Bean dreg drying device

A technology for drying equipment and bean dregs, which is applied in the field of bean dregs drying equipment to achieve the effects of convenient storage, lower discharge temperature, and prevention of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

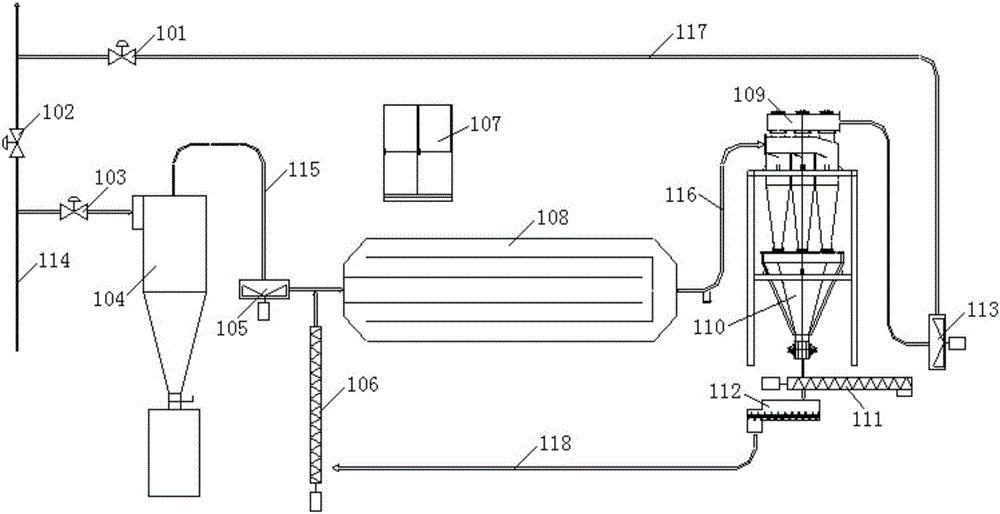

[0017] refer to figure 1 , the bean dregs drying equipment includes a feeder 106, a multi-ring drum dryer 108 and multiple groups of cyclone receivers 109, the feed end of the multi-ring drum dryer 108 is connected to the feeder 106, and the discharge end is connected to The feed end of multiple groups of cyclone receivers 109, the discharge end of multiple groups of cyclone receivers 109 are connected to the discharge distributor 111 and the return material quantitative feeder 112 through the discharge air locker 110, and the return material quantitative feeder 112 is connected to the feeder 106 through the return pipe 118. One end of the heat exchange pipe of the multi-ring drum dryer 108 is connected to the smoke inlet pipe 115, and the other end is connected to the first smoke outlet pipe 116. The smoke inlet pipe 115 is connected to the boiler. The smoke exhaust pipe 114 and the smoke inlet pipe 115 are provided with a flue gas dust collector 104, and the smoke inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com