Clutch controlling device

A technology of clutch control and clutch, which is applied in clutches, friction clutches, electric clutches, etc., can solve the problems of unadjustable separation cylinders that are not sufficiently reliable, have many components, complicated steps, and be careful enough, so as to improve the performance of assembly operations and Maintenance performance, maintenance control performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

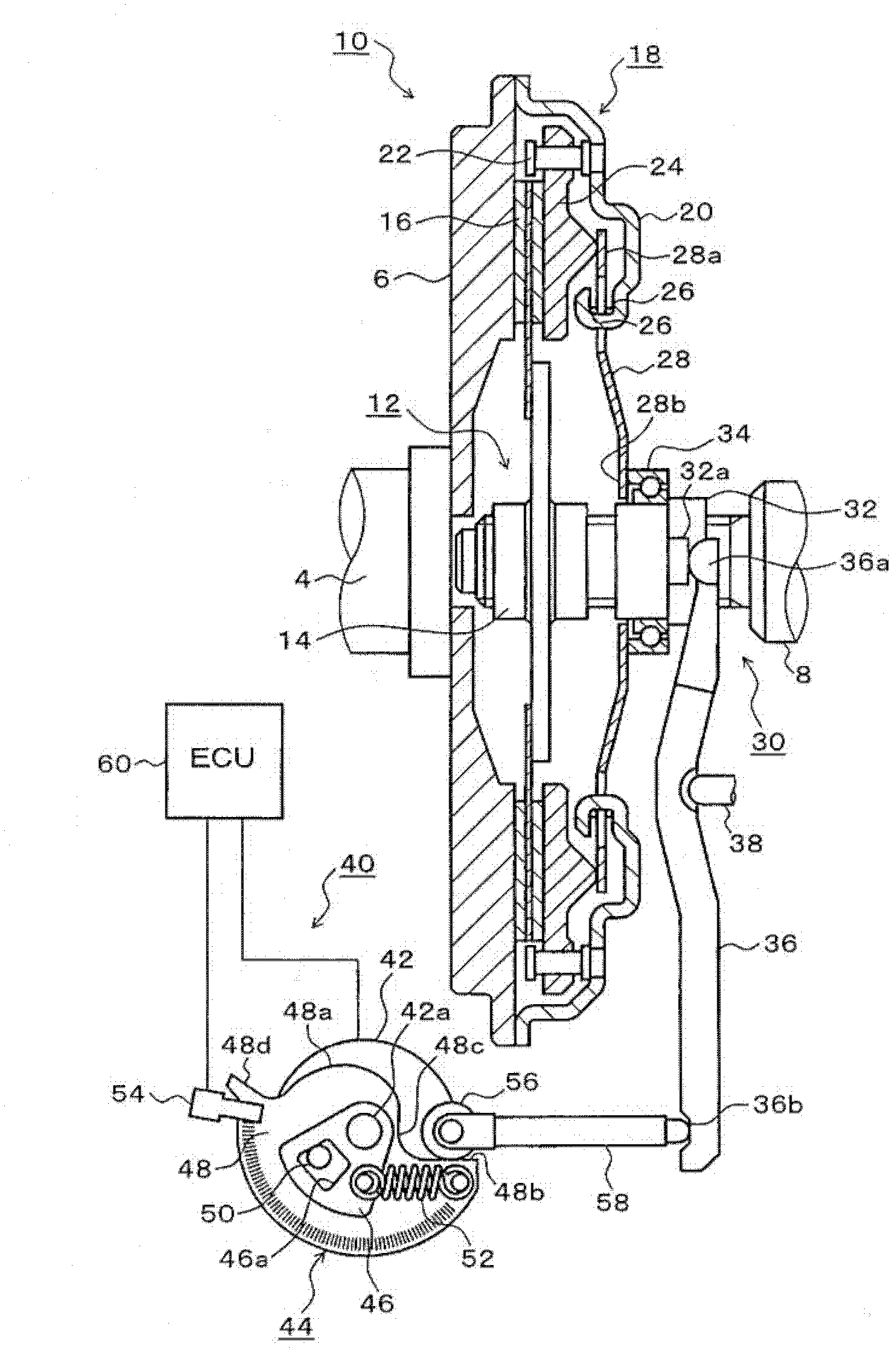

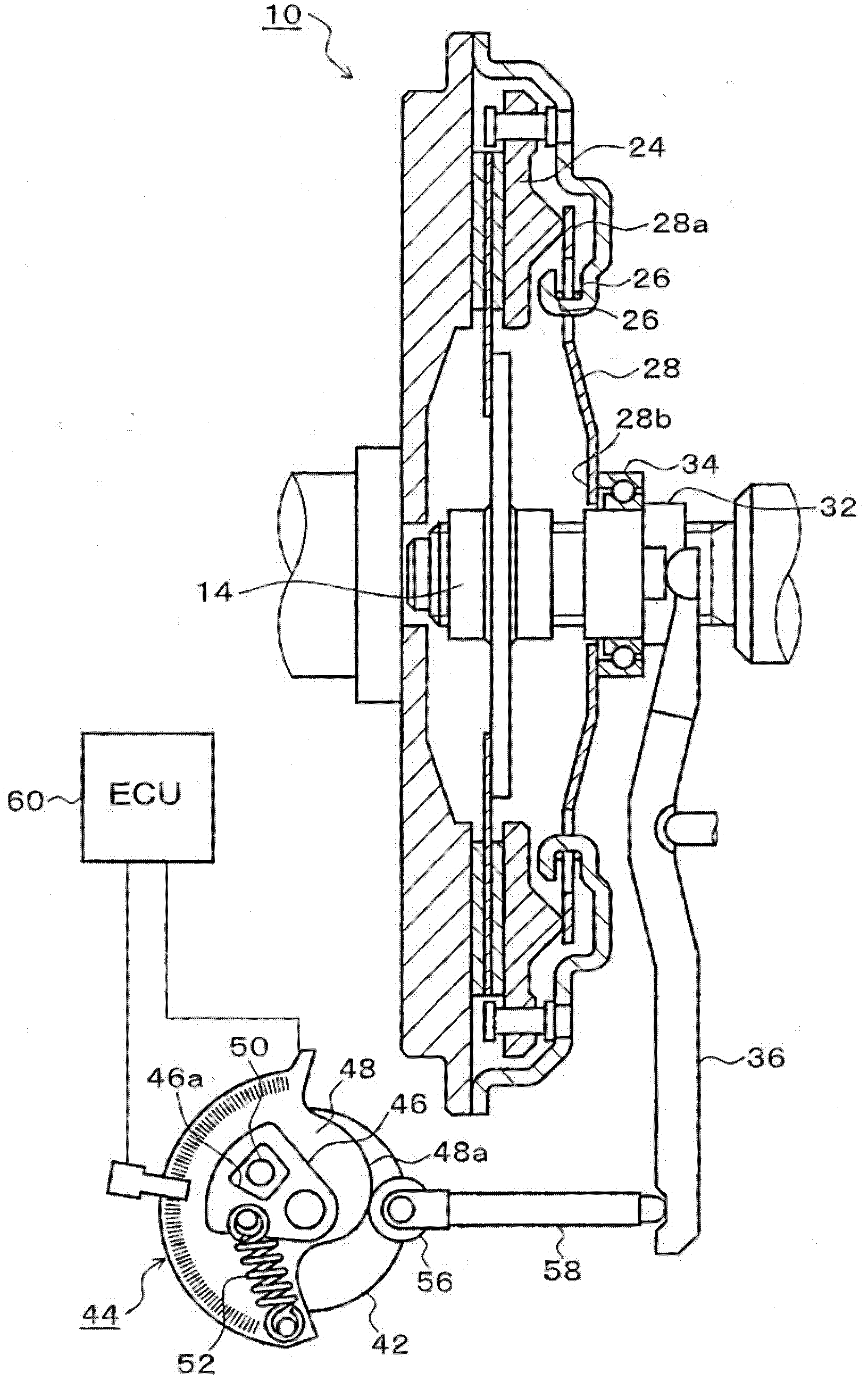

