Chiral metal complex catalyst

A technology of chiral catalysts and metal complexes, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, catalytic reactions, etc. Low efficiency and other problems, to avoid poisoning of users, stable properties, and beneficial to recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

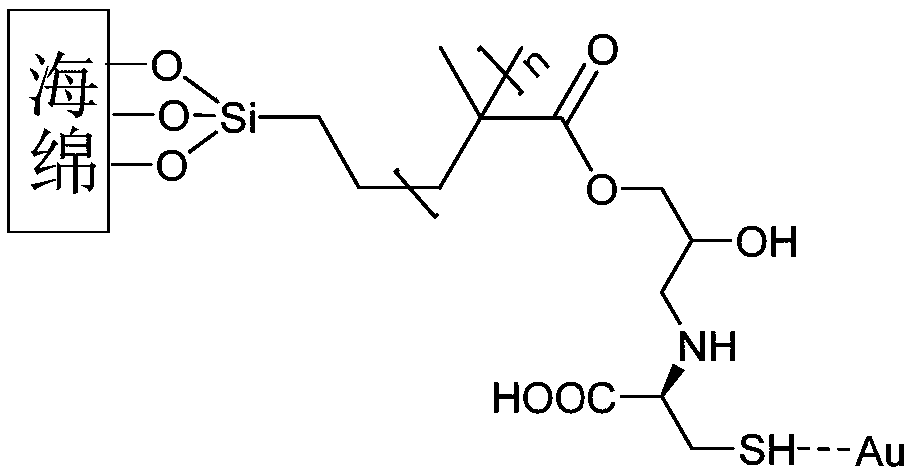

Embodiment 1

[0075] A sponge-loaded chiral metal complex, the sponge-loaded chiral complex is made of a sponge, a silylating agent, a chiral ligand, and copper, wherein the sponge is polydimethyl Siloxane sponge (PDMS), the silylating agent is vinyltrimethoxysilane with propylene oxide modified at the end group, and the chiral ligand is L-cysteine shown in the following formula, and The silylating agent is supported on the surface of the sponge by reacting with the surface hydroxyl groups of the sponge, and the chiral ligand is bonded to the carboxyl group of the silylating agent through a covalent bond and connected to the surface of the sponge. Wherein, the structure of the chiral ligand is shown below, and the effect diagram of the chiral complex catalyst supported by the sponge is shown in figure 1 shown.

[0076]

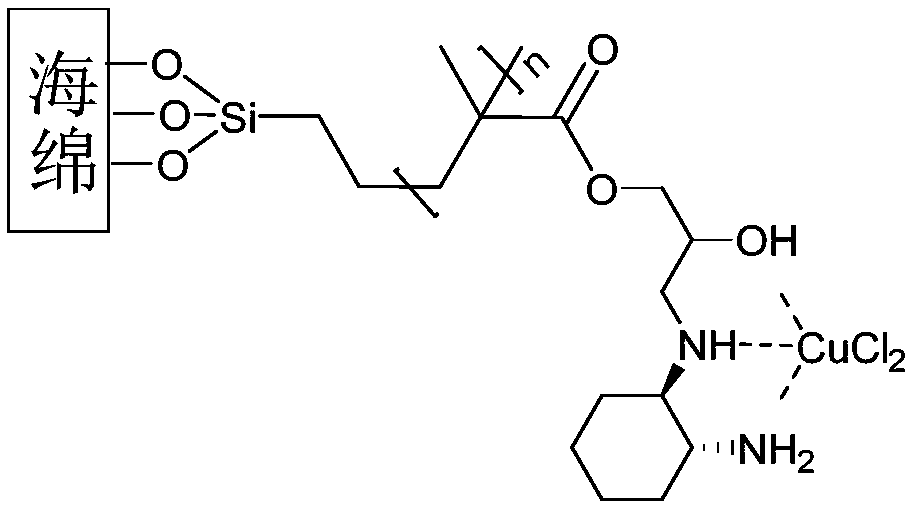

Embodiment 2

[0078] A sponge-loaded chiral metal complex, the sponge-loaded chiral complex is made of a sponge, a silylating agent, a chiral ligand, and copper, wherein the sponge is polydimethyl Silicone sponge (PDMS), the Linker reagent is vinyltrimethoxysilane with propylene oxide modified at the end group, and the chiral ligand is (1R, 2R)-cyclohexanedi amine, and the silylating agent is loaded on the surface of the sponge by reacting with the surface hydroxyl of the sponge, and the chiral ligand is bonded and connected to the modified silylating agent through a covalent bond. Sponge surface. Wherein, the structure of the chiral ligand is shown below, and the effect diagram of the chiral complex supported by the sponge is shown in figure 2 shown.

[0079]

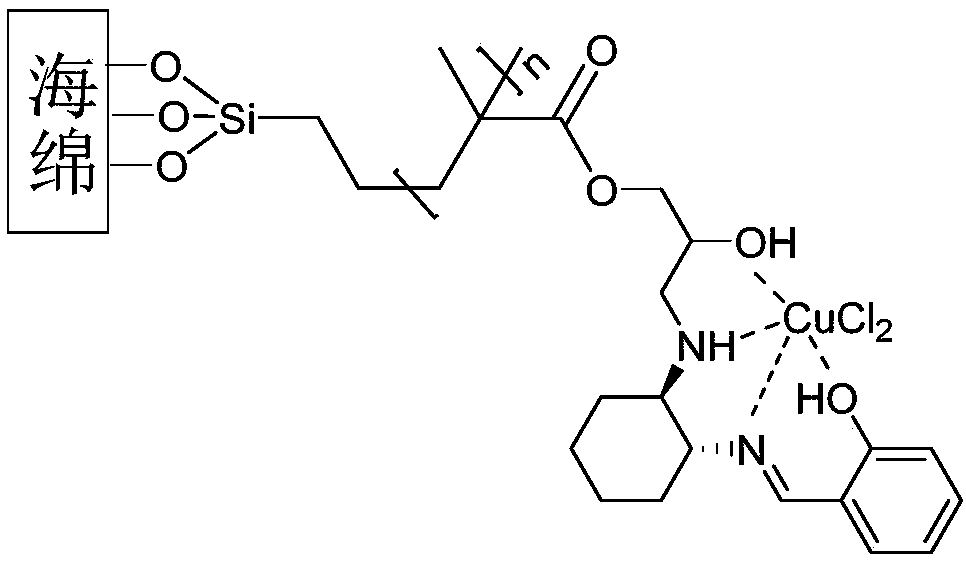

Embodiment 3

[0081] A sponge-loaded chiral metal complex, the sponge-loaded chiral complex is made of a sponge, a silylating agent, a chiral ligand and copper, wherein the sponge is polydimethyl Siloxane sponge (PDMS), the silylating agent is vinyltrimethoxysilane modified with propylene oxide at the end group, and the chiral ligand is (1R, 2R)-cyclohexyl as shown in the following formula Diamine and salicylaldehyde, and the silylating agent is loaded on the surface of the sponge by reacting with the surface hydroxyl groups of the modified sponge, and the chiral ligand is covalently bonded to the modified silanized The amino group and carboxyl group of the reagent are sequentially bonded and connected on the surface of the sponge. Wherein, the structure of the chiral ligand is shown below, and the effect diagram of the chiral complex supported by the sponge is shown in image 3 shown.

[0082]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com