0045] First, use figure 1 , the burner of the first embodiment will be described. Such as figure 1 As shown, the combustor 1 in this embodiment includes: a pilot nozzle 21 provided along its axis and performing diffusion combustion; The main nozzle 22 of premixed combustion; The guide cone 23 arranged in the mode of covering the front end side of the pilot nozzle 21; The main burner 24 arranged in the mode of covering the front end side of the main nozzle 22; The pilot swirler 25 arranged between the inner walls of the cone 23 ; the main swirler 26 arranged between the outer wall of the main nozzle 22 and the inner wall of the main burner 24 .

[0046] And, the figure 1 The combustor shown is provided with: an inner tube 2a formed substantially coaxially with the pilot nozzle 21 and integrally covering the pilot nozzle 21 and the main nozzle 22; Transition tube 2b that g...

no. 2 approach 〕

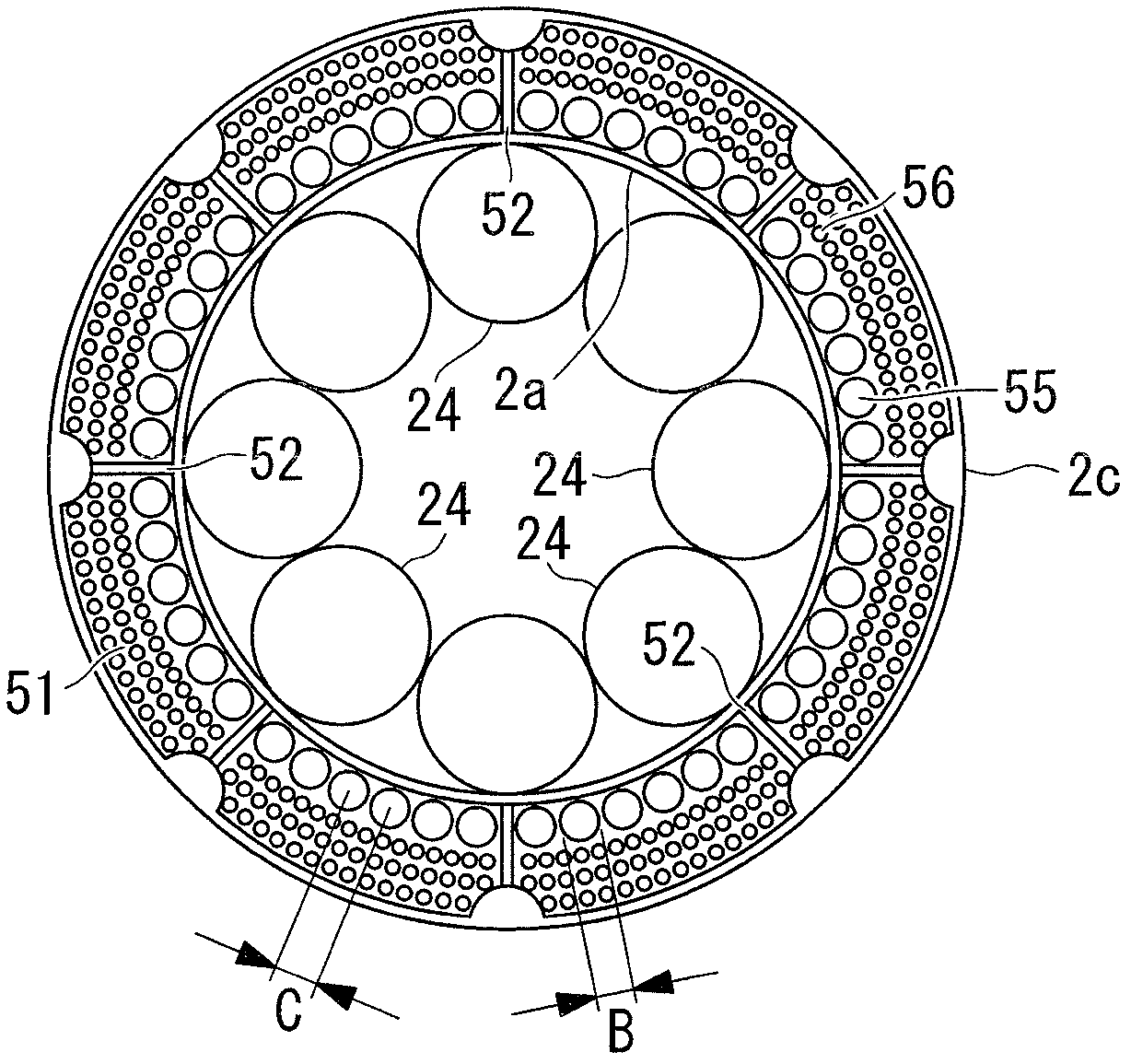

[0072] Next, a second embodiment of the present invention will be described. In addition, the overall structure is the same as that of the said 1st Embodiment, The same code|symbol is used for the same structure, and the description is abbreviate|omitted.

