Method for extracting total saponins of cochinchinese asparagus root by using ultrasonic waves

An ultrasonic, total saponin technology, applied in pharmaceutical formulations, medical preparations containing active ingredients, antidote, etc., can solve the problems of low extraction rate, loss of extraction of effective substances of asparagus, easy to cause pollution, etc., and achieve economical improvement. Benefit, reduction of auxiliary substances and operation steps, effect of improving extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

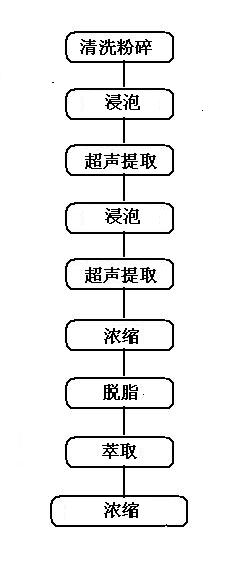

[0019] Example 1.

[0020] Take 100kg of asparagus that has passed the inspection, wash and dry; put it into a pulverizer to crush, pass through a 0.5mm sieve; add 2000kg of 80% ethanol to the powder and soak for 50 minutes; then use ultrasonic waves with a frequency of 30kHz at 60°C for 25 minutes Then filter again; then repeat the immersion and ultrasonic extraction again; combine the two filtrates, and concentrate them on a rotary evaporator to 150kg under reduced pressure; then recover the ethanol in the filtrate, then extract and degrease with ether, and then extract with saturated n-butanol 4 times, add 3 times the amount of saturated n-butanol for the first time, add 2 times the amount of saturated n-butanol for each of the last three times; finally recover the saturated n-butanol under reduced pressure, concentrate the extract, and then obtain 3.275 kg of total asparagine saponins.

[0021] After inspection, the extraction rate of total asparagine saponins is 3.275%, a...

Example Embodiment

[0022] Example 2.

[0023] Take 100kg of asparagus that has passed the inspection, wash and dry it; put it into a pulverizer to crush it, pass through a 0.5mm sieve; add 2100kg of 80% ethanol to the powder and soak it for 55 minutes; Then filter again; then repeat the immersion and ultrasonic extraction again; combine the two filtrates, and concentrate them on a rotary evaporator to 150kg under reduced pressure; then recover the ethanol in the filtrate, then extract and degrease with ether, and then extract with saturated n-butanol 4 times, add 3 times the amount of saturated n-butanol for the first time, add 2 times the amount of saturated n-butanol for each of the last three times; then recover the saturated n-butanol under reduced pressure, concentrate the extract, and finally obtain 3.371 kg of total asparagine saponins.

[0024] After testing, the extraction rate of total asparagine saponins is 3.371%, and the content of total asparagine saponins in the extract is 90.3%. ...

Example Embodiment

[0025] Example 3.

[0026] Take 100kg of asparagus that has passed the inspection, wash and dry it; put it into a pulverizer to crush it, and pass it through a 0.5mm sieve; add 2200kg of 80% ethanol to the powder and soak it for 60 minutes; Then filter again; then repeat the immersion and ultrasonic extraction again; combine the two filtrates, and concentrate them on a rotary evaporator to 150kg under reduced pressure; then recover the ethanol in the filtrate, then extract and degrease with ether, and then extract with saturated n-butanol 4 times, add 3 times the amount of saturated n-butanol for the first time, add 2 times the amount of saturated n-butanol for each of the last three times; then recover the saturated n-butanol under reduced pressure, concentrate the extract, and finally obtain 3.331 kg of total asparagine saponins.

[0027] After inspection, the extraction rate of total asparagine saponins is 3.331%, and the content of total asparagine saponins in the extract ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap