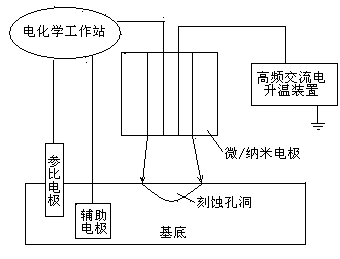

Electrochemical micromachining method for ZnO substrate with high-frequency alternating-current (AC) electric heating technology

A high-frequency alternating current and electrochemical technology, applied in scanning probe technology, scanning probe microscopy, measuring devices, etc., can solve the problems of polluting the environment, affecting the potential of the reference electrode, inconvenient to use, etc. The effect of simple, inexpensive processing routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

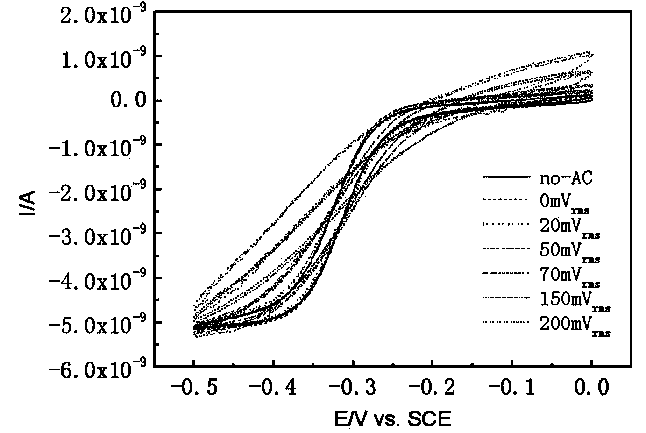

Method used

Image

Examples

Embodiment 3

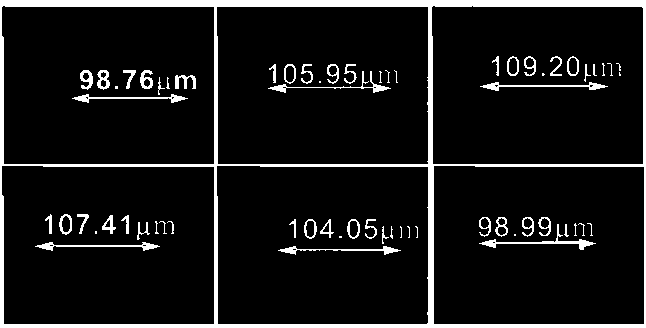

[0025] Examples 3-40 The experimental steps are similar to the above-mentioned examples, the difference lies in the frequency of the applied high-frequency alternating current, the concentration of the etching solution, and the etching time. The specific conditions and etching effects are shown in Table 1 (where "+ "Represents good etching effect, "-" represents poor etching effect).

[0026] Table 1

[0027]

[0028] The microelectrode-based heating electrode of the present invention can be applied to electrochemical micro / nano processing technology, and its main advantages are: (1) It is simpler, more convenient and faster than other electrode heating methods; (2) It can obtain And maintain a very high surface temperature for a relatively long period of time. Therefore, it is expected to significantly improve the processing resolution of diffusion-controlled and kinetic-controlled systems; (3) In principle, this method can obtain a smaller heating area than laser spot he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com