Double-layer distillation tower

A distillation tower and double-layer technology, applied in the component field of oil refining equipment, can solve the problems of waste of raw materials, poor distillation and deacidification effect, etc., achieve the effect of uniform oil distribution, avoid waste, and increase production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

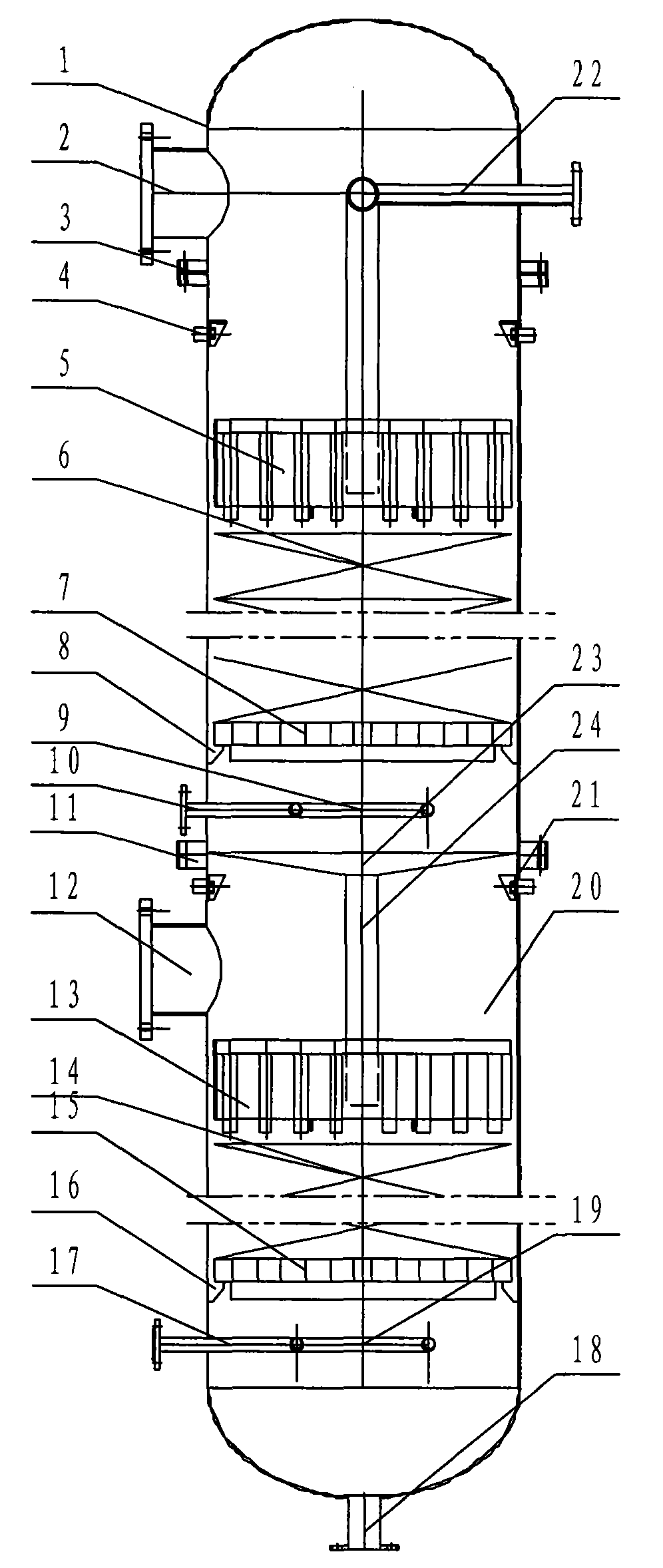

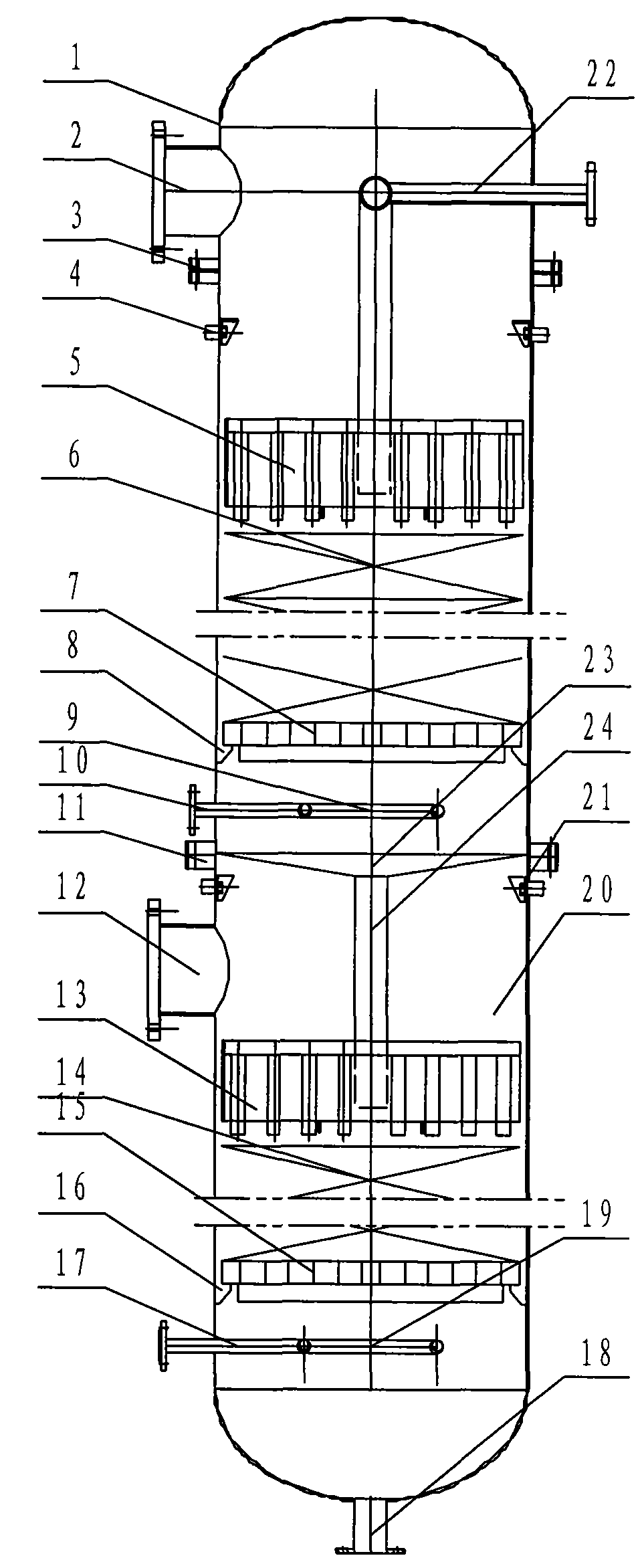

[0008] The present invention will be further described below in conjunction with accompanying drawing:

[0009] In the figure: 1. Upper tower body; 2. Upper vacuum pump interface; 3. Upper connecting flange; 4. Upper lifting lug; 5. Oil distribution plate; 6. Upper packing; 7. Upper packing frame; 8. Upper bracket ;9, upper direct steam injection pipe; 10, upper steam inlet pipe; 11, lower connecting flange; 12, lower vacuum pump interface; 13, lower oil distribution plate; 14, lower packing; 15, lower packing frame; 16, lower bracket 17, the lower steam inlet pipe; 18, the oil outlet pipe; 19, the lower direct steam injection pipe; 20, the lower tower body; 21, the lower lifting lug; 22, the oil inlet pipe;

[0010] A double-layer distillation tower, including a tower body, the tower body is composed of an upper tower body 1 and a lower tower body 20; an upper connecting flange 3 and a lower connecting flange 11 are arranged on the tower body, and an upper vacuum pump interfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com