Method for manufacturing element for belt of continuously variable transmission

A technology of continuously variable transmission and manufacturing method, which is applied in the direction of household components, applications, belts, etc., can solve the problems of increased manufacturing cost, high manufacturing cost, etc., achieve the effect of smooth flow and save the taper forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0052] Embodiments of the present invention will be described based on the drawings.

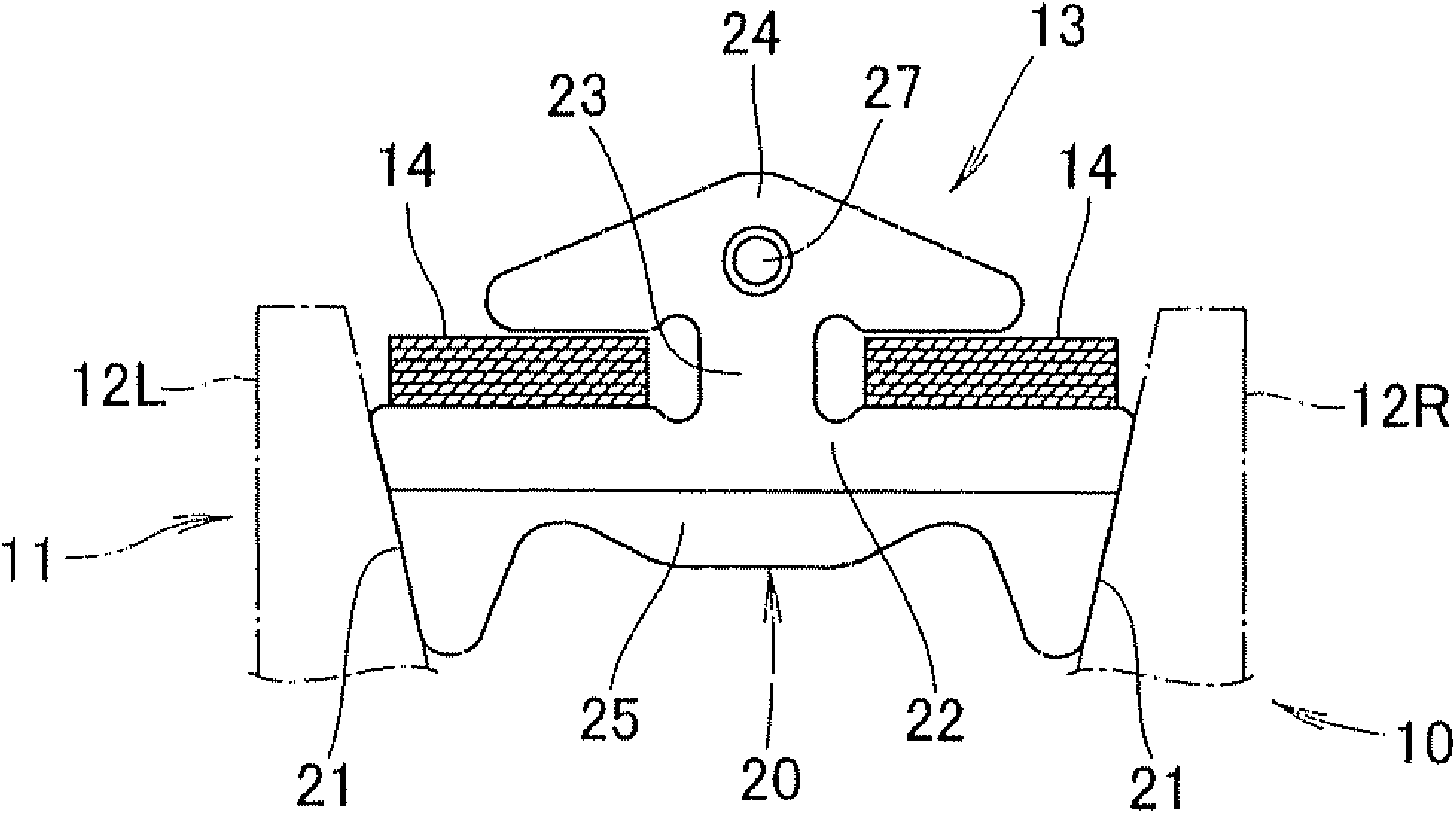

[0053] like figure 1 As shown, a continuously variable transmission (CVT) 10 mainly includes a pair of pulleys 11 (only one is shown) and a belt 13 wound around the pulleys 11 .

