Lightweight steel structure building wall

A technology for light steel structures and houses, which can be applied to walls, building components, building structures, etc., and can solve the problems of high pressure bearing performance requirements of load-bearing beams and columns, total weight, and reduced housing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings:

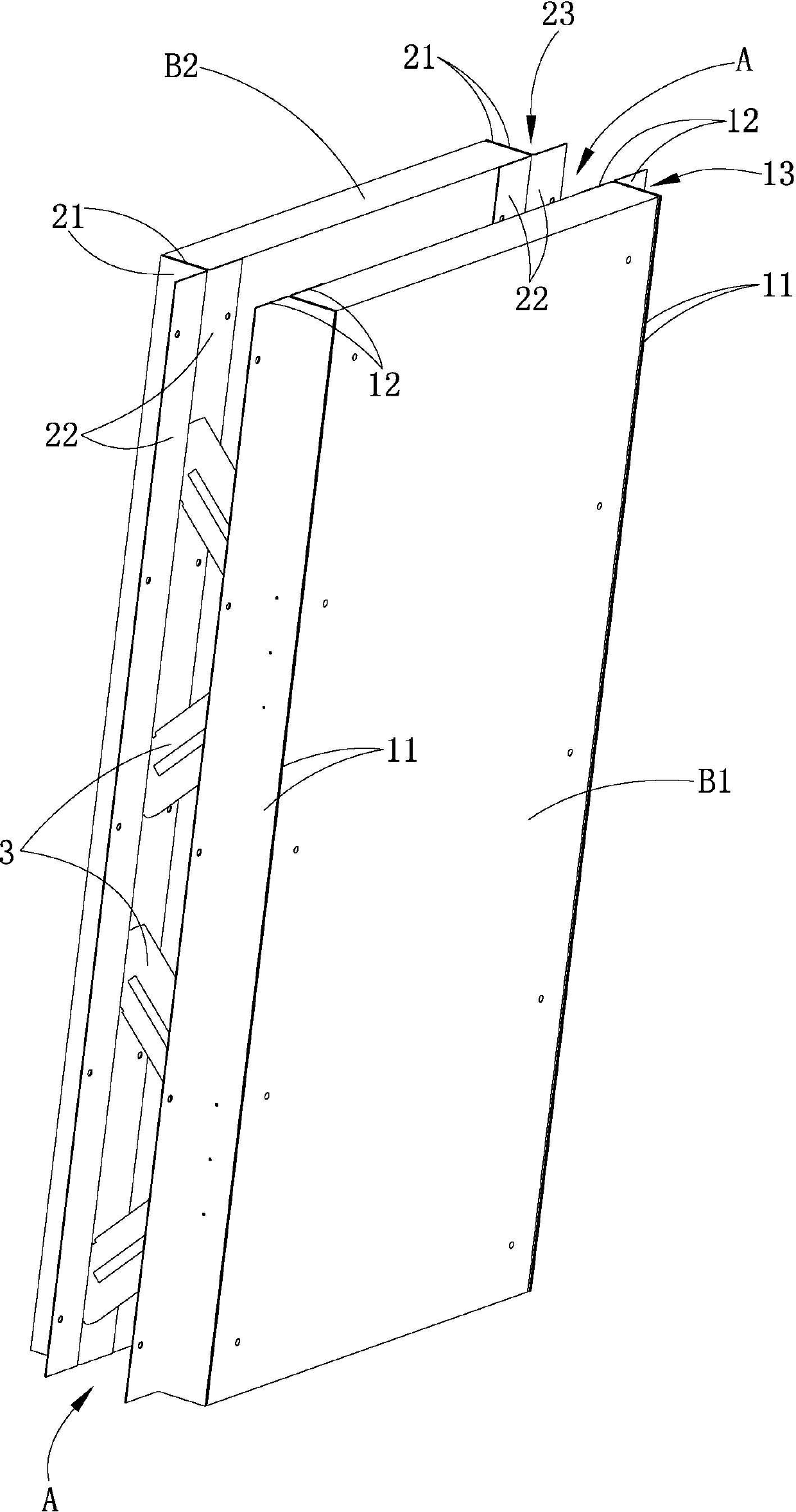

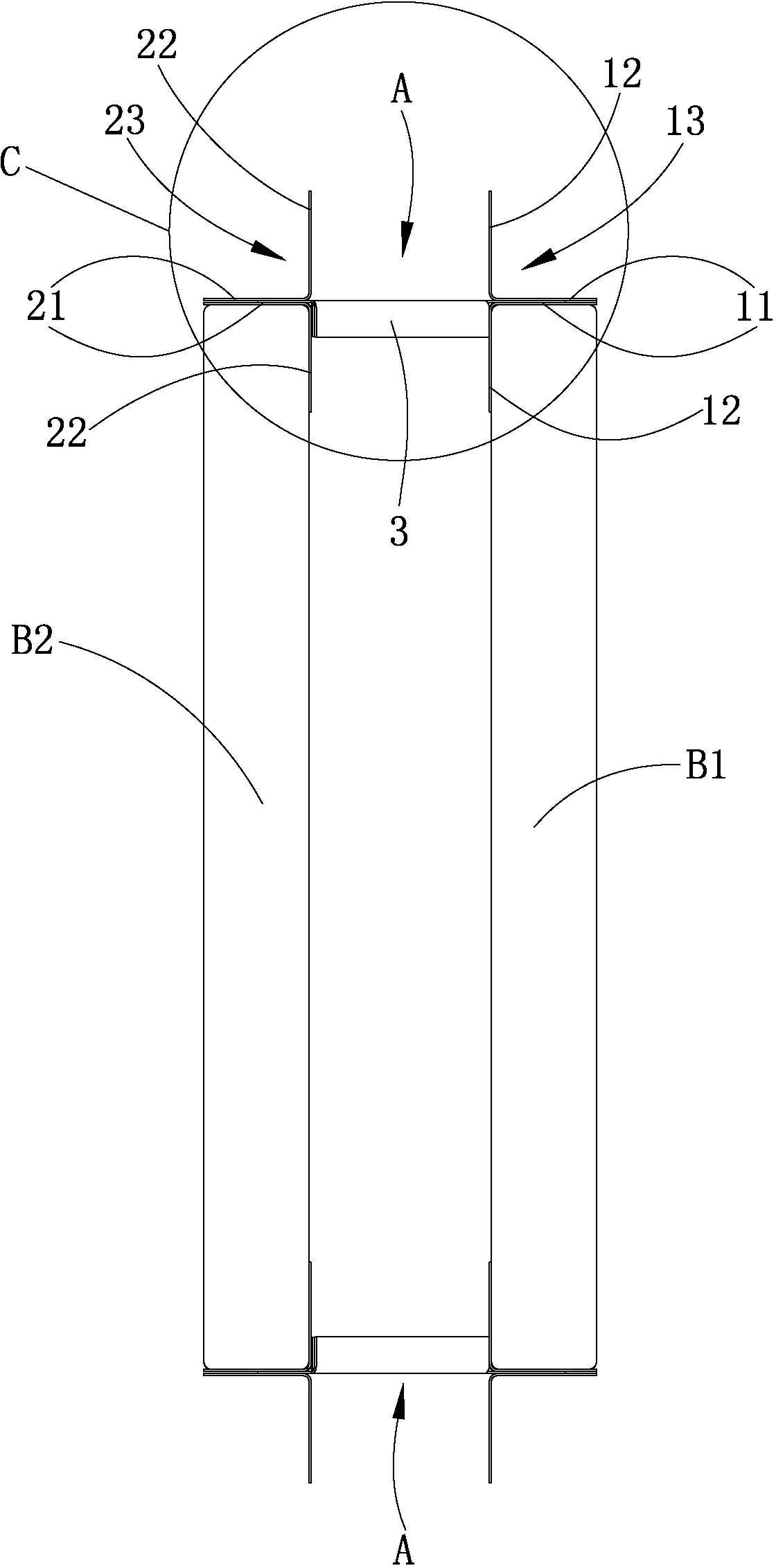

