Composite primary reflector supporting device for large telescope

A primary reflector and composite support technology, applied in telescopes, installations, optics, etc., can solve the problems of affecting the imaging quality and the large influence of the main reflector's surface deformation, so as to improve the imaging quality and reduce the surface change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

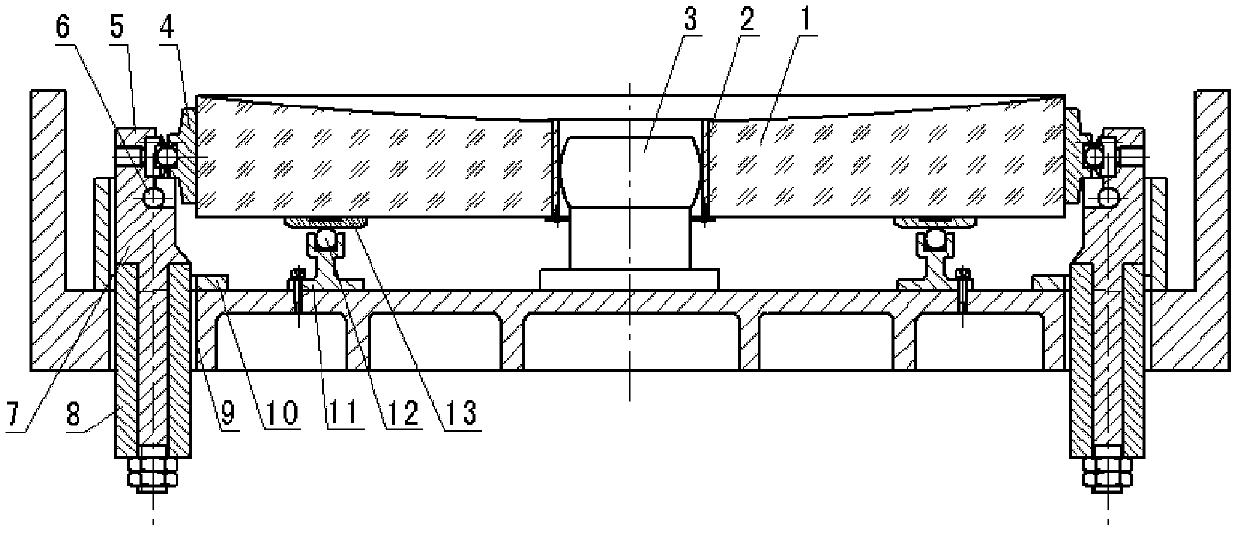

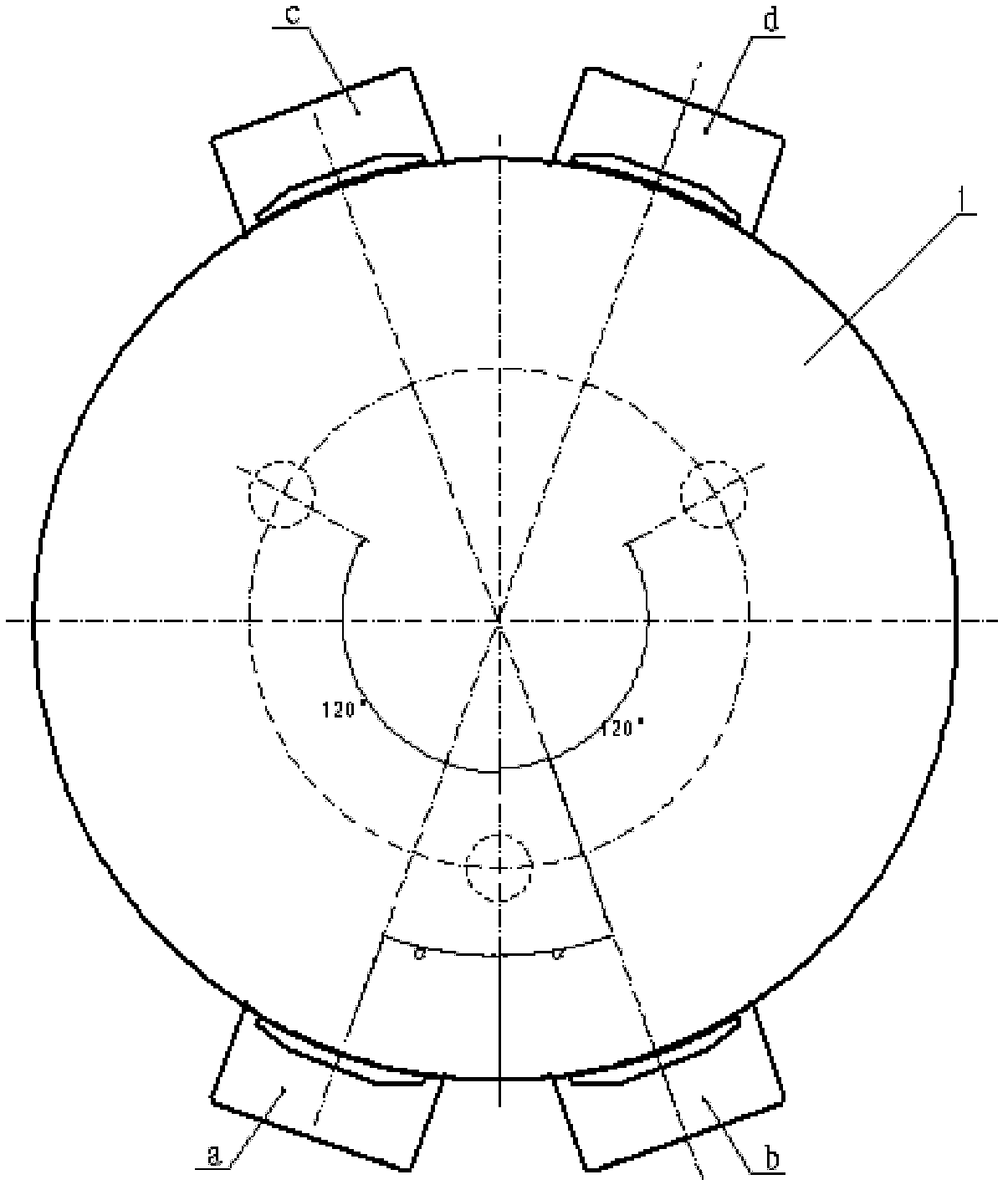

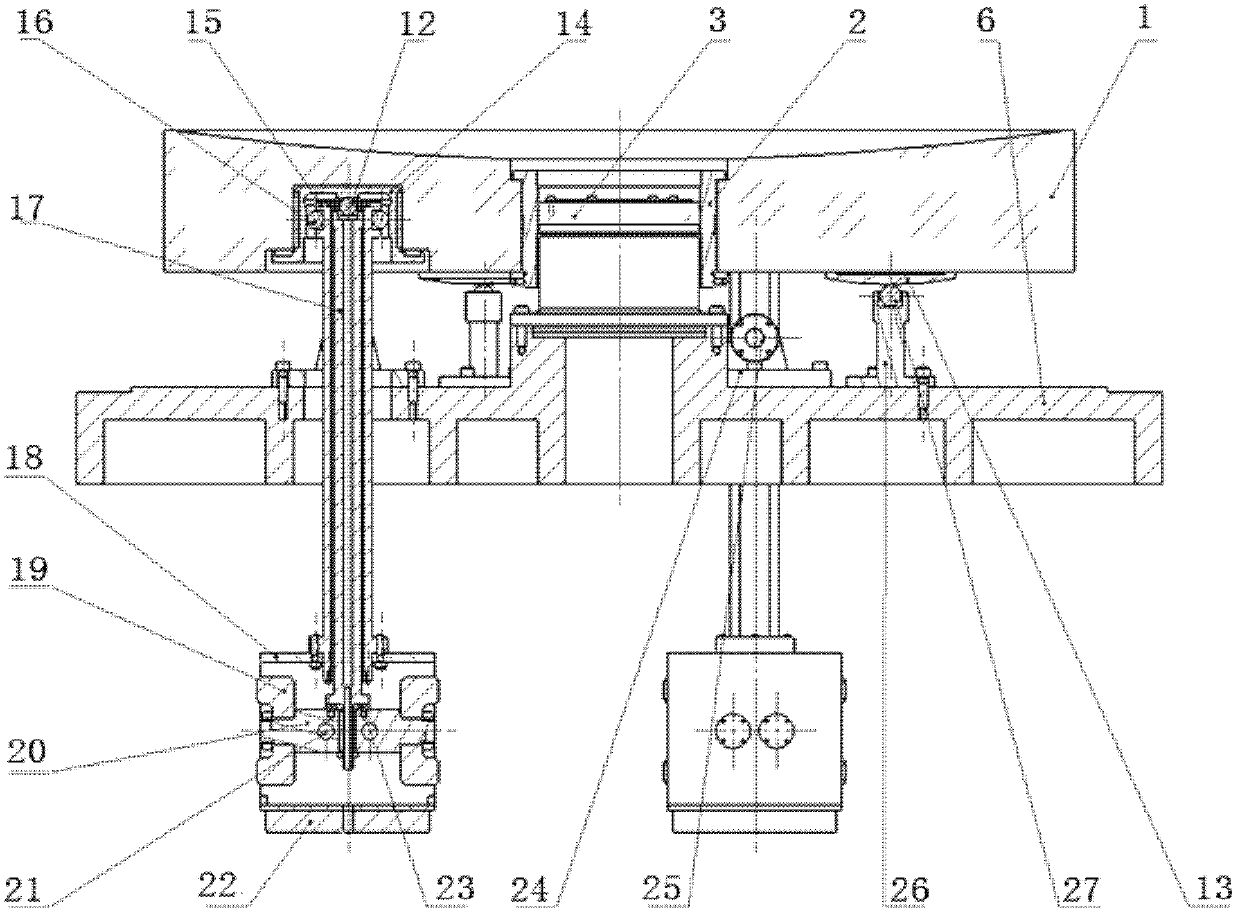

[0016] combine image 3 and Figure 4 Describe this embodiment, a composite support device for the main reflector of a large telescope, the device includes a main reflector 1, a support base part, a fixed back support part and a radial and back composite support part. The support base part includes base 6, central positioning shaft 3, center hole bushing 2; the fixed back support part includes back support seat 26, support steel ball 27, back support disc 13; the radial and back composite support parts are divided into radial A floating support mechanism and a back floating support mechanism, the radial floating support mechanism includes a bushing 14, a radial support rod 15, a radial support steel ball 16, a counterweight box 18, a radial counterweight 22, a support frame 24 and a diameter To support fixed shaft 25;

[0017] The support of the large primary mirror 1 described in this embodiment may include three fixed back support parts and several radial and back composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com