Method for cultivating black fungus by Camellia oleifera Po

A technology of Camellia oleifera and black fungus, applied in the directions of botanical equipment and methods, application, fertilizer mixture, etc., can solve the problems of limited utilization of Camellia oleifera, rising prices, and tight supply of cottonseed hulls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

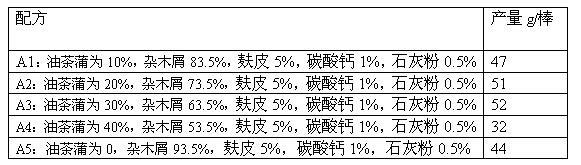

Examples

Embodiment 1

[0017] Embodiment 1: to make 1000 sticks of black fungus, the weight ratio in the compost proportioning is: miscellaneous sawdust 63.5%, camellia oleifera 30%, bran 5%, calcium carbonate 1%, lime powder 0.5% is example:

[0018] Need 270kg Camellia oleifera, 571.5kg sawdust, 45kg bran, 9kg calcium carbonate, 4.5kg lime powder.

[0019] Collect 270kg of camellia oleifera from the cracking of camellia oleifera fruit, dry or sun-dry, grind into crumbs with a machine, remove powder with a sieve, and select crumbs larger than 0.5 cm square. Pre-wet the screened Camellia oleifera, weigh 4.5kg of lime powder and 801kg of water to mix into lime water, add 324kg of lime water to the evenly spread Camellia oleifera, and mix while adding, so that Camellia oleifera Fully absorb, put a pile after adding lime water, and pre-wet for more than 6 hours.

[0020] Then dry mix 571.5kg miscellaneous sawdust, 45kg bran, and 9kg calcium carbonate evenly, and mix it with the pre-wetted camellia ole...

Embodiment 2

[0022] Embodiment 2: to make 1000 sticks of black fungus, the weight ratio in the compost proportioning is: miscellaneous sawdust 68%, camellia oleifera 25.7%, bran 5%, calcium carbonate 0.8%, lime powder 0.5% is example:

[0023] Need 231.3kg Camellia oleifera, 612kg sawdust, 45kg bran, 7.2kg calcium carbonate, 4.5kg lime powder.

[0024] Collect 231.3kg of Camellia oleifera from cracking of Camellia oleifera fruit, dry or sun-dry, grind into crumbs with a machine, remove powder with a sieve, and select crumbs larger than 0.5 cm square. Pre-wet the screened Camellia oleifera, weigh 4.5kg of lime powder and 801kg of water to mix into lime water, add 278kg of lime water to the evenly spread Camellia oleifera, and mix while adding, so that Camellia oleifera Fully absorb, put a pile after adding lime water, and pre-wet for more than 6 hours.

[0025] Then dry mix 612kg miscellaneous sawdust, 45kg bran, and 7.2kg calcium carbonate, and mix it with the pre-wetted Camellia oleifera...

Embodiment 3

[0027] Embodiment 3: to make 1000 sticks of black fungus, the weight ratio in the compost proportioning is: miscellaneous sawdust 65%, camellia oleifera 28.5%, bran 5%, calcium carbonate 1%, lime powder 0.5% is example:

[0028] Need 256.5kg Camellia oleifera, 585kg sawdust, 45kg bran, 9kg calcium carbonate, 4.5kg lime powder.

[0029] Collect 256.5 kg of Camellia oleifera from the cracking of camellia oleifera fruit, dry or sun-dry, grind into crumbs with a machine, sieve the powder with a sieve, and select crumbs larger than 0.5 cm square. Pre-wet the screened Camellia oleifera, weigh 4.5kg of lime powder and 801kg of water to mix into lime water, add 307.8kg of lime water to the evenly spread Camellia oleifera, and mix while adding, so that Camellia oleifera Pu is fully absorbed, after adding lime water, put it in a pile, and pre-wet it for more than 6 hours.

[0030] Then dry mix 585kg miscellaneous sawdust, 45kg bran, and 9kg calcium carbonate, and mix it with the pre-we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com