Elastic coupling

A technology of elastic coupling and semi-coupling, applied in the direction of elastic coupling, coupling, mechanical equipment, etc., can solve the problems of easy damage, poor cushioning effect, high cost, etc., and achieve the effect of absorbing shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

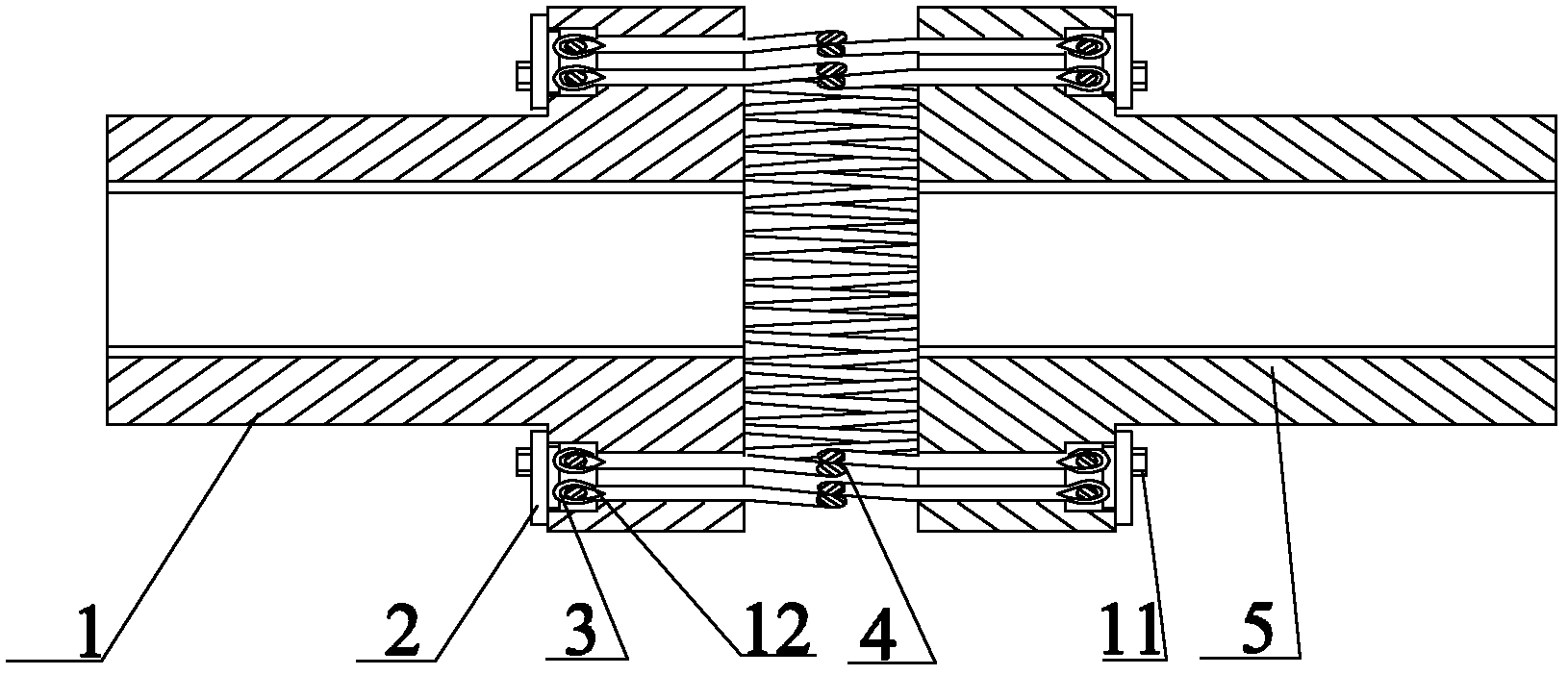

[0023] The present invention proposes an elastic coupling, which includes a first half coupling, a second half coupling and an elastic component, wherein one end of the elastic component is fixedly connected to the first half coupling, and the other end is connected to the second half coupling. The shaft is fixedly connected.

