Gas switch

A gas switch and electrode technology, applied in the field of gas switches, can solve the problems of increasing maintenance costs, affecting the service life of gas switch conduction performance, and triggering uneven ablation of electrodes, so as to prolong service life, avoid conduction performance decline, Guaranteed the effect of breakdown and conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

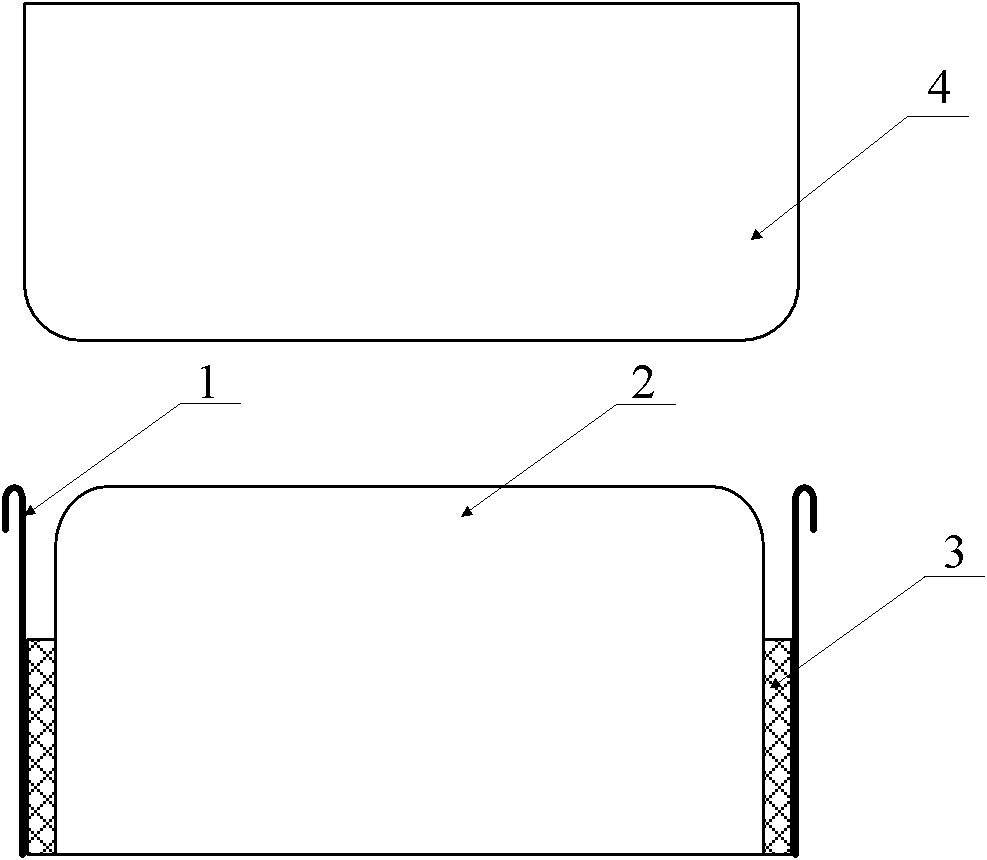

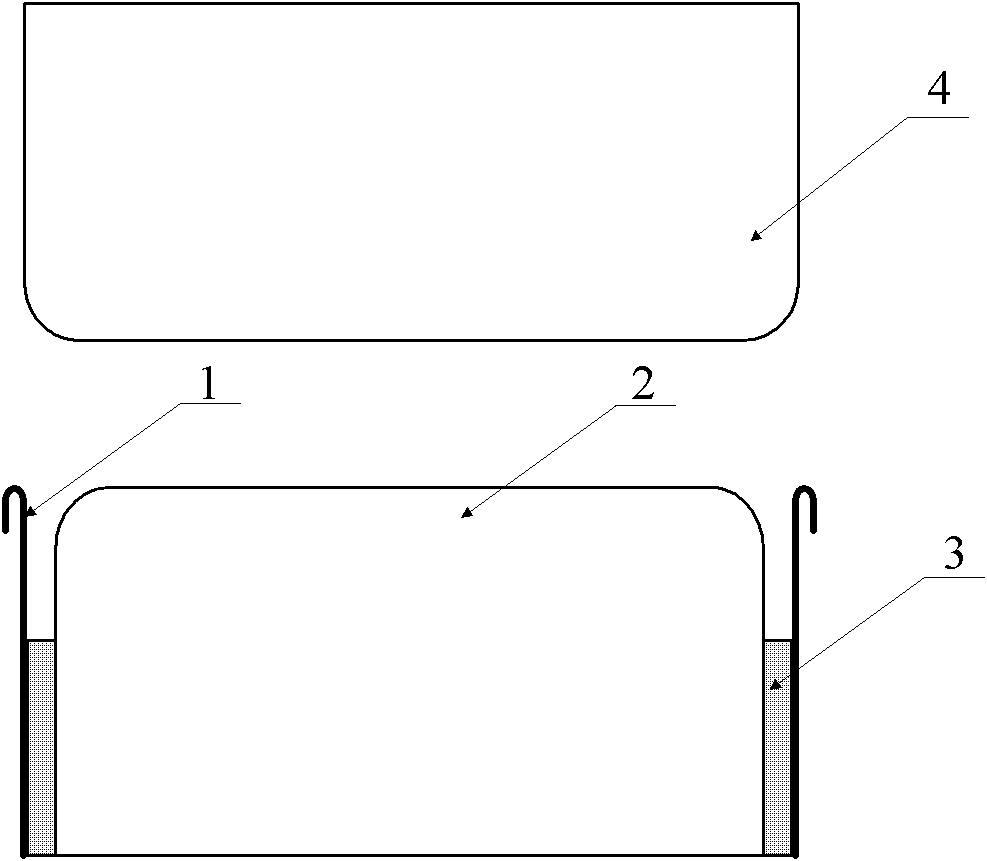

[0022] Such as figure 1 , figure 2 As shown, the gas switch of the present invention includes a metal sleeve 1 , a lower electrode 2 , an insulating sleeve 3 and an upper electrode 4 .

