Combined filling station

A combined and filling technology, used in packaging, bottle filling, liquid bottling, etc., can solve problems such as unfavorable time and cost, and achieve the effect of simplifying product conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

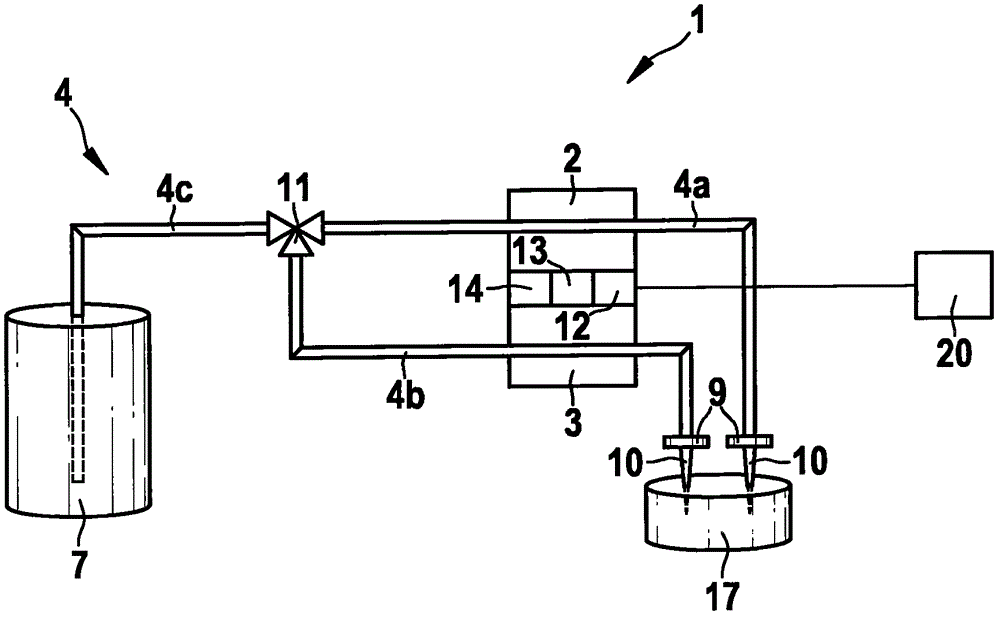

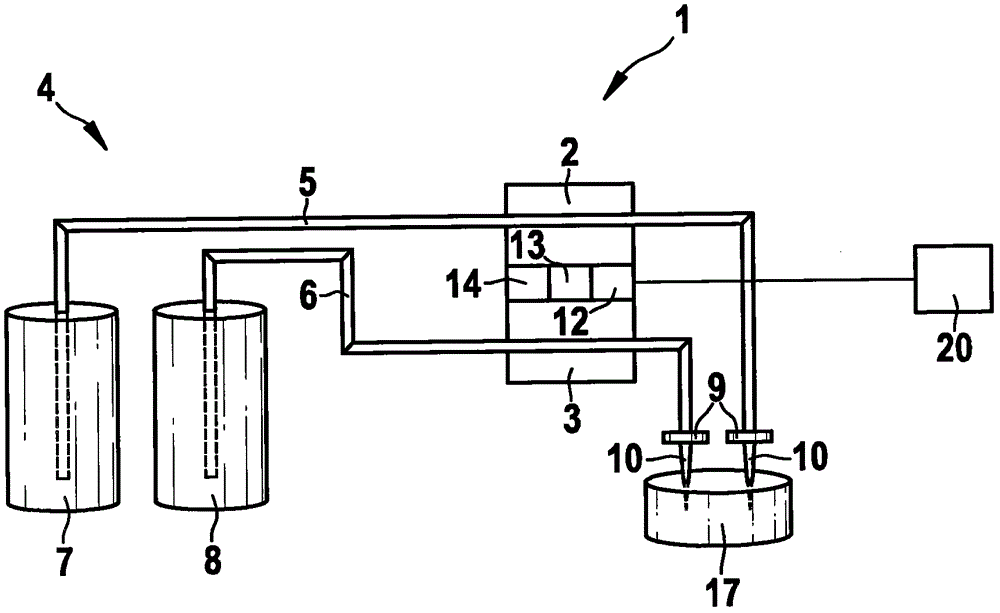

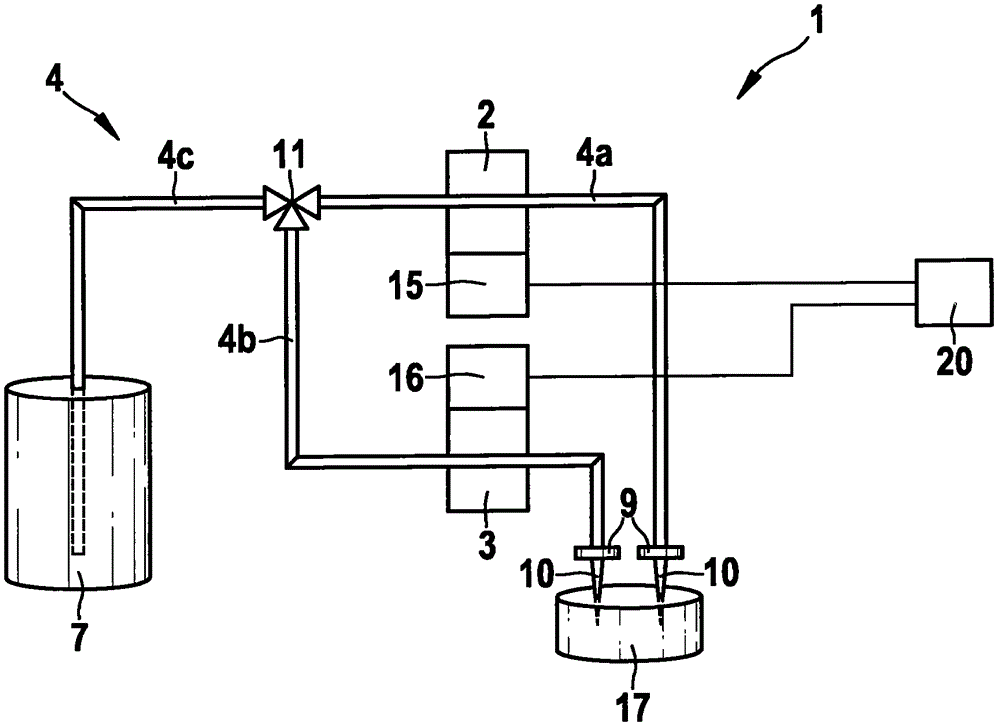

[0021] Refer below figure 1 The combined filling station according to the first preferred embodiment of the present invention is described in detail.

[0022] as by figure 1 The schematic diagram of the embodiment of the combined filling station 1 according to the invention can be seen, the combined filling station comprises a first conveying device 2 and a second conveying device 3, which pump through a pipeline device 4 Or take out the liquid that is stored in a storage container 7 . Here, the delivery devices 2 , 3 are of different types and can be hose pumps or rotary slide valve vacuum pumps or rotary piston pumps or rolling diaphragm pumps or time-pressure-filling systems. The line arrangement 4 comprises a distribution section 4c and a changeover / insertion device 11, on which a subsequent first line section 4a is tapped off from the distribution section 4c, the first line section It extends through the first conveying device 2 as far as the discharge point 9 . A sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com