Improved discharge port structure of washing kettle

A discharge port and washing tank technology, which is applied in the field of large pressure vessel equipment and the discharge port structure of the washing tank, can solve the problems of wasted man-hours and low efficiency, and achieve the effects of clean cleaning, strong reliability and improved filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

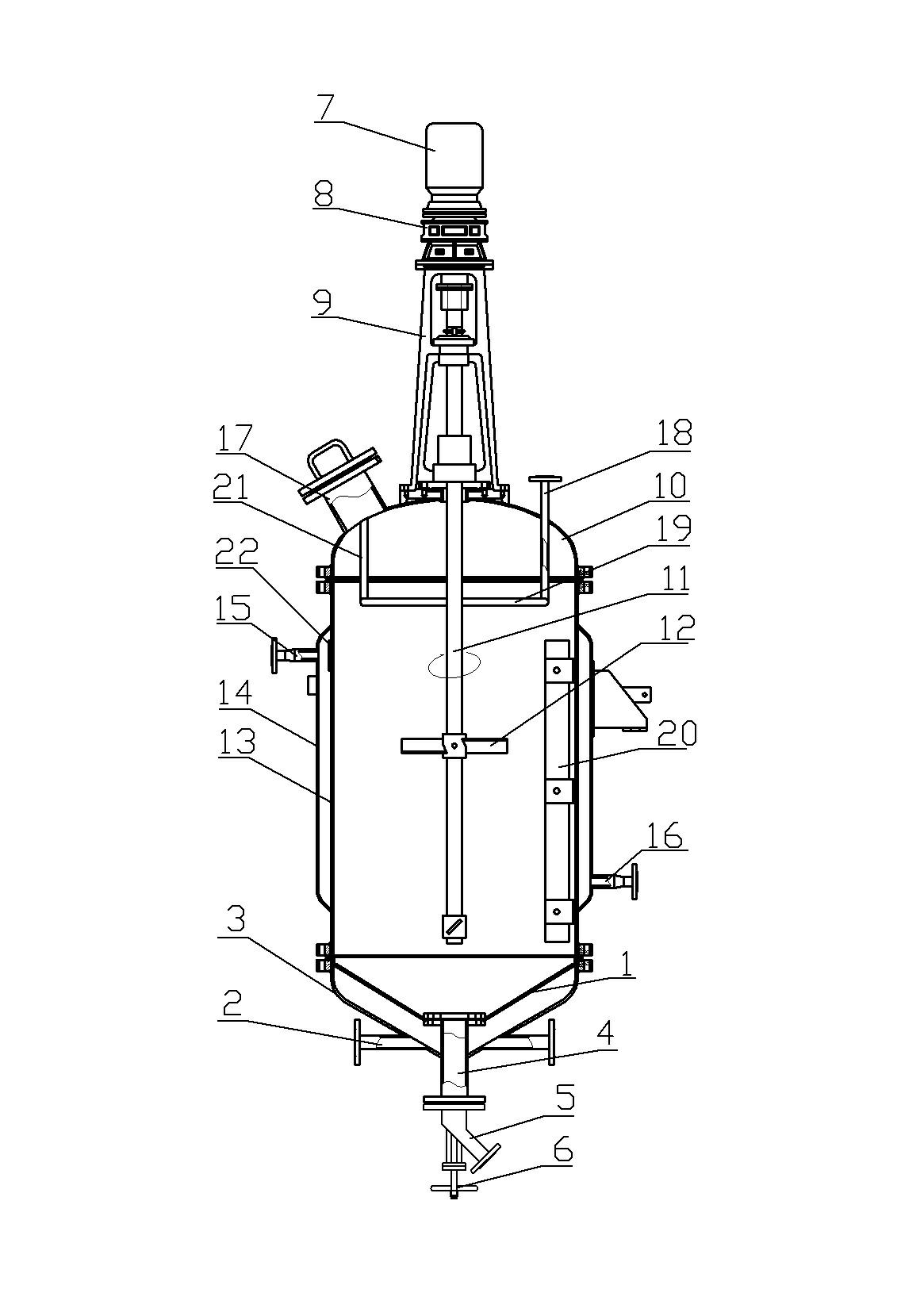

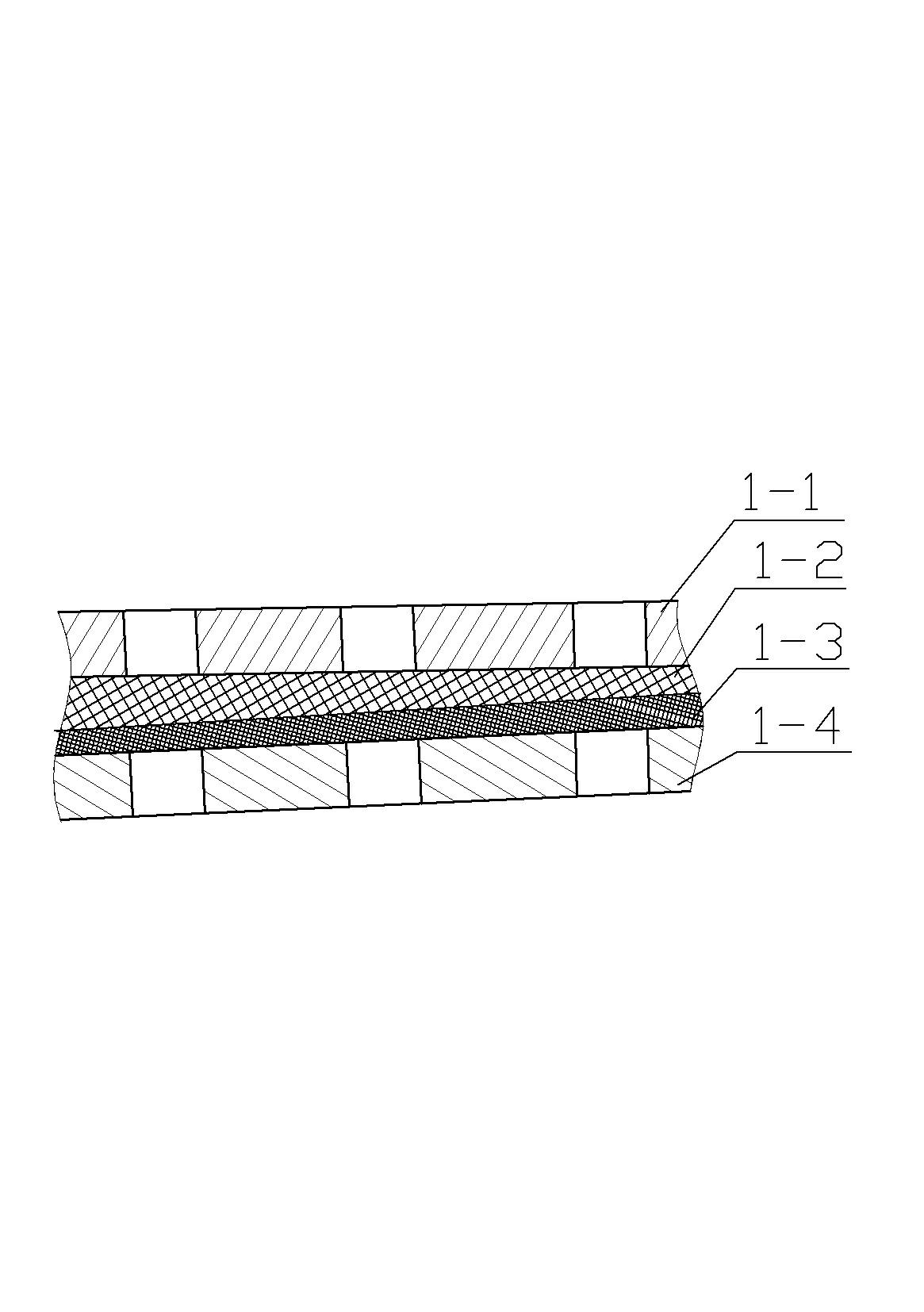

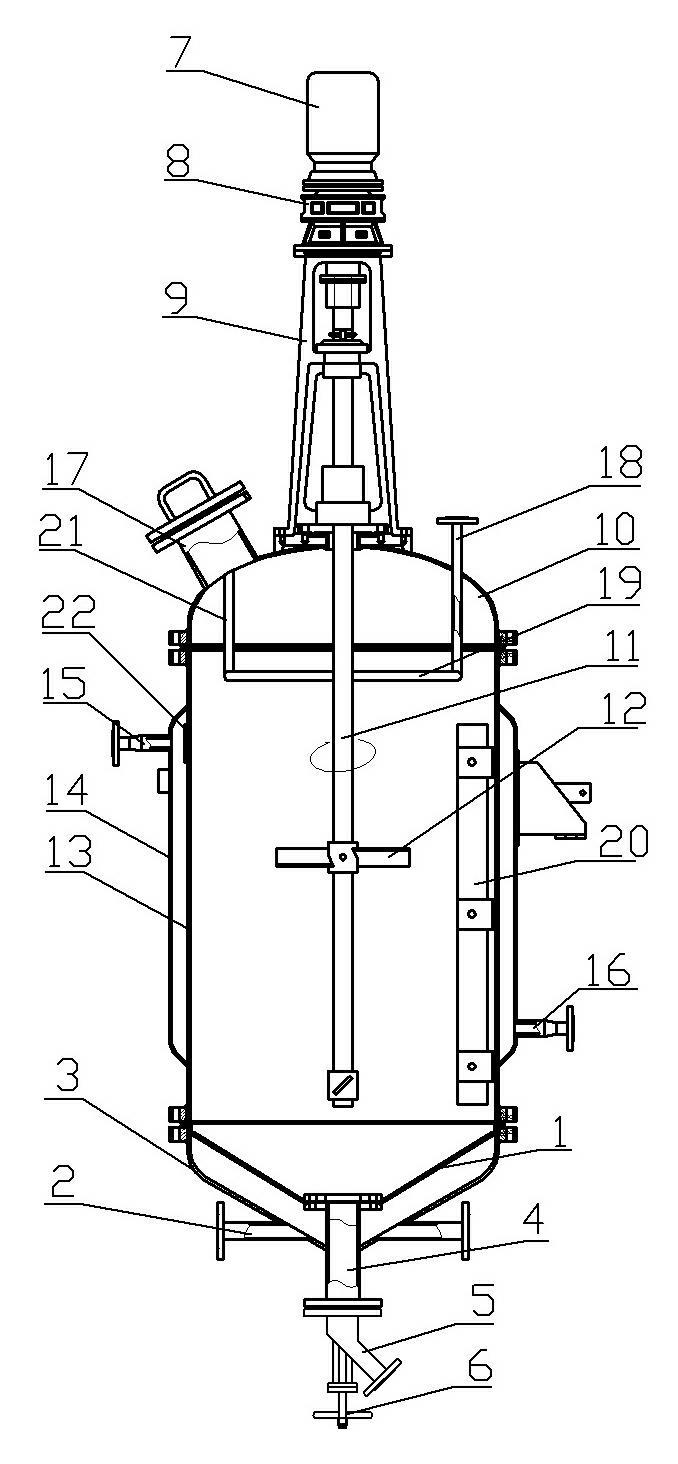

[0010] See figure 1 , figure 2 , the present invention comprises the body of the reaction kettle, the material discharge port 5, the washing water discharge port 2, the washing water discharge port is covered with a filter screen 1, the filter screen 1 is located above the conical lower head 3 of the reaction kettle body and is connected with the cone The lower head 3 forms a cavity, the washing water discharge port 2 is connected to the cavity, and the mesh surface surrounded by the filter screen 1 leaves an empty opening in the middle, and the empty opening is connected to the material discharge port 5 at the bottom of the reactor body through the connecting pipe 4. The filter screen 1 includes an upper filter screen plate 1-1, a lower filter screen plate 1-4, an intermediate layer of silk screen 1-2, and a layer of filter cloth 1-3, and the filter cloth 1-3 is laid under the screen 1-2. The screen surface surrounded by the filter screen 1 is also in the shape of a conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com