Cutting tool

A technology of cutting tools and reciprocating rods, which is applied in the direction of manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve the problems of low speed, large knife mark distance, and low surface accuracy, so as to speed up the feed and improve the cutting efficiency. The effect of improving accuracy and reciprocating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

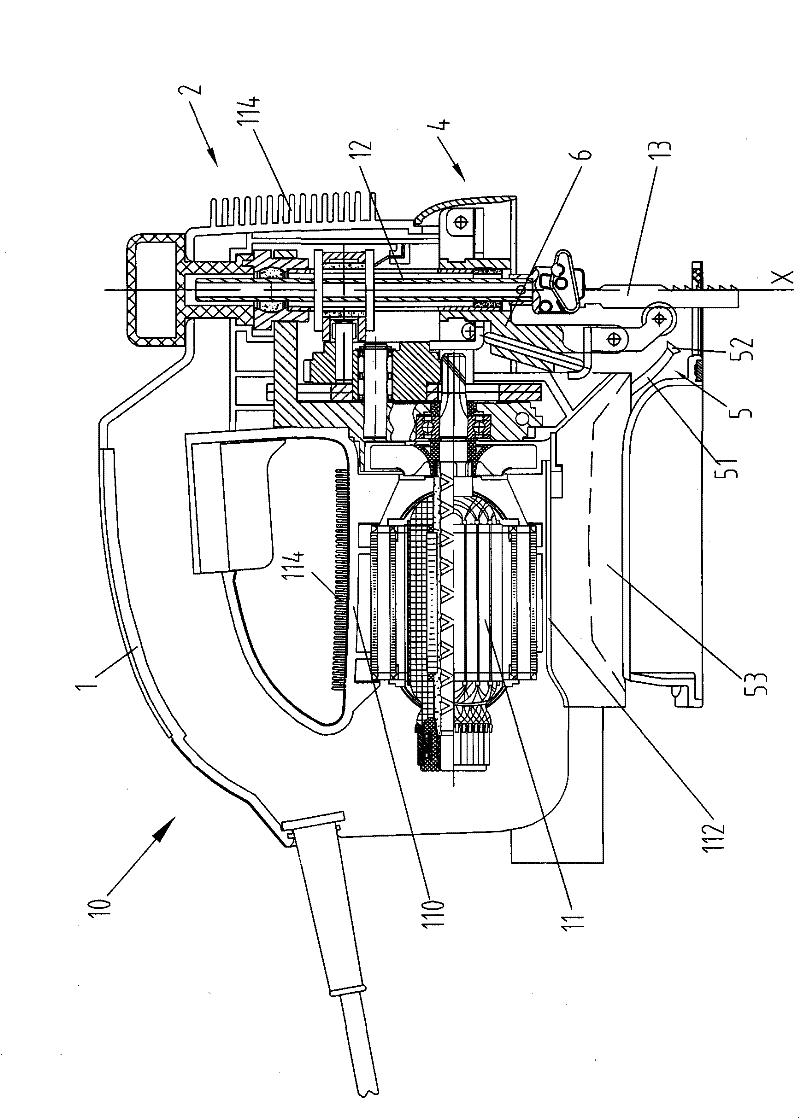

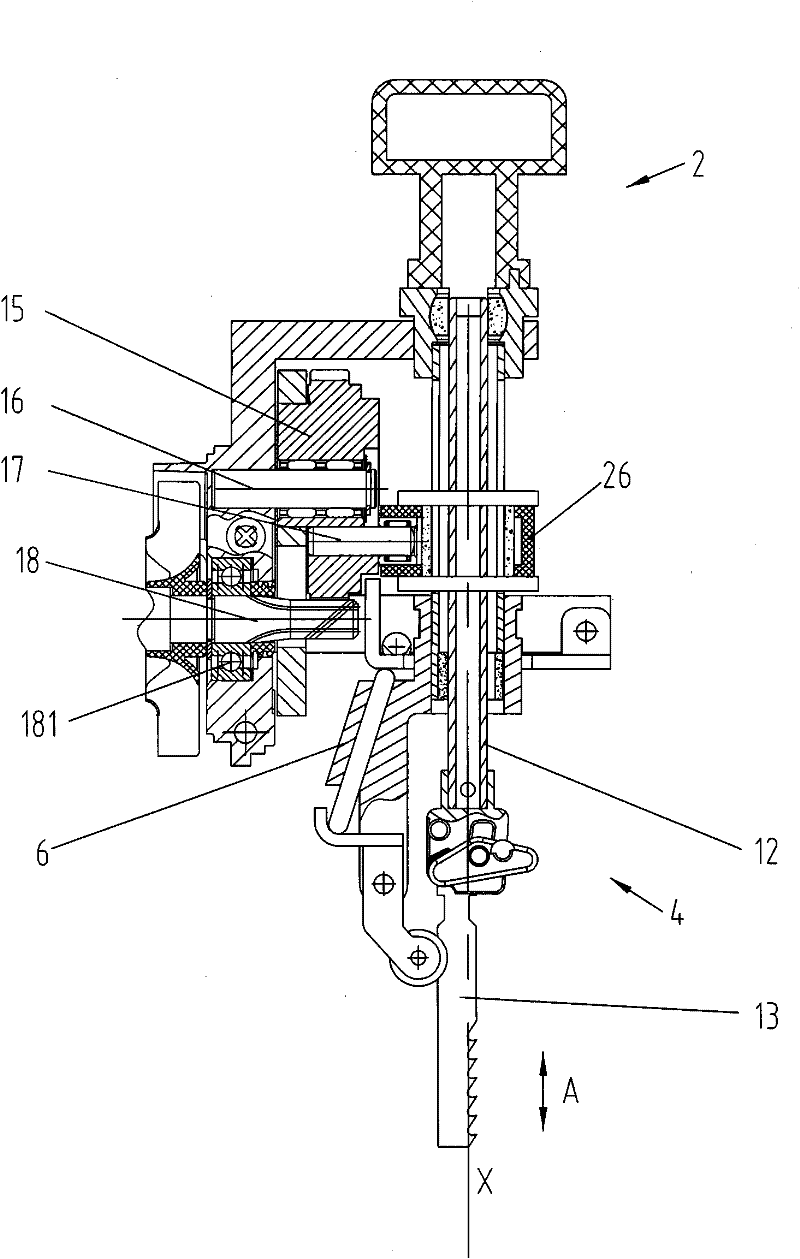

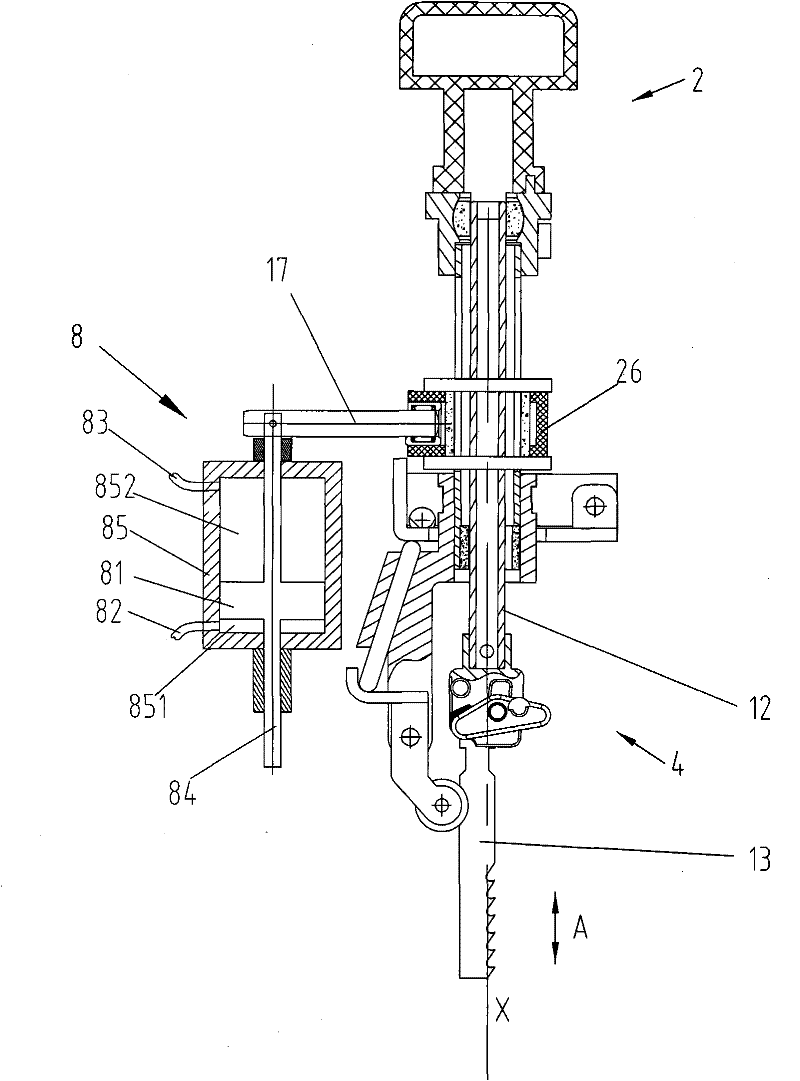

[0033] Such as figure 1 As shown, the present invention discloses a cutting tool, especially a reciprocating cutting tool, especially a jigsaw 10 . The jigsaw 10 includes a housing 1, and a power source is arranged in the housing 1. In this preferred embodiment, the power source is a motor 11. For convenience, the part of the housing 1 that accommodates the motor 11 is called the motor housing 110. . A reciprocating rod 12 that can be driven by a motor is provided at the front of the housing 1 , and the reciprocating rod has an axis X; a saw blade 13 is connected to the lower end of the reciprocating rod 12 . Housing 1 is also provided with a rotary drive mechanism 2 that can rotate the saw blade 13 and a knife lift drive mechanism 4 that can swing the saw blade 13. 2, the saw blade 13 can be rotated to obtain the required cutting angle; the rotary drive mechanism 2 can also rotate the saw blade 13 to obtain a wave-line cutting track; the knife-lifting drive mechanism 4 can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com