[0054] The belt 13 includes: laminated rings 14 , 14 formed by overlapping annular metal rings; and elements 20 supported by the laminated rings 14 , 14 .

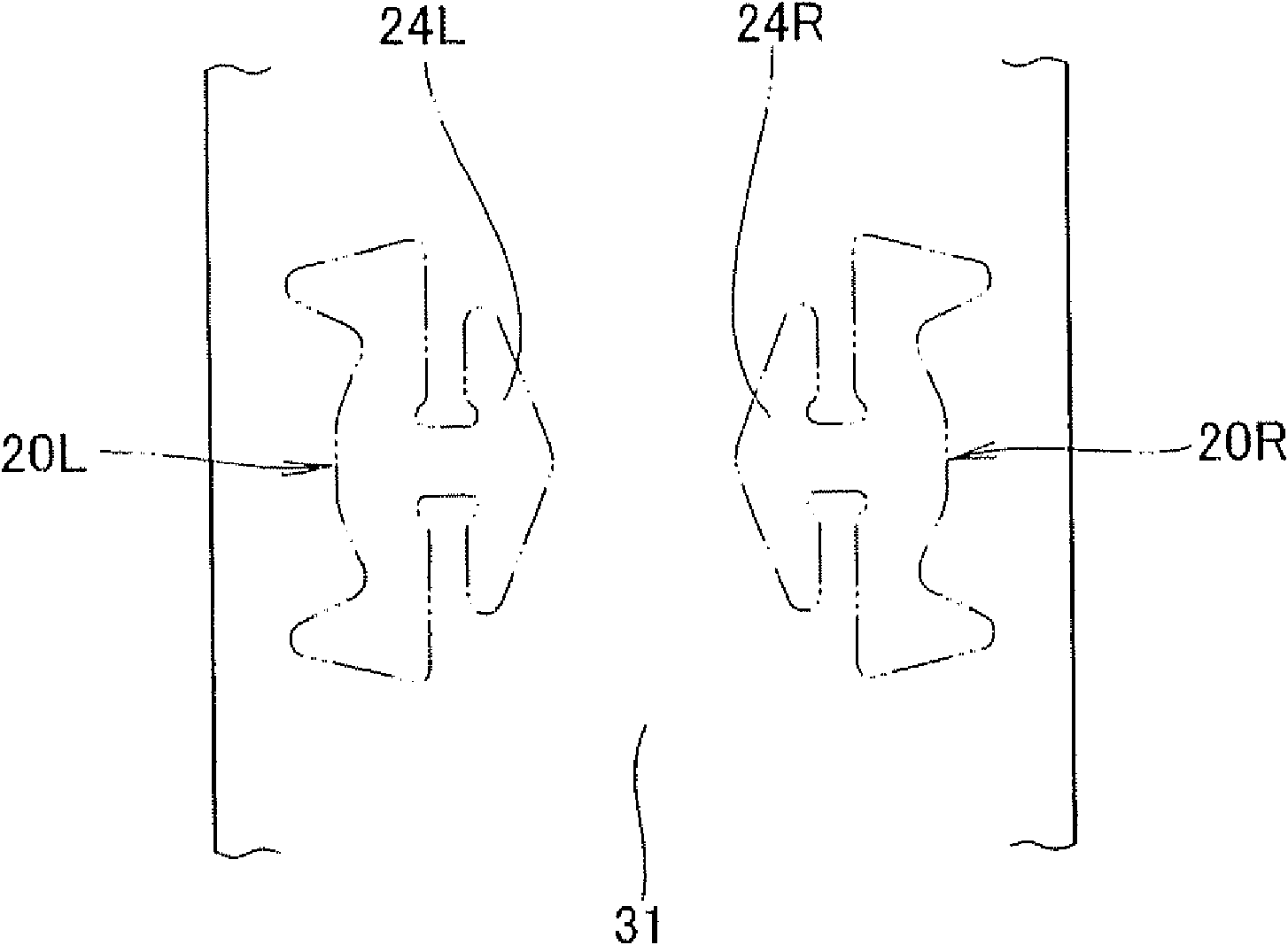

[0055] The element 20 includes: a horizontally long main body 22 having left and right sides 21 , 21 abutting on left and right halves 12L, 12R of the pulley 11 ; and a narrow neck extending upward from the main body 22 . 23 ; a triangular-shaped head 24 provided on the upper part of the neck 23 .

