Error real time online compensation method for precise servo forging press

A compensation method and error compensation technology, applied to the driving device of the forging press, etc., to achieve the effect of improving the forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

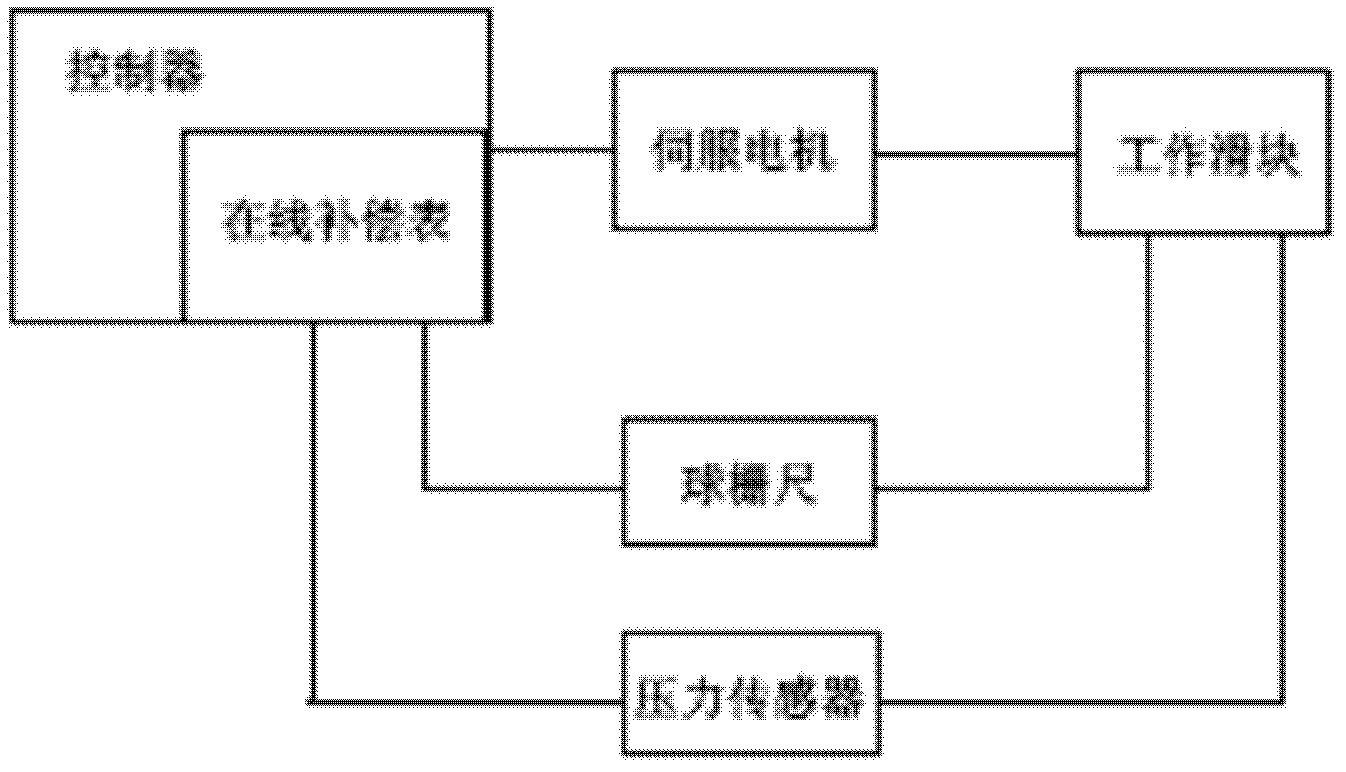

[0017] The online measurement module of the present invention is composed of a ball grid scale and a pressure strain gauge sensor, and the ball grid scale is installed on the inner side of the fuselage wall, parallel to the moving direction of the working slider. The ball scale is used to measure the real-time position of the working slider and transmit the position information to the controller; two pressure strain gauge sensors are installed in the middle section of the inner side of the press body wall. The installation height is flush with the mold position. The pressure strain gauge converts the deformation of the fuselage under pressure into a voltage value, and transmits the measured value to the controller.

