Molding equipment for food packaging tool

A molding equipment and food packaging technology, applied in recycling technology, plastic recycling, etc., can solve the problems of leftover pollution, high production cost, low production efficiency, etc., and achieve the goal of reducing production cost, avoiding pollution and waste, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

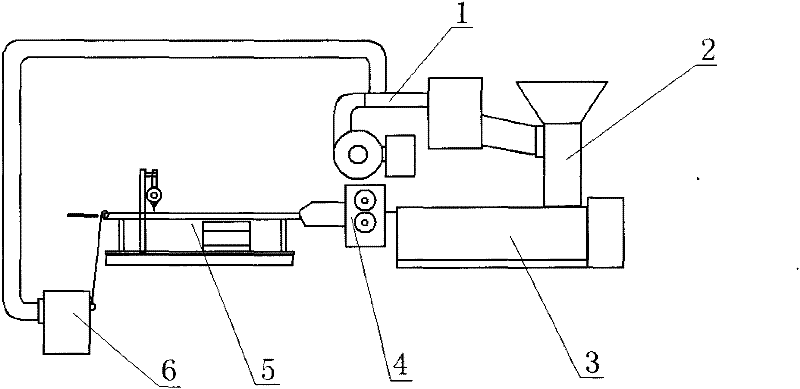

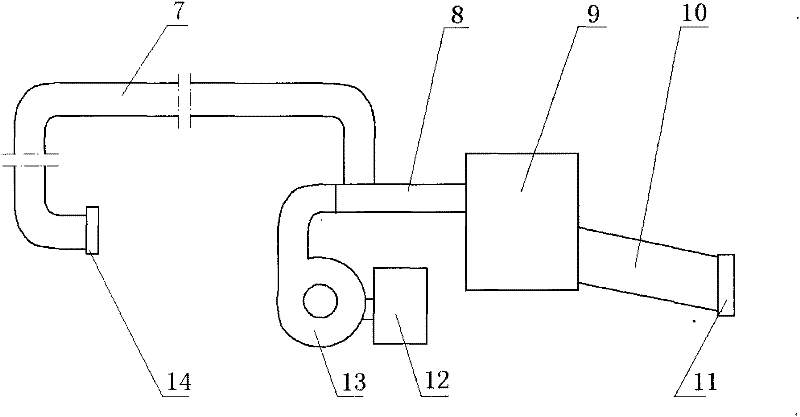

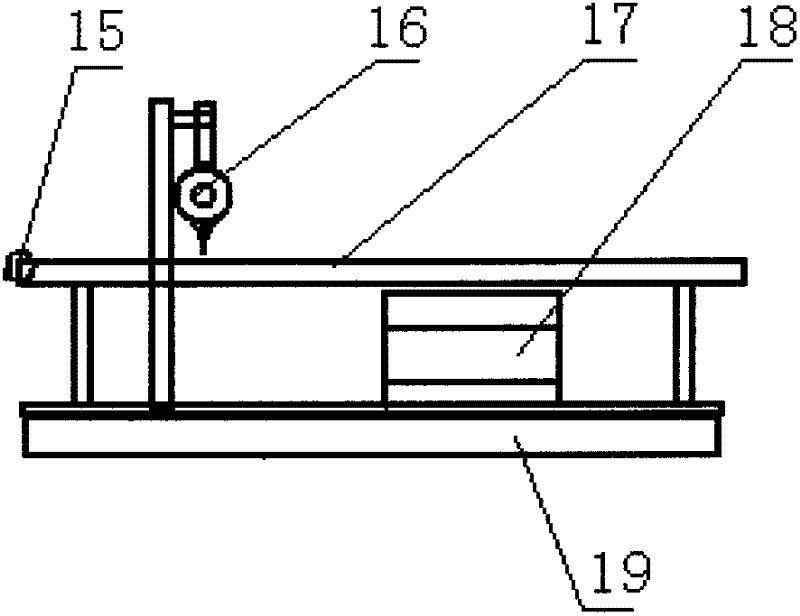

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the food packaging molding equipment includes a feeding mechanism 2, an extrusion part 3, a sheet extruding part 4, a forming part 5, a scrap grinder 6 and a scrap recycling device 1, and there is a gap between the scrap grinder 6 and the feeding mechanism 2. The leftover material recovery device 1, the leftover material recovery device 1 comprises a pipeline 7, a leftover material particle inlet pipe 8, a power mechanism 12, a fan 13, a leftover material particle collection box 9 and a leftover material particle conveying pipe 10, and the fan 13 is communicated with the leftover material particle inlet pipe 8, The leftover particle inlet pipe 8 leads into the leftover particle collection box 9, and one end of the pipeline 7 has a leftover material pulverizer connection end 14, and the other end of the pipeline 7 leads into the leftover particle inlet pipe 8, and one end of the leftover particle conveying p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com