Drying dehydration plant of electric heating vibrating screen

A technology of dehydration device and vibrating screen, which is applied in the direction of heating device, drying, drying machine, etc., can solve the problems of poor coal dehydration effect and high transportation cost, achieve reasonable and reliable structural design, safe and convenient operation process, and overcome transportation cost higher effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

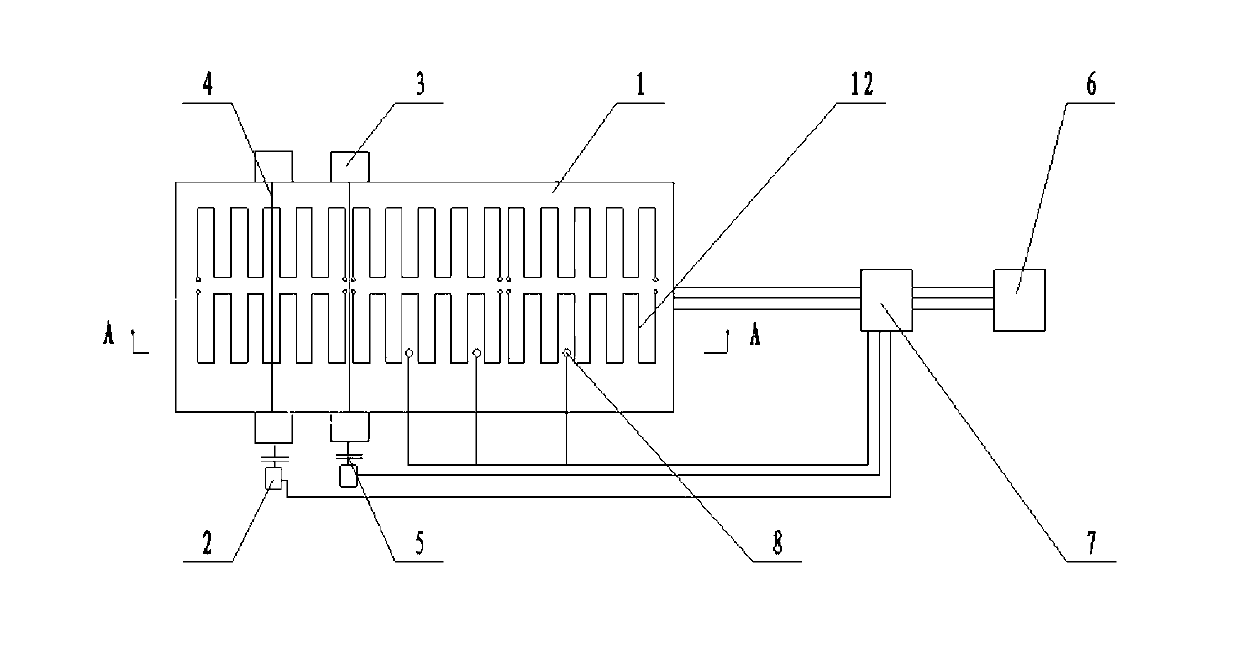

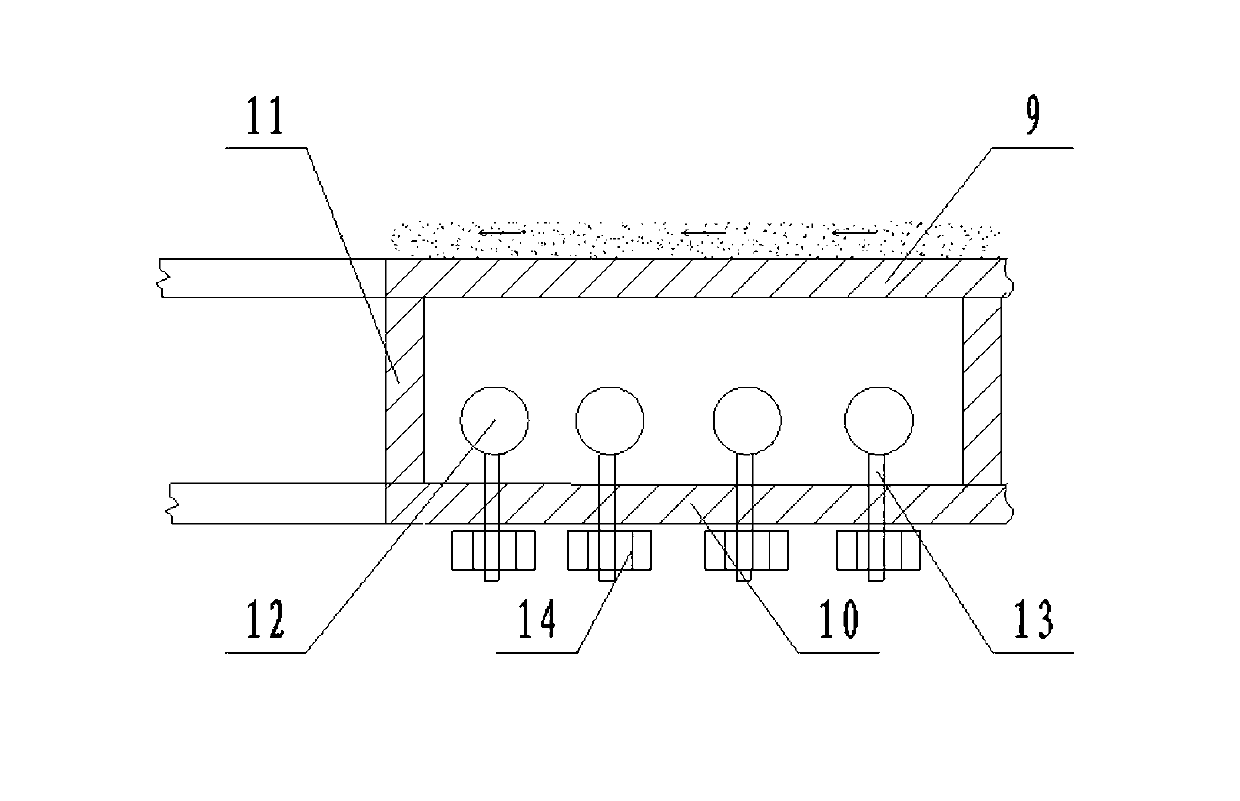

[0010] The electric heating vibrating screen drying and dehydrating device includes a sieve body 1 and a motor 2. Exciting bodies 3 are fixed on the left and right sides of the sieve body 1, and a transmission shaft 4 is eccentrically arranged between the vibrating bodies 3 corresponding to the left and right directions, and the motor 2 and the excitation body 3 are provided with a connection plate 5 connected to both, and also include a power supply 6, a control cabinet 7 and an infrared probe 8 located in the screen body 1, and a heat conduction plate 9 is arranged on the upper surface of the screen body 1. 1. A heat insulation board 10 is arranged on the lower end surface, and a support column 11 fixed between the heat conduction plate 9 and the heat insulation board 10 is arranged, and a number of curved electric heating tubes 12 are arranged in the screen body 1, and the electric heating tube 12 is fixed There is a screw 13 passing through the side wall of the screen body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com