Multifunctional urban road cleaning vehicle

A multifunctional, cleaning vehicle technology, applied in road cleaning, snow cleaning, construction, etc., can solve the problems of single function, complex structure, expensive price, etc., and achieve the effect of simple and flexible operation, simple and reasonable structure, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

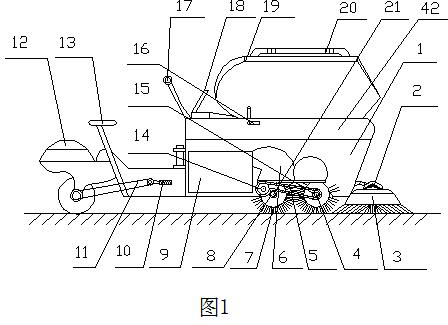

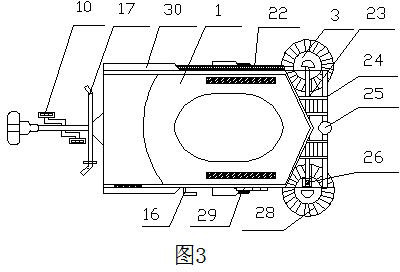

[0019] Depend on Figure 1-4 As shown, 1 in the figure is the front car body of the car body, the front car body 1 includes a cleaning mechanism, a walking mechanism, and a garbage collection mechanism, and the rear car body includes a battery 38, a seat and a human walking mechanism;

[0020] The cleaning mechanism includes: a front brush frame 24 hinged with the front end of the front vehicle body 1 and a rotating body 3 with a cleaning brush, a balance beam 23 is provided on the front brush frame 24, and the lower parts of the two ends of the balance beam 23 pass through the bevel gears 2 respectively. A rotating body support base 31 is hinged, and the rotating body 3 with a cleaning brush is fixed on the lower part of the rotating body support base 31; a clutch 26 is provided on the balance beam 23, and the flywheel 43 of the clutch 26 travels with the front vehicle body through the chain 44 The speed increasing sprocket 27 on the main shaft 47 of the wheel 29 is connected...

example 2

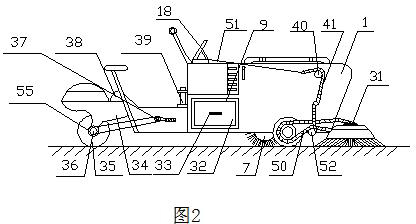

[0031] like Figure 5 As shown, the snow removal mechanism includes a snow removal frame 102 that is hinged with the front end of the front vehicle body 1, a snow removal board 101 is provided at the front end of the snow removal frame 102, and a snow removal frame hinge 103 is provided at the rear end of the snow removal frame 102. The frame 102 is provided with a hinge hole 104 connected with the chain 41 .

[0032] In the case of stacking work, or when it snows and freezes in winter, the front brush holder 24 is removed from the front vehicle body 1, and then the hinge part 103 of the snow removal frame is connected to the front vehicle at the hinge part 49 at the front end of the front vehicle body 1. At the same time, push the front brush holder lifting push rod 18 on the front vehicle body, the front end of the front brush holder lifting push rod 18 is connected with the hinged part 103 of the snow board through the pull wire 51, the chain 41 and the guide wheel 40. Art...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com