Thermal head, thermal printer and manufacturing method for the thermal head

A thermal head and heating resistor technology, applied in printing and other directions, can solve the problems of insufficient performance and high thermal insulation performance, and achieve the effects of reducing power consumption, prolonging duration, and inhibiting thermal diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0043] Next, the thermal head, the printer, and the method of manufacturing the thermal head according to the first embodiment of the present invention will be described with reference to the drawings.

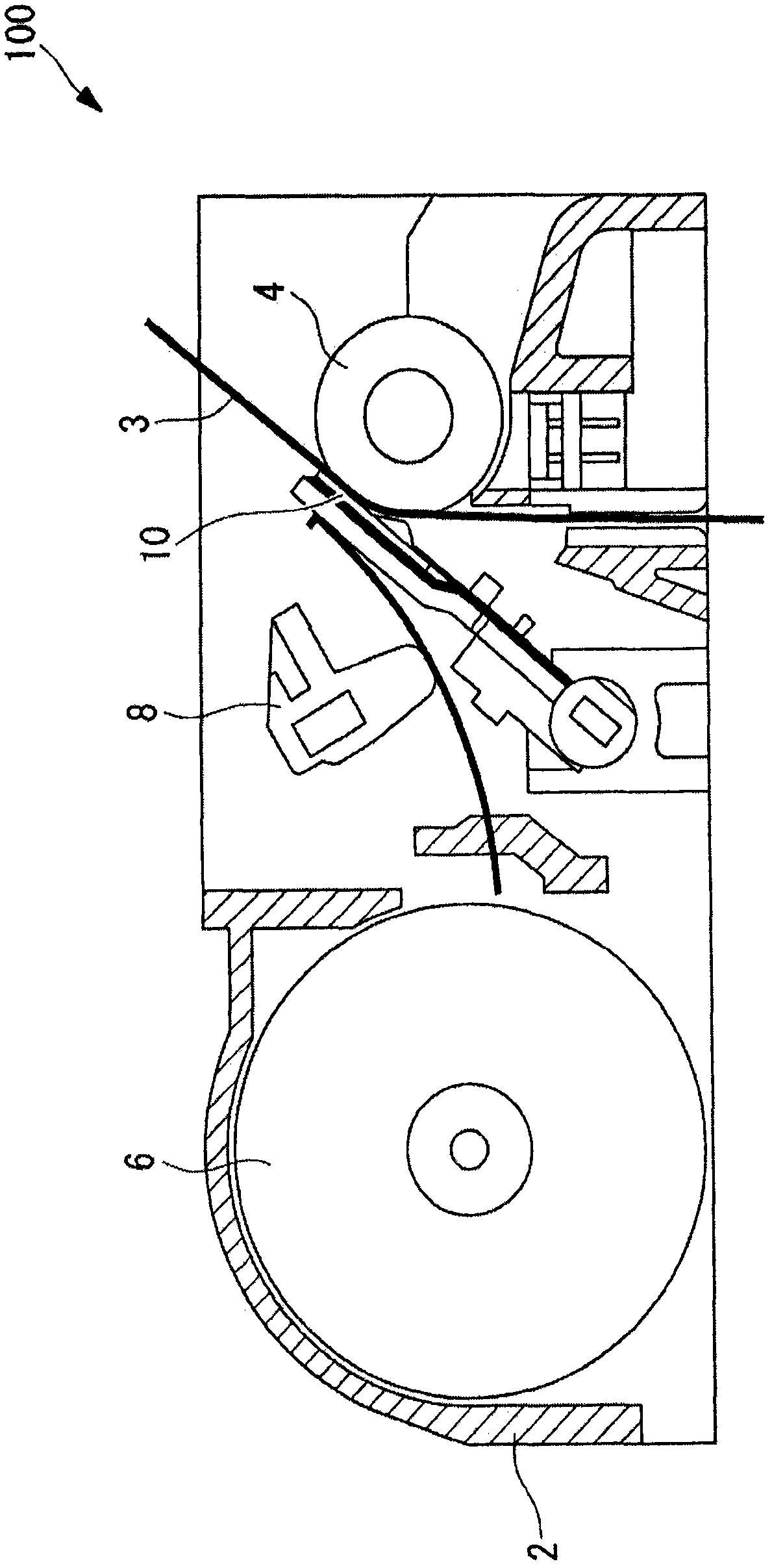

[0044] A thermal printer (printer) 100 according to this embodiment includes a main body frame 2, a platen roller 4 arranged horizontally, a thermal head 10 arranged to face the outer peripheral surface of the platen roller 4, A paper feeding mechanism 6 that conveys a printing object such as thermal paper (thermal recording medium) 3 to and from the thermal head 10 and a pressing mechanism 8 that presses the thermal head 10 against the thermal paper 3 with a predetermined pressing force.