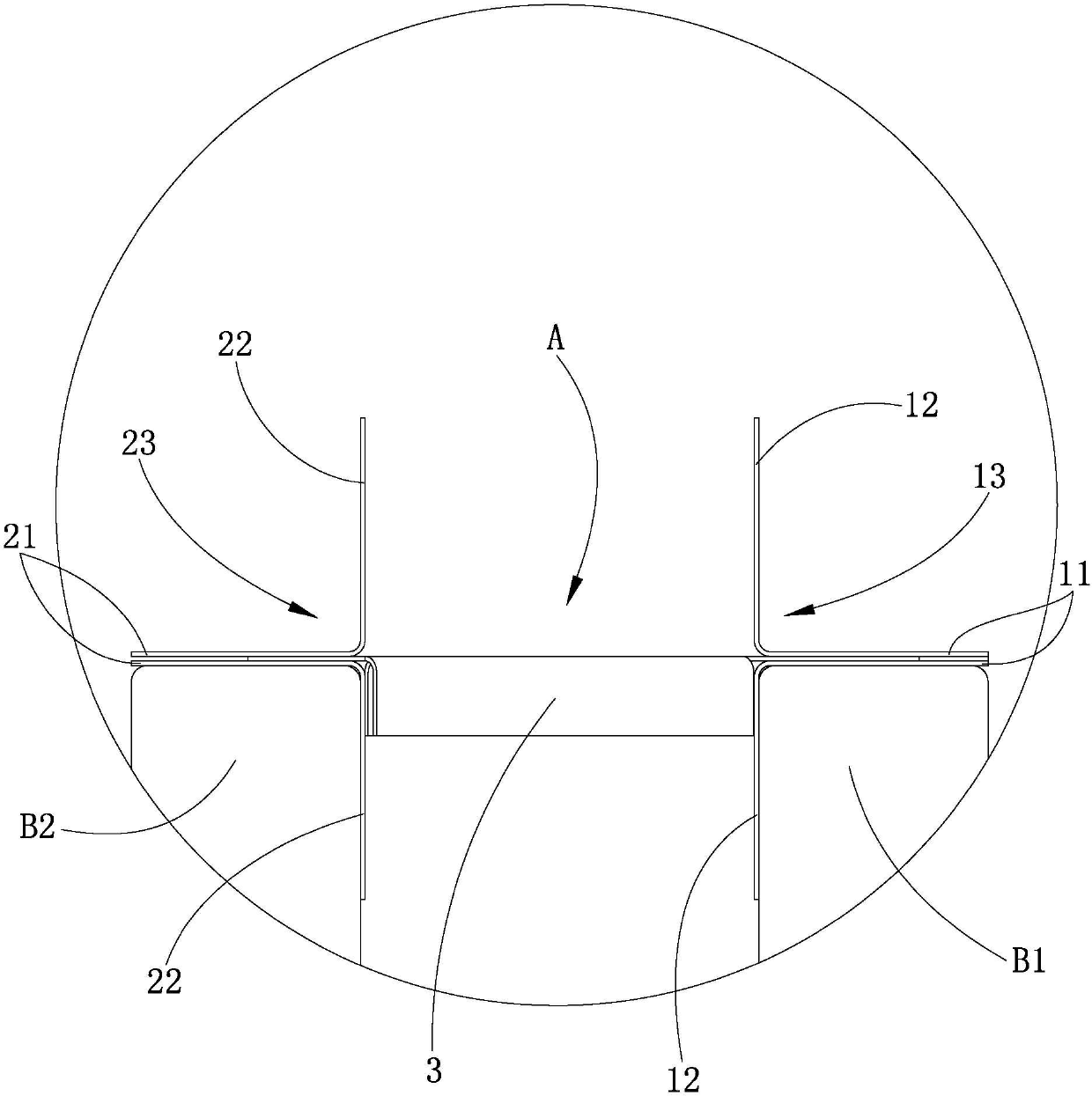

[0020] see figure 1 — image 3 :

[0021] The wall includes two vertical trusses A parallel to each other, a front side panel B1 connected between the front sides of the two trusses A, and a rear side panel B2 connected between the rear sides of the two trusses A;

[0022] Each truss A includes two vertical L-shaped first angle steels at the front side, two vertical L-shaped second angle steels at the rear side, and two horizontal V-shaped connector 3;

[0023] One vertical wing plate 11 in the two first angle steels is in close contact with the fastening screw, and the other vertical wing plate 12 in the two first angle steels is located near the rear side of the second angle steels and arranged symmetrically. An angle between the vertical wing plate 11 and the vertical wing plate 12 of an angle steel is a recess 13 with an included angle of 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com