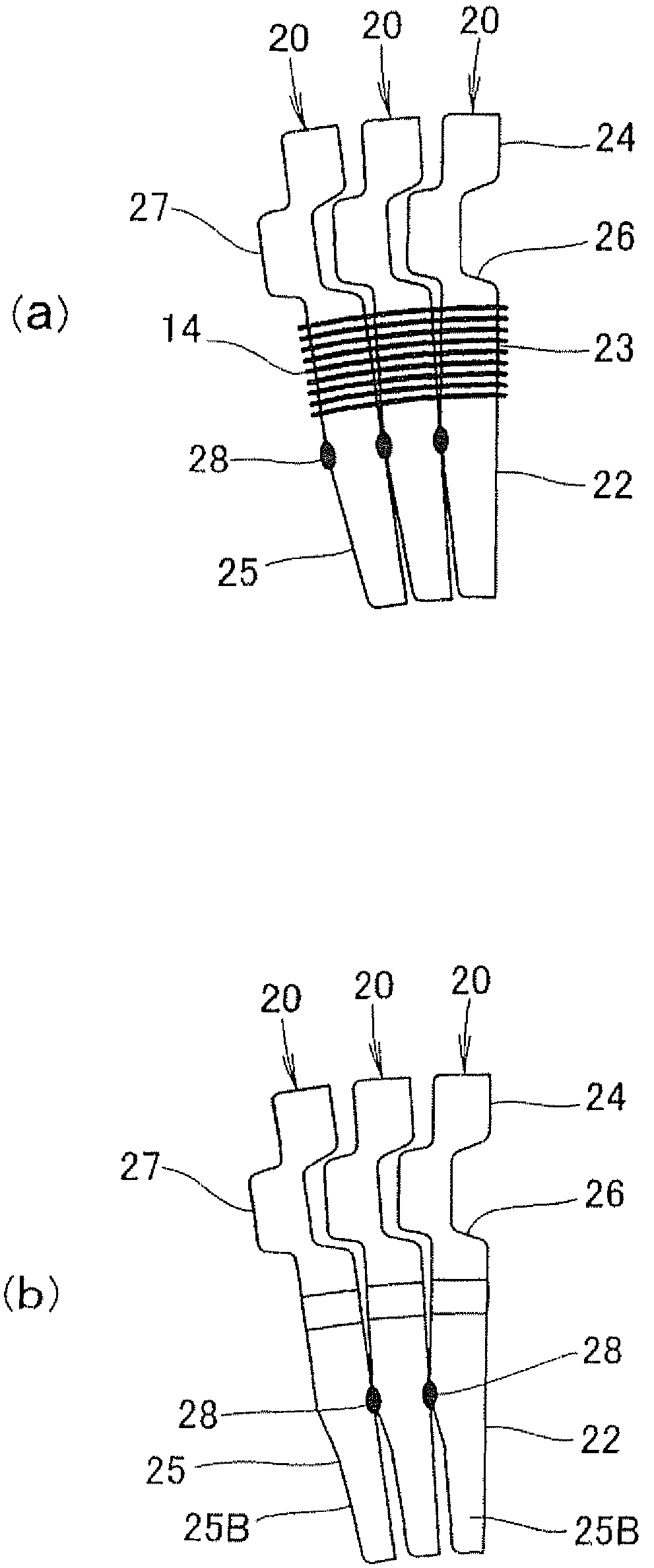

[0056] like figure 2 As shown in (a), the main body portion 22 has a tapered portion 25 tapering downward, and the head portion 24 has a hole 26 and a complemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com