[0045] The thermal paper 3 and the thermal head 10 are pressed against the platen roller 4 by the action of the pressing mechanism 8 . Thus, the load of the platen roller 4 is applied to the thermal head 10 via the thermal paper 3 .

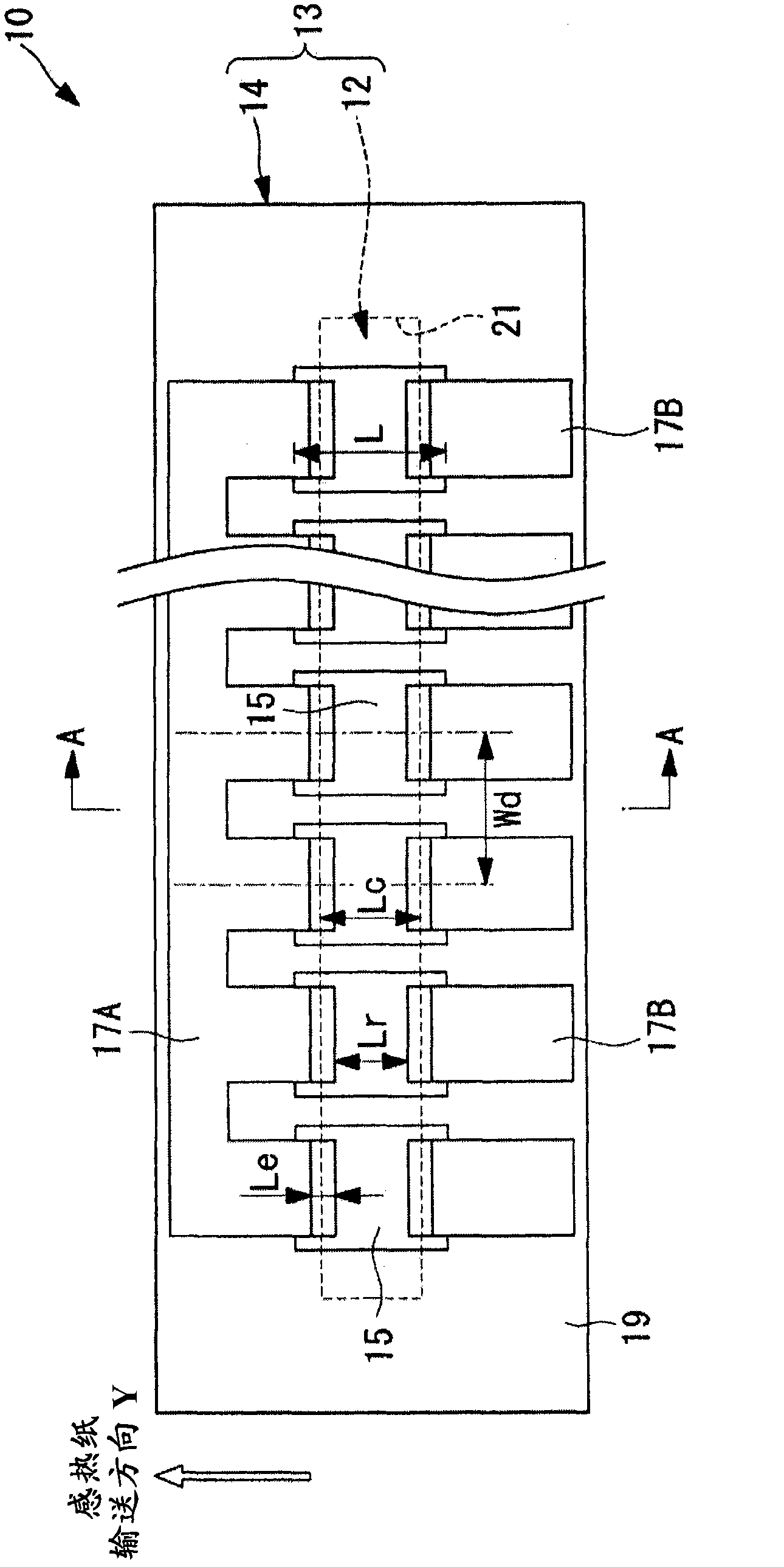

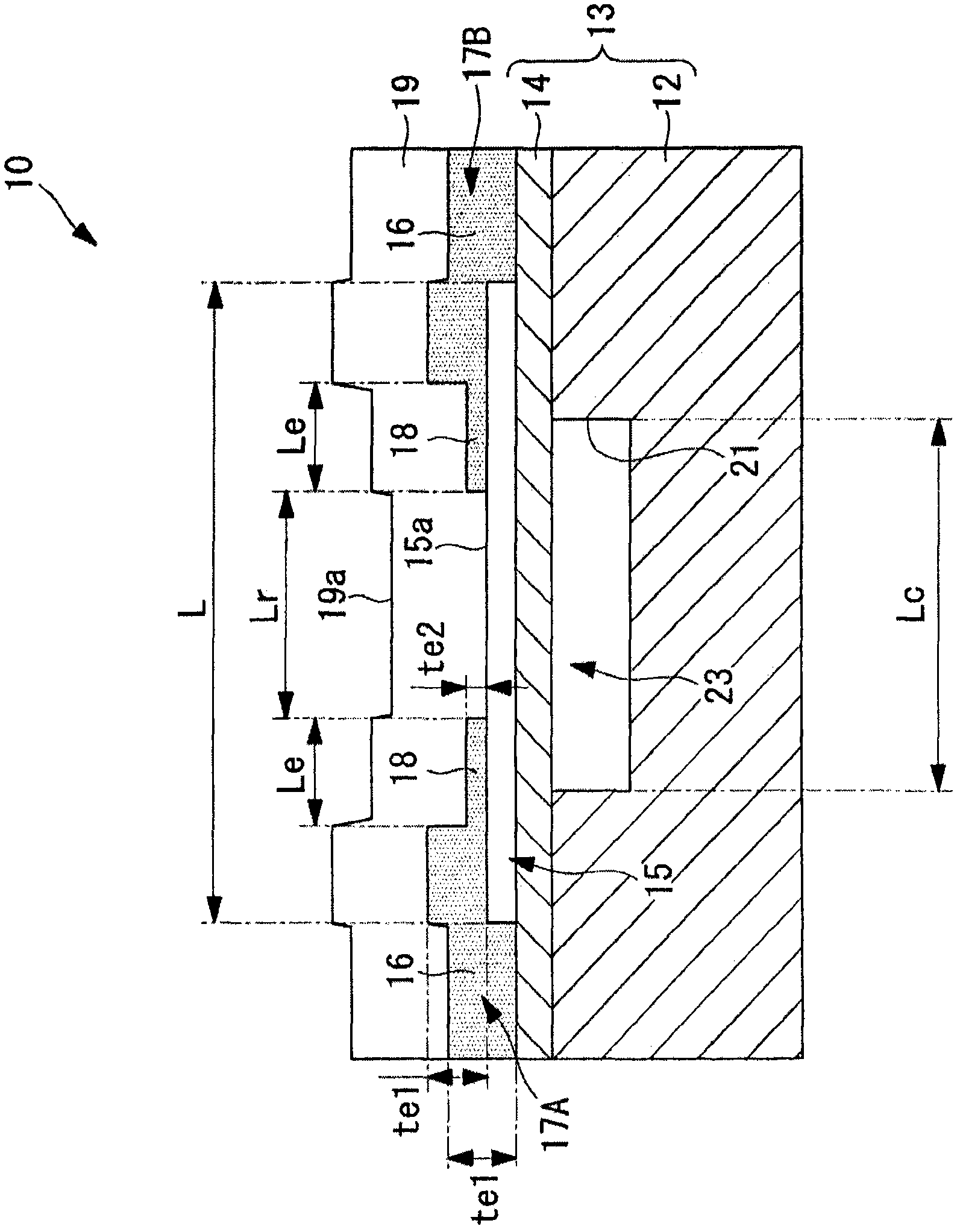

[0046] Such as figure 2 and image 3 As shown, the t...

no. 2 approach

[0098] Next, the thermal head, the printer, and the method of manufacturing the thermal head according to the second embodiment of the present invention will be described.

[0099] The thermal head 110 involved in this embodiment is as Figure 11 As shown, the electrode portions 117A, 117B include the low thermal conductivity portion 118 made of a material having a lower thermal conductivity than other regions and a resistance value lower than that of the heating resistor 15 in the region facing the hollow portion 23 , which is similar to that of the first embodiment. different ways. Hereinafter, parts common to those of the thermal head 10 , the thermal printer 100 , and the manufacturing method and structure of the thermal head according to the first embodiment are denoted by the same reference numerals and descriptions thereof are omitted.

[0100] The electrode portions 117A, 117B have a substantially uniform film thickness over the entirety. The part where the electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com