[0073] Figure 5 A partial front view of the rectifying plate 152 of this embodiment is shown in . The rectifying plate 152 of this embodiment is annular, and an outer slit 153 is formed along the outer peripheral edge as a gap with the outer cylinder 2, and an inner slit is formed along the inner peripheral edge as a gap with the inner cylinder 2a. 154. The outer slit 153 and the inner slit 154 are flow passages penetrating the rectifying plate 152 along the axial direction of the flow passage. In addition, rib vicinity slits 155 are respectively provided on the left and right sides of the rib 52 . The rib-near slit 155 is a flow path that penetrates the straightening plate 152 in the axial direction of the flow path, ...

no. 3 approach 〕

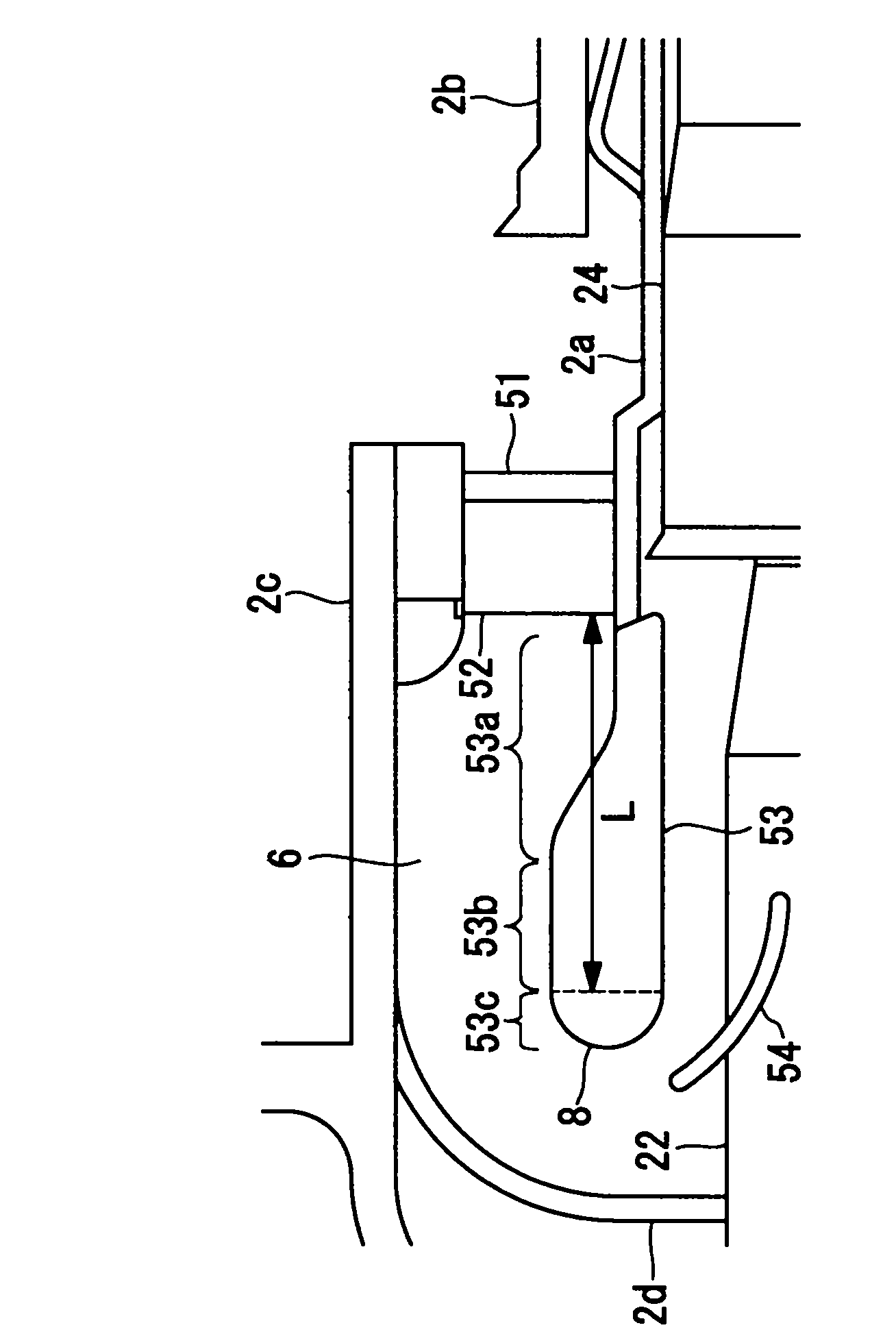

[0079] Next, a third embodiment of the present invention will be described. In addition, the overall structure is the same as that of the said 1st Embodiment, The same code|symbol is used for the same structure, and the description is abbreviate|omitted.

[0080] Such as Figure 7 As shown, the top hat nozzle 160 is positioned halfway through a 180 degree turn. The top hat nozzle 160 is a fuel nozzle for premixed combustion in which the top hat fuel gas and compressed air are mixed and combusted on the upstream side compared with the main nozzle 22 for the purpose of reducing NOx. 22 is provided with multiple near the outer peripheral side.

[0081] The inner peripheral portion of the 180-degree turn portion 8 partially has a circular shape in the cross-sectional shape of the burner along the axis as shown in the figure, so that the flow path smoothly changes direction by 180 degrees. The top hat nozzle 160 is a cylinder with a diameter of 10 mm in this embodiment, and is a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap