Spatial six-mobility drilling robot mechanism

A six-degree-of-movement robot technology, applied in drilling/drilling equipment, manipulators, program-controlled manipulators, etc., can solve the problems of small working space, accumulation of joint errors, and inflexible movements of parallel robots, and achieve high-precision operations , good error compensation, simple and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

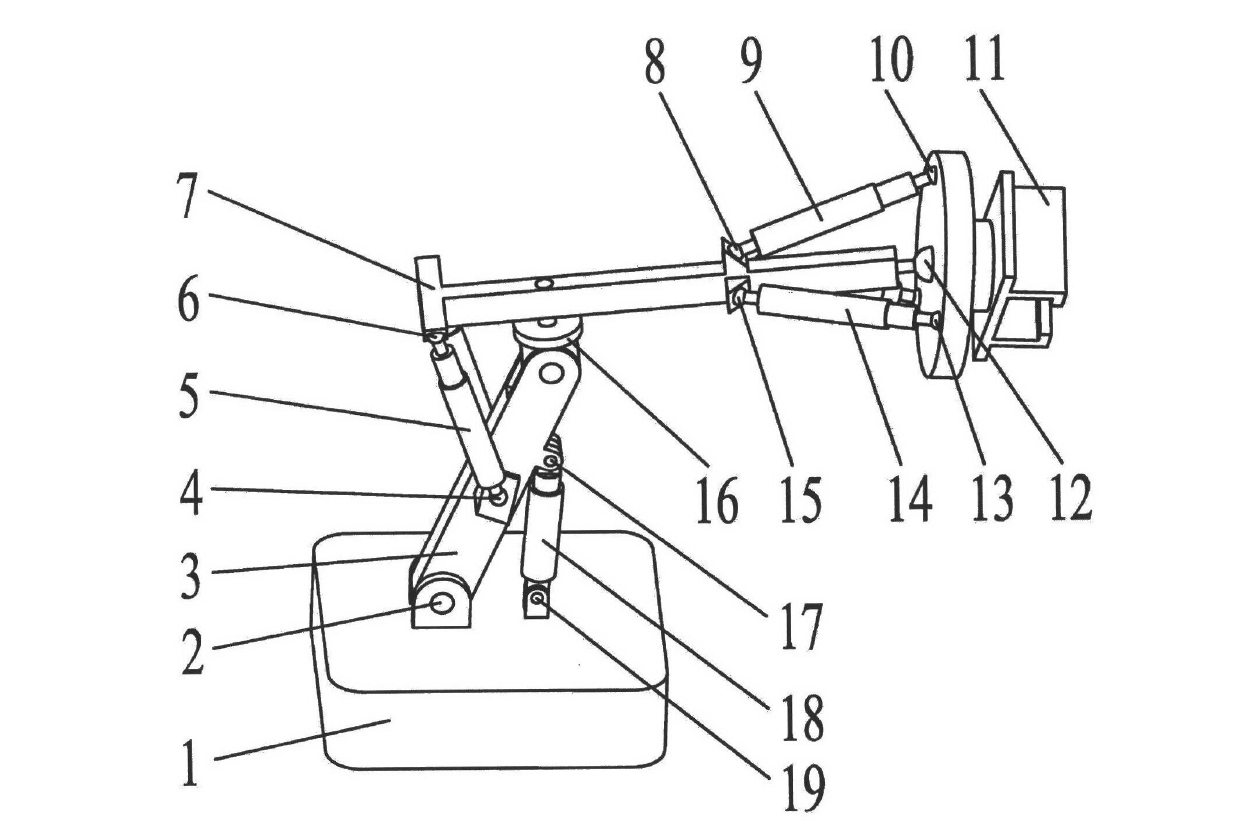

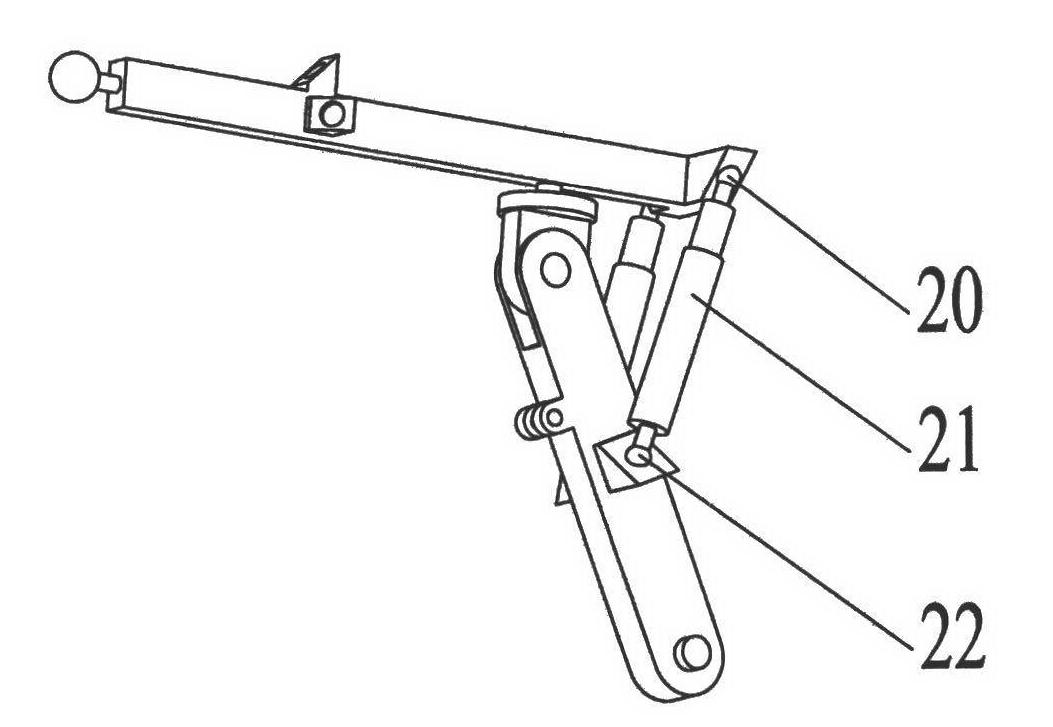

[0021] control figure 1 , 2 , 3 and 4, the six-degree-of-space drilling robot mechanism is composed of a one-dimensional rotating arm mechanism, a two-dimensional rotating forearm mechanism and a three-dimensional rotating platform mechanism.

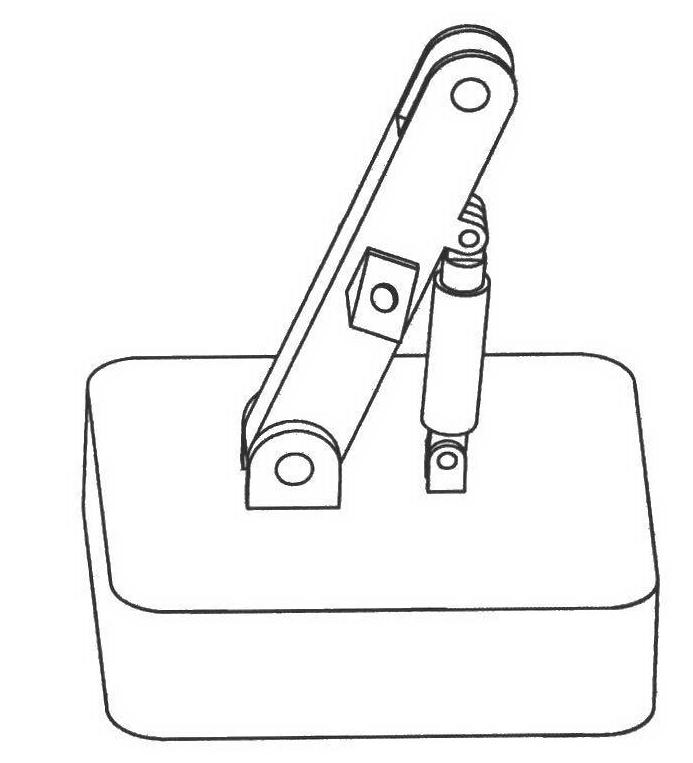

[0022] control figure 1 , 2 , the one-dimensional rotating arm mechanism is composed of a frame 1, a one-dimensional rotating arm 3 and a first linear drive 18, and the one-dimensional rotating arm 3 is connected to the frame 1 through the first rotating pair 2, and the first One end of the linear drive 18 is connected to the frame 1 through the second rotating pair 19 , and the other end is connected to the one-dimensional rotating arm 3 through the third rotating pair 17 . The first linear driver 18 drives the one-dimensional rotating arm 3 to realize the one-dimensional rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com