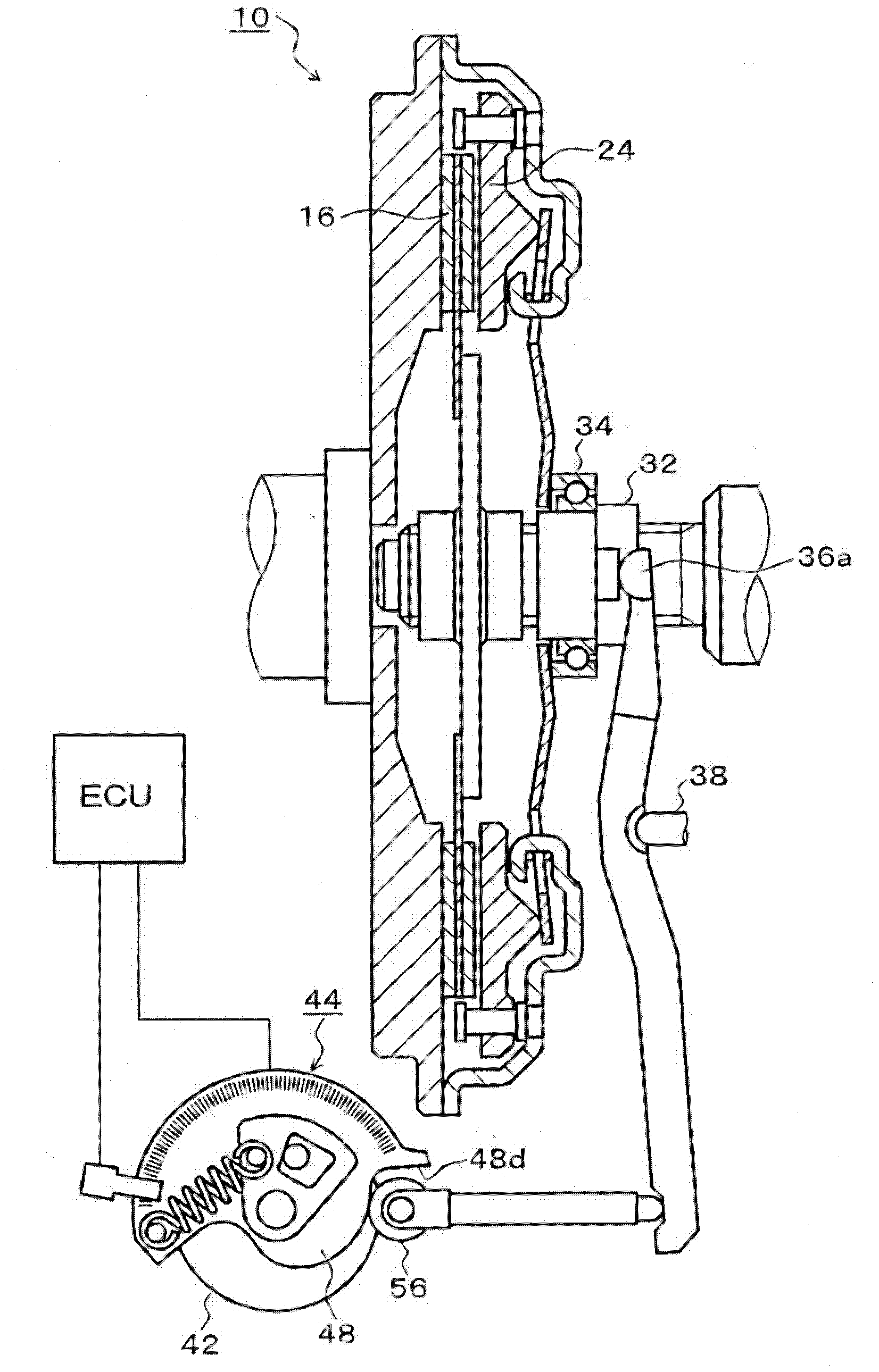

[0047] figure 1 It is an explanatory diagram showing an embodiment of a clutch provided with the clutch control device of the present invention, and shows a state in which the clutch is engaged when the clutch plate is a new product (not worn out).

[0048] exist figure 1 Among them, the clutch 10 is a device that cuts off or engages the torque transmission from the flywheel 6 that rotates together with the engine output shaft 4 to the transmission input shaft 8. and the clutch control device 40.

[0049] The clutch plate assembling part 12 has the clutch hub 14 splined to the end portion of the transmission input shaft 8 and the clutch disc 16 provided on the clutch hub 14, and the clutch plate assembling part 12 can be moved along the axial direction of the transmission input shaft 8. Advance and retreat movements.

[0050] The clutch cover assembly part 18 has: a clutch cover 20 that rotates integrally with the flywheel 6; a pressure plate 24 that can move in the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com