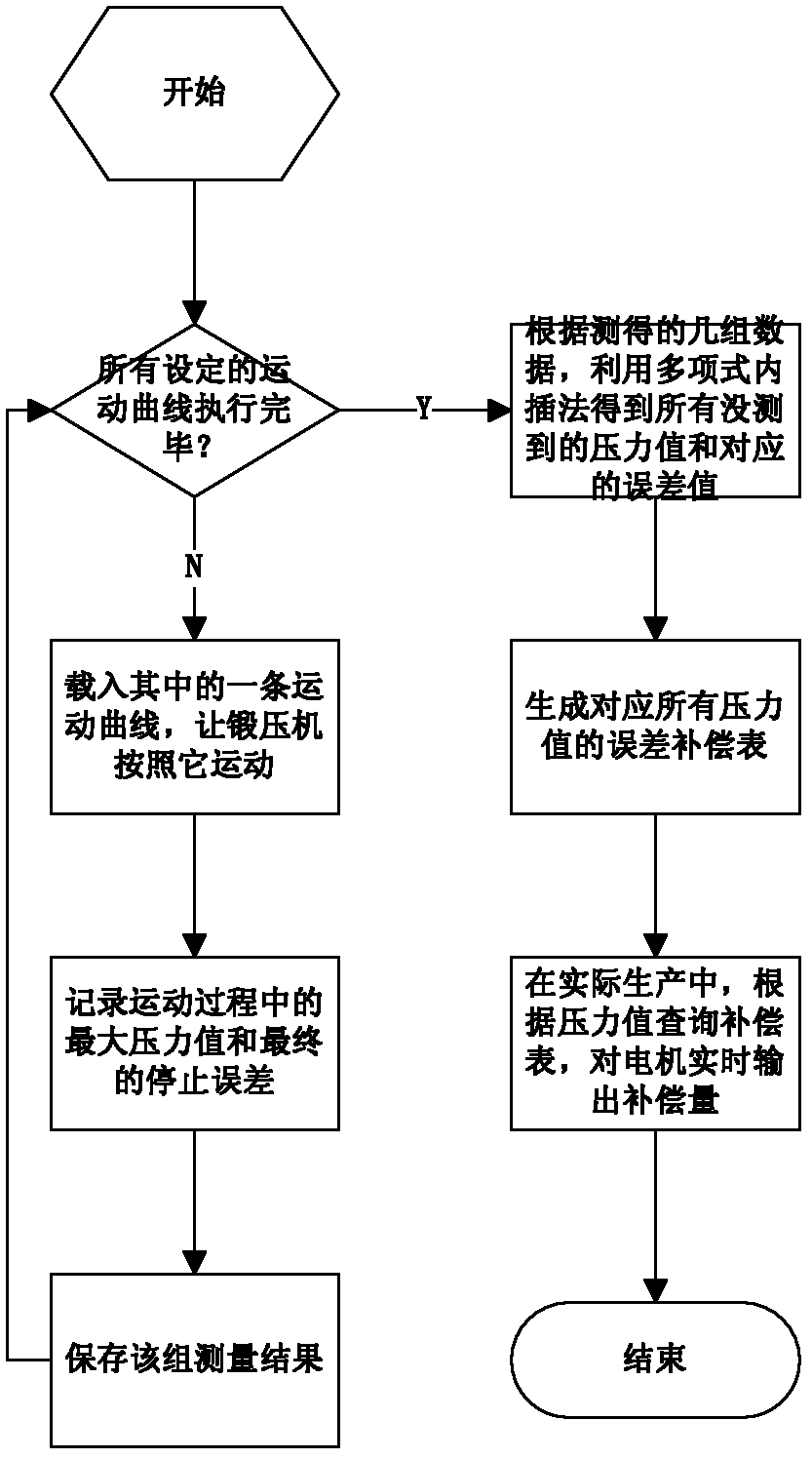

[0018] Such as figure 1 As shown, the ball scale and the pressure strain gauge sensor send the state of the working slider to the controller in real time, and the controller dynamically compensates the servo motor in real time according to the online compensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com