Exhaust pipe milling small-flange clamp

A technology for exhaust pipes and flanges, which is applied in the field of small flange fixtures for exhaust pipe milling. It can solve the problems of flange installation difficulties, large errors, and workpiece installation axis offsets, and achieve the effect of avoiding position offsets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

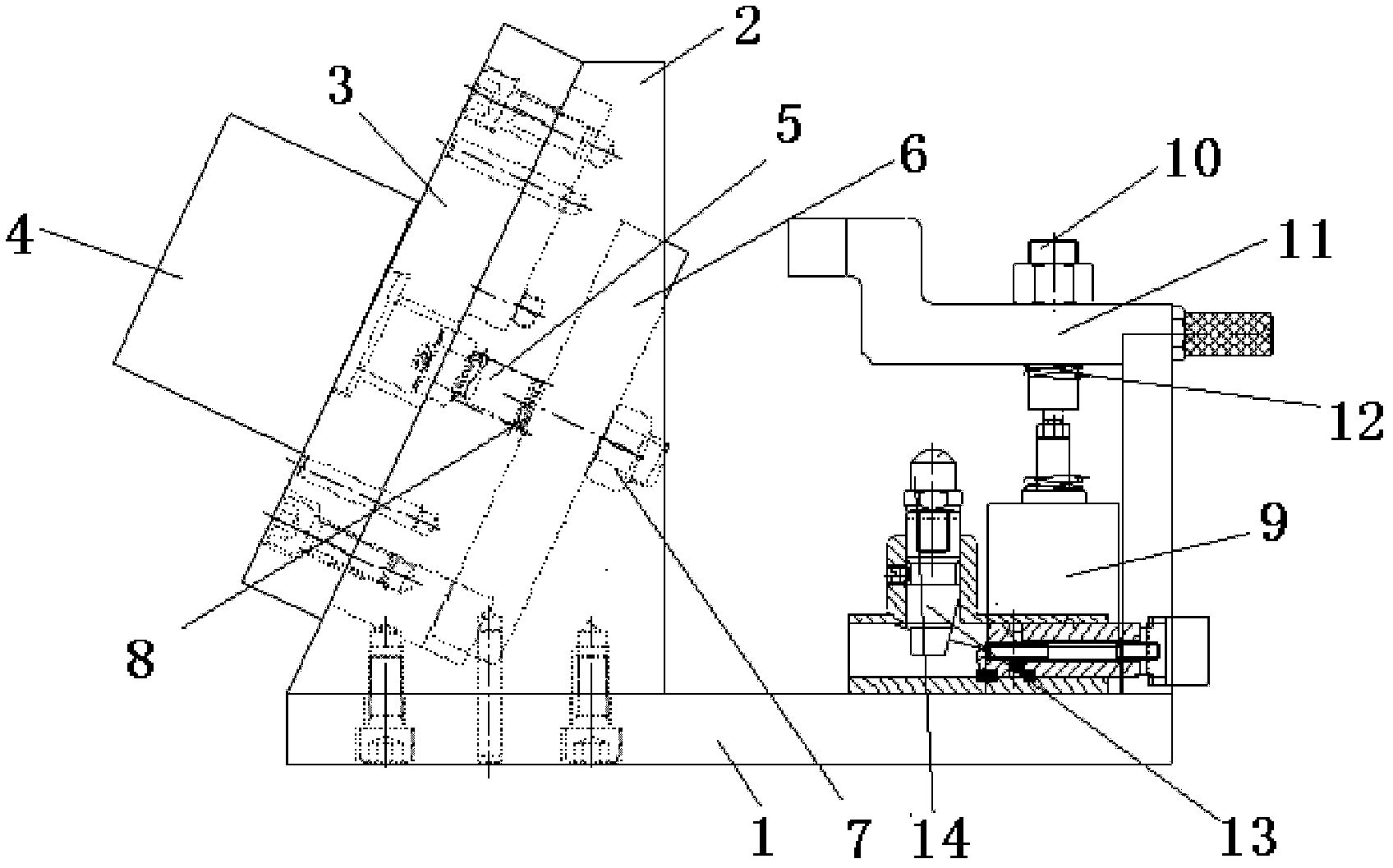