[0023] The upper electrode 4 and the lower electrode 2 are made of high-density graphite material and arranged axially symmetrically.

[0024] The lower part of the upper electrode 4 and the upper part of the lower electrode 2 are rounded so that an approximately uniform electric field is formed between the upper electrode 4 and the lower electrode 2 to effectively prevent electric field distortion.

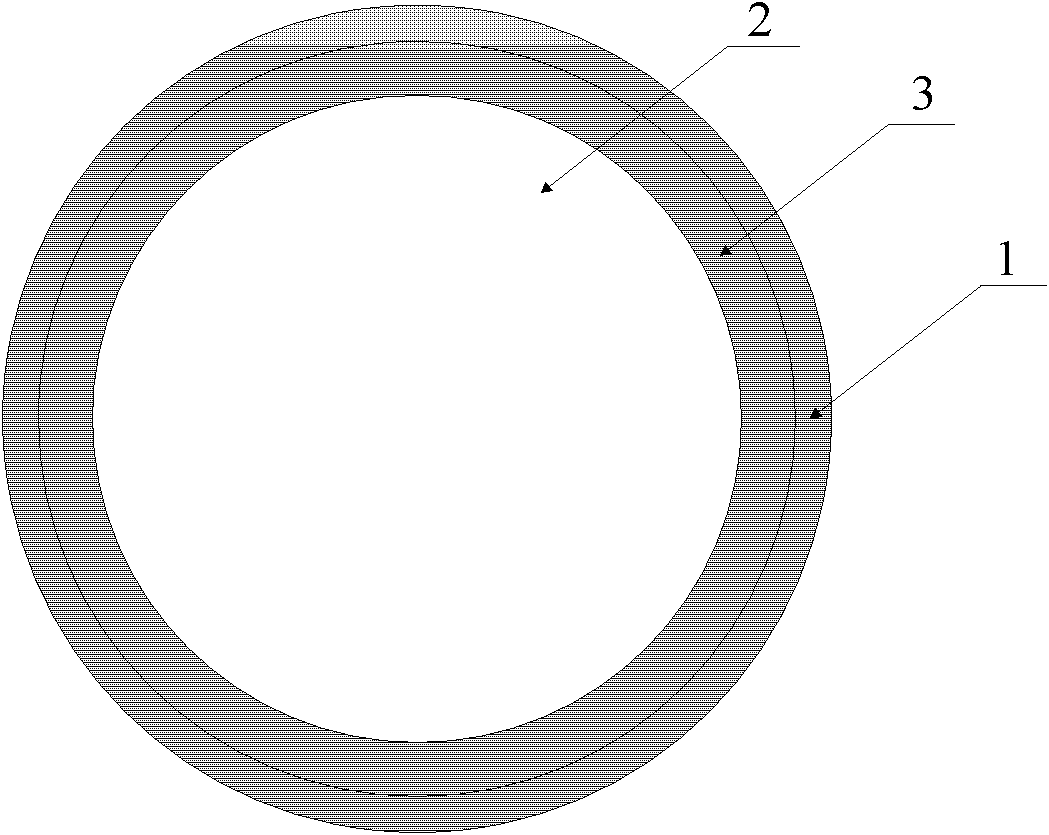

[0025] The insulating sleeve 3 is tightly sleeved on the outside of the lower electrode 2 , and the height of the insulating sleeve 3 is smaller than that of the lower electrode 2 .

[0026] The metal sleeve 1 is tightly fitted on the outside of the insulating sleeve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com