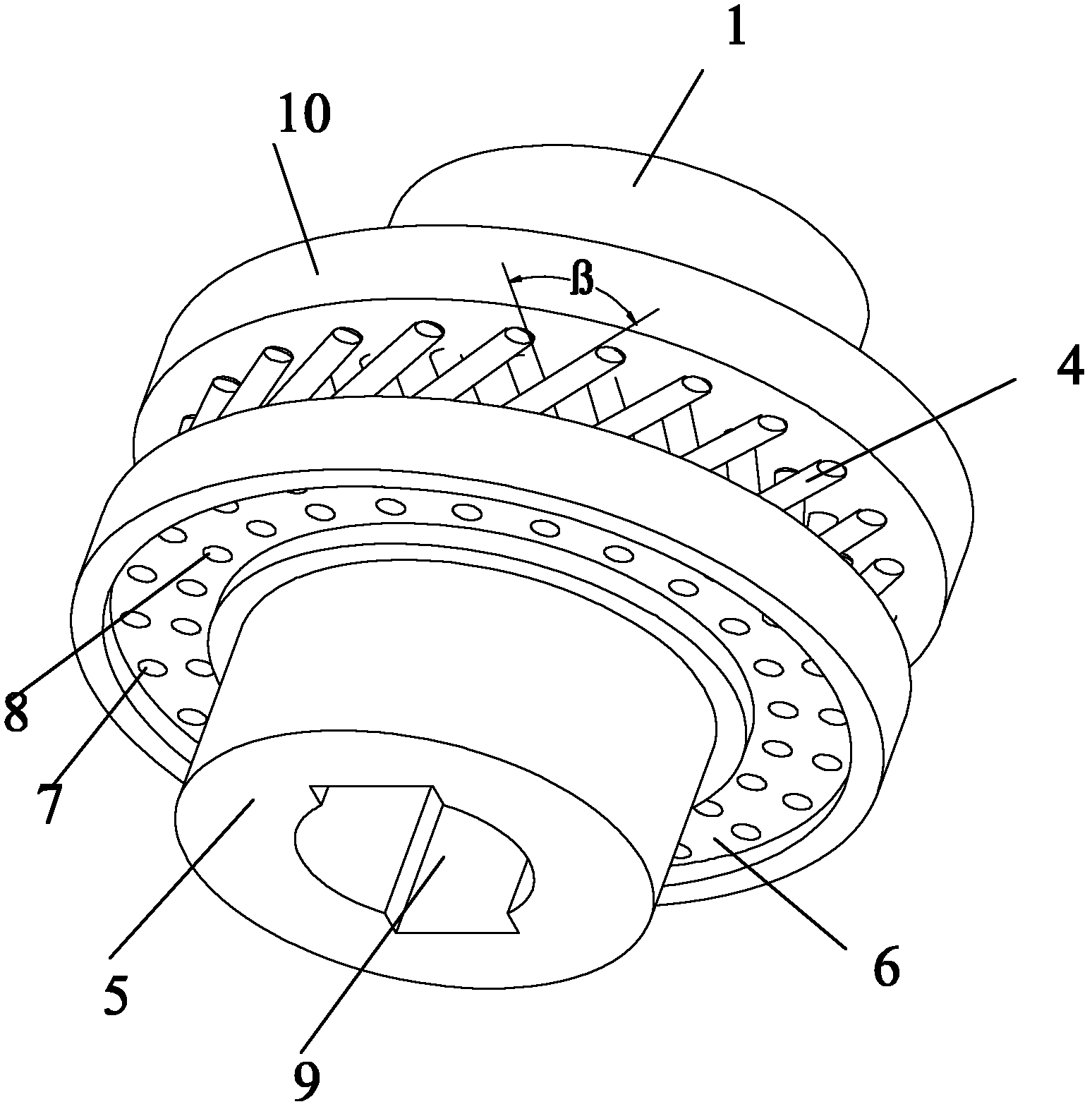

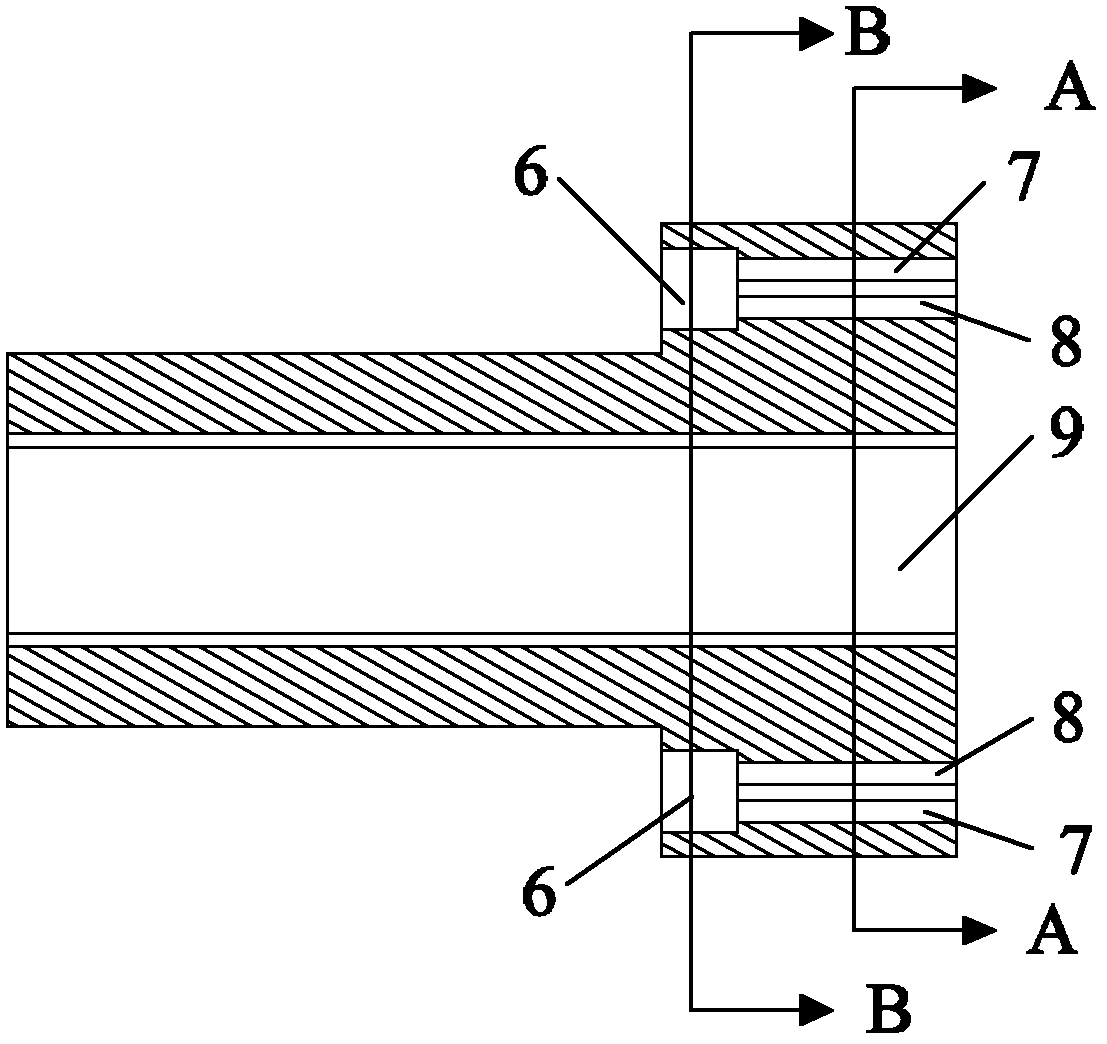

[0024] like figure 1 As shown, the elastic component in this embodiment is a twisted steel wire rope 4, and its two ends are fixedly connected with the first half coupling 1 and the second half coupling 5 respectively. The twisted steel wire ropes 4 are arranged at least once in the circumferential direction, and the twisted steel wire ropes 4 arranged in the same circle are parallel to each other. If the arrangement of twisted steel wire ropes is more than two turns, the twisted steel wire ropes of two adjacent turns are arranged at an angle, and the value range of the formed angle β is preferably 60°-160°.

[0025] Preferably, the end of the twisted...

Embodiment 2

[0033] The structure of this embodiment is basically the same as that of Embodiment 1, except that the elastic device in this embodiment is made of fiber, and the tensile strength of the fiber is greater than 500 MPa.

[0034] The elastic coupling of the present invention makes full use of the flexibility and rigidity of twisted steel wire ropes, has a simple structure, low cost, and is easy to manufacture. The all-metal structure can be used in various complex working conditions, easy to maintain, stable in performance, large in transmission torque, and capable of absorbing tests The impact of the motor, the shock absorption effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com