Testing apparatus used for researching dissected sintering process, and application method thereof

A test device and sintering process technology, applied in the field of metallurgical sintering, to achieve the effect of intuitive and comprehensive research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

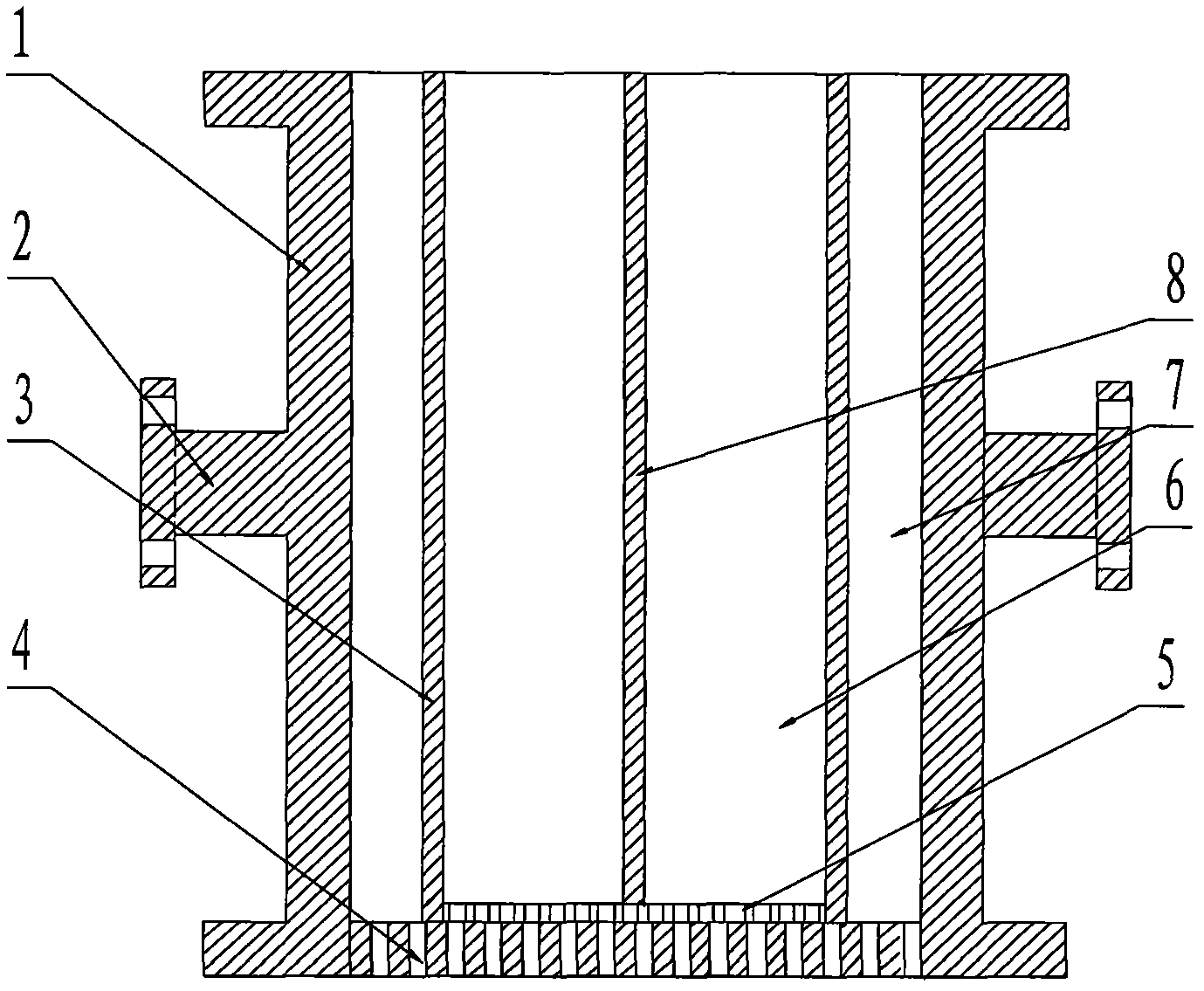

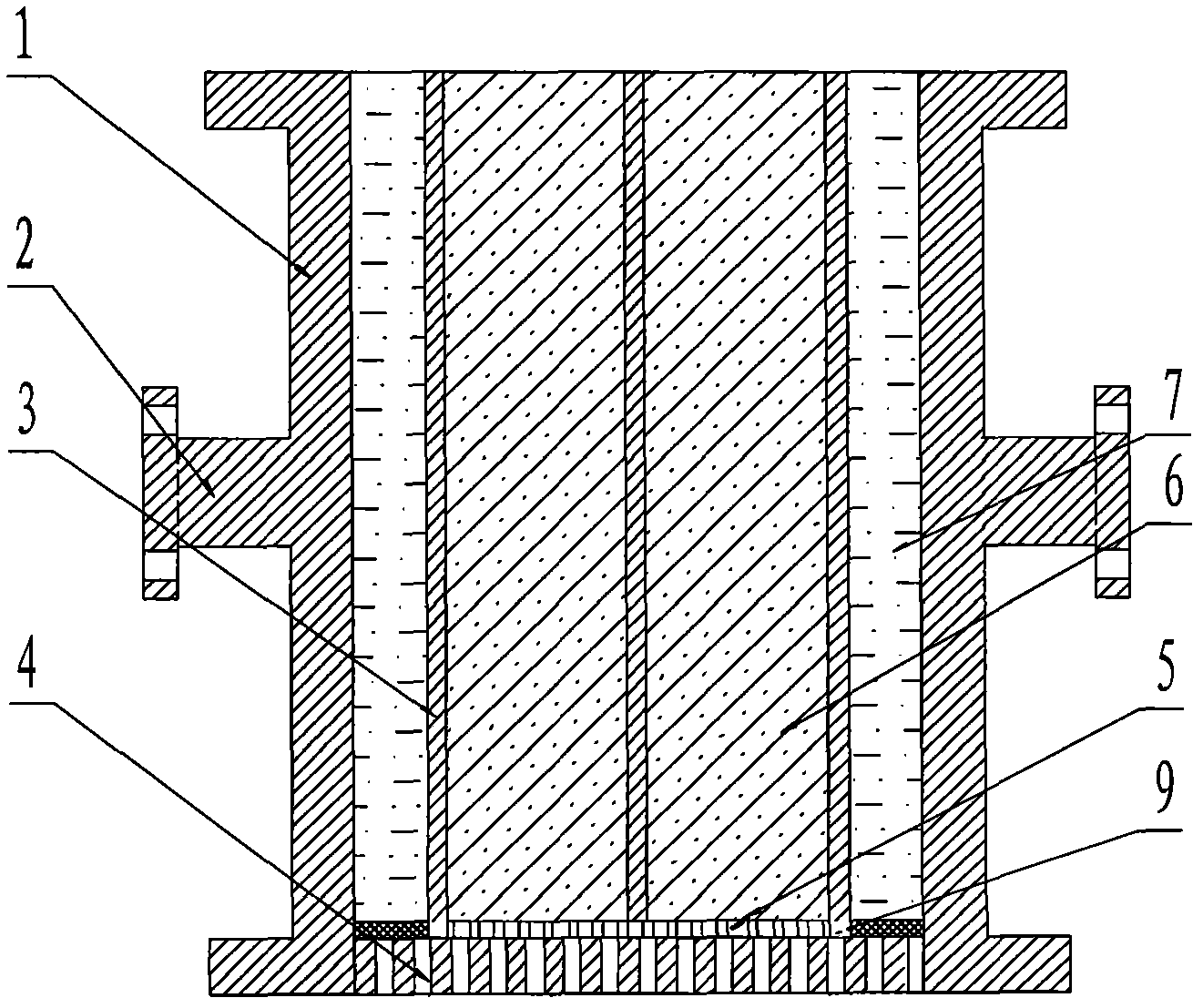

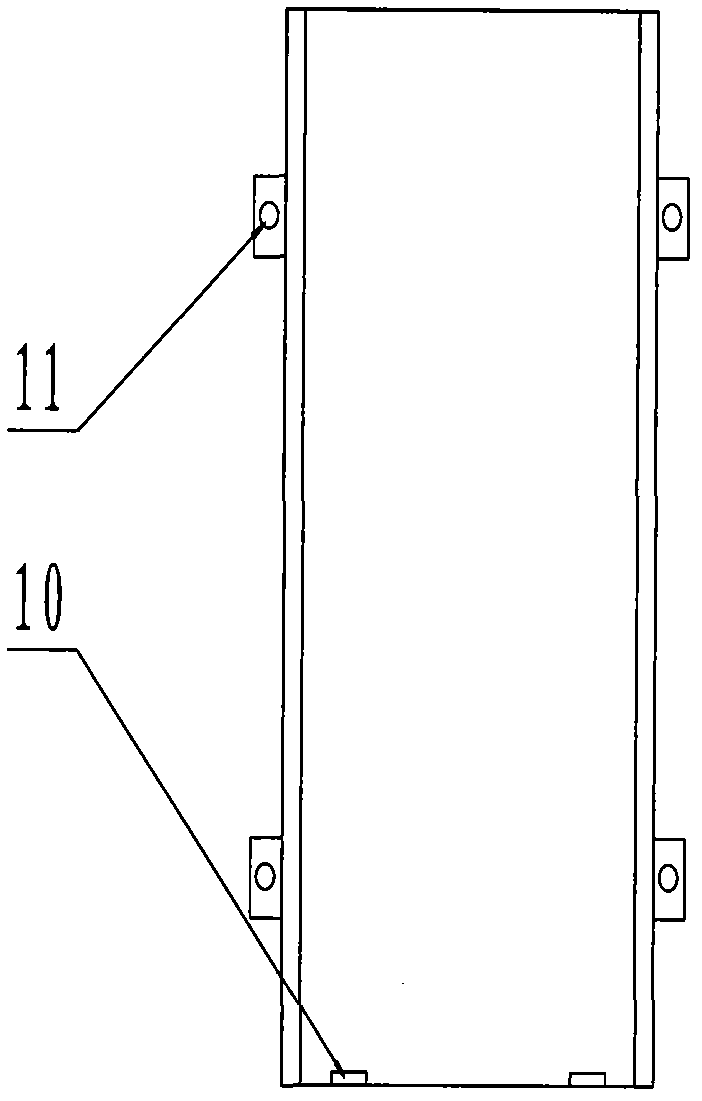

[0028] A test device for studying the anatomical sintering process, including a sintering cup body 1, characterized in that: a cylindrical sleeve 3 is built on the grate bar 4 in the sintering cup body 1, and the cylindrical sleeve 3 is two semi-cylindrical The upper and lower parts of the butt joint ribs of two semi-cylindrical sleeves are respectively provided with two sleeve fastening clips 11, which are connected by bolts and nuts to form an integral cylindrical sleeve 3, the cylindrical sleeve The height of the cylinder 3 is that after being placed on the grate bar 4 in the sintering cup body, it is flush with the sintering cup, and a rectangular partition 8 is arranged in the middle of the cylindrical sleeve, and the bottom of each semi-cylindrical sleeve is symmetrical. Support ears 10 are set, sleeve grate bars 5 are placed on support ears 10, and sleeve fire grate bars 5 are in the same direction as fire grate bars 4 in the sintering cup.

[0029] The outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com