Device for producing powdery monoammonium phosphate by using extraction spent acid

A technology of monoammonium phosphate and raffinate acid, which is applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of insufficient total nitrogen content of the product and difficult control of product moisture, and achieve the effect of increasing the total nitrogen content and working stably and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

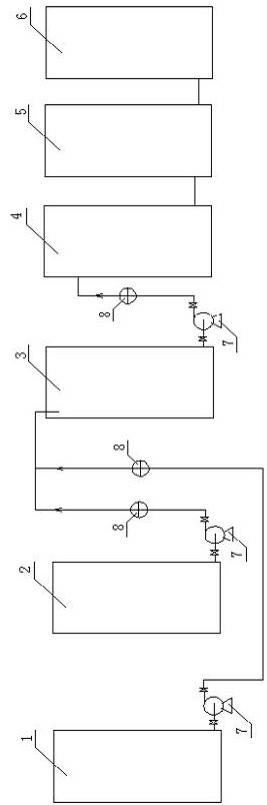

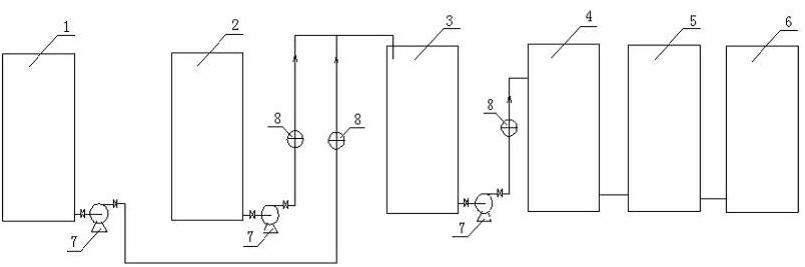

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] Such as figure 1 As shown, a device for producing powdered monoammonium phosphate by using raffinate acid, including a wet-purified phosphoric acid raffinate tank 1, a dilute phosphoric acid storage tank 2, an ammoniation reactor 4, a slurry concentrator 5, and a product spray drying Device 6, set the acid distribution tank 3 before the ammonia reactor 4, the size of the acid distribution tank 3: φ11280, H=1000 0, Wet purification phosphoric acid raffinate tank 1 is connected to acid distribution tank 3 through pipelines, and a delivery pump 7 and a meter 8 are arranged on the pipelines; dilute phosphoric acid storage tank 2 and acid distribution tank 3 are connected through pipelines, And the pipeline is provided with a delivery pump 7 and a meter 8, and the acid tank 3, the ammoniation reactor 4, the slurry concentrator 5, and the product spray dryer 6 are sequent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com