Reaction gas transmission system

A technology of reaction gas and transmission system, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of high bending angle, hidden danger of operators and maintenance personnel, and metal fatigue, etc. The effect of reducing the possibility of gas leakage, easy maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

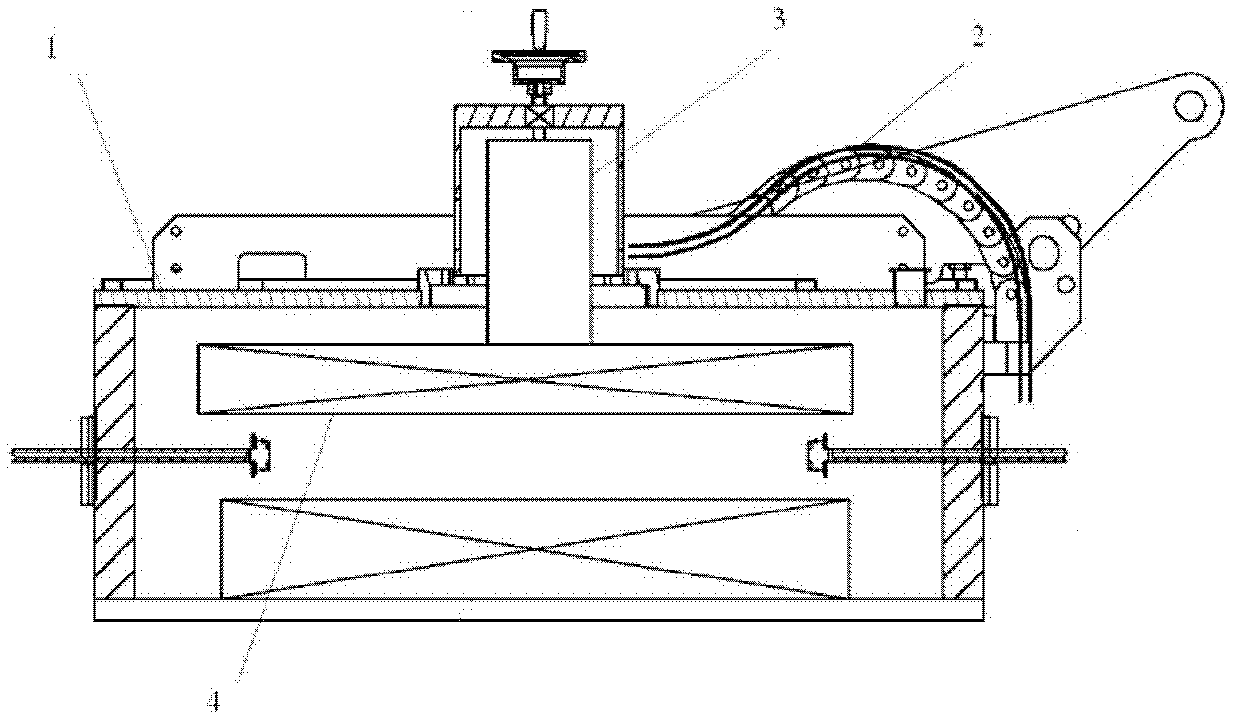

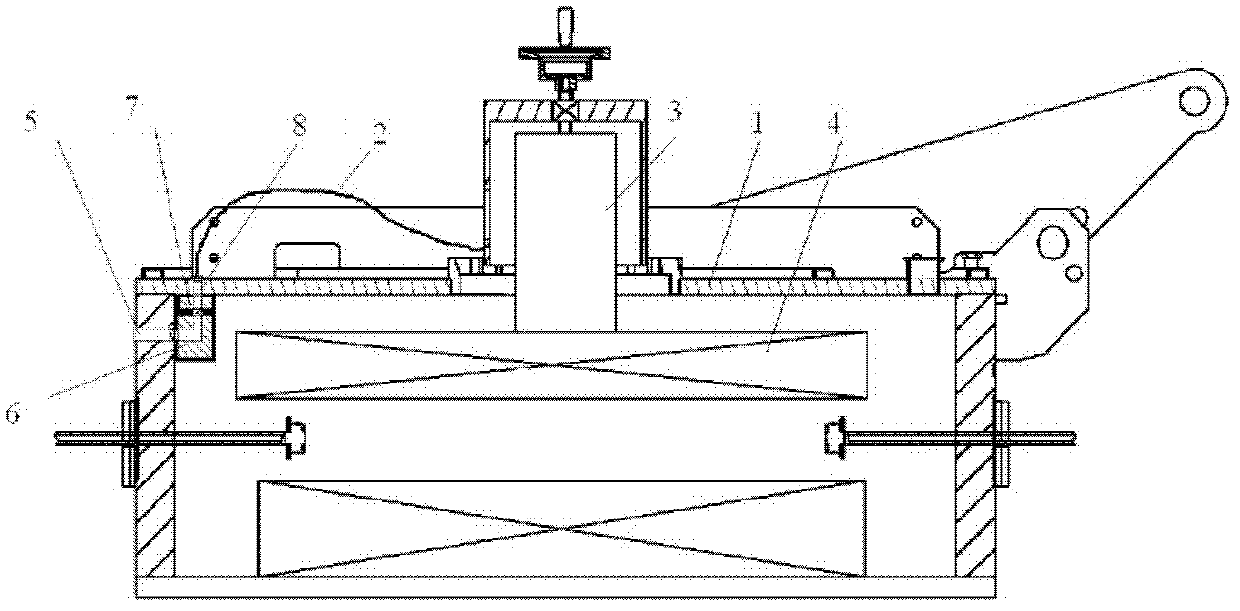

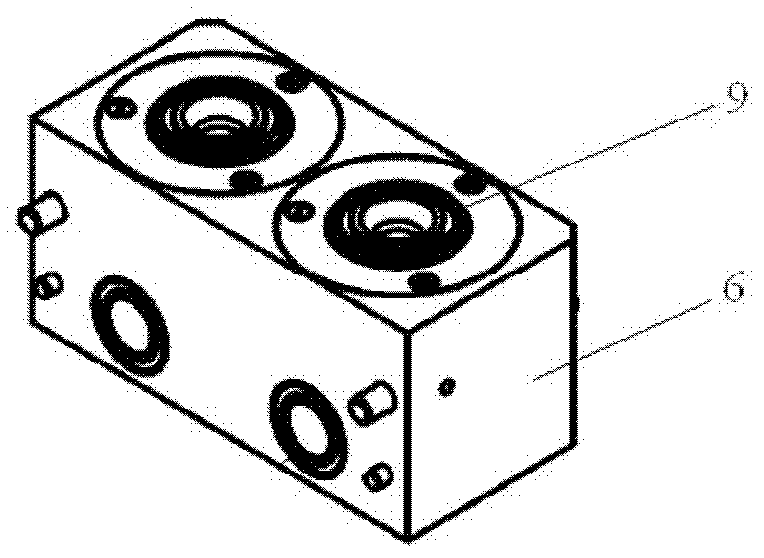

[0018] A reactive gas delivery system such as figure 2 As shown, it includes a flexible gas pipeline 2 located on the upper part of the reaction chamber cover 1, and the gas delivery end of the flexible gas pipeline 2 communicates with the spray device 4 in the reaction chamber through the cavity cover 1. Specifically, the flexible gas pipeline The gas delivery end of the road 2 communicates with the spray device 4 in the reaction chamber through the movable guide cylinder 3 on the chamber cover 1; the system also includes a gas introduction module 6 arranged on the inner side wall of the reaction chamber and a The gas export module 7 at the lower part of the chamber cover; the side wall of the reaction chamber has a through hole 5 for introducing gas, which is airtightly connected with the gas import module 6; the chamber cover 1 has a through hole 8 for extracting gas, the gas export module 7 and the flexible gas The air-introducing end of the pipeline 2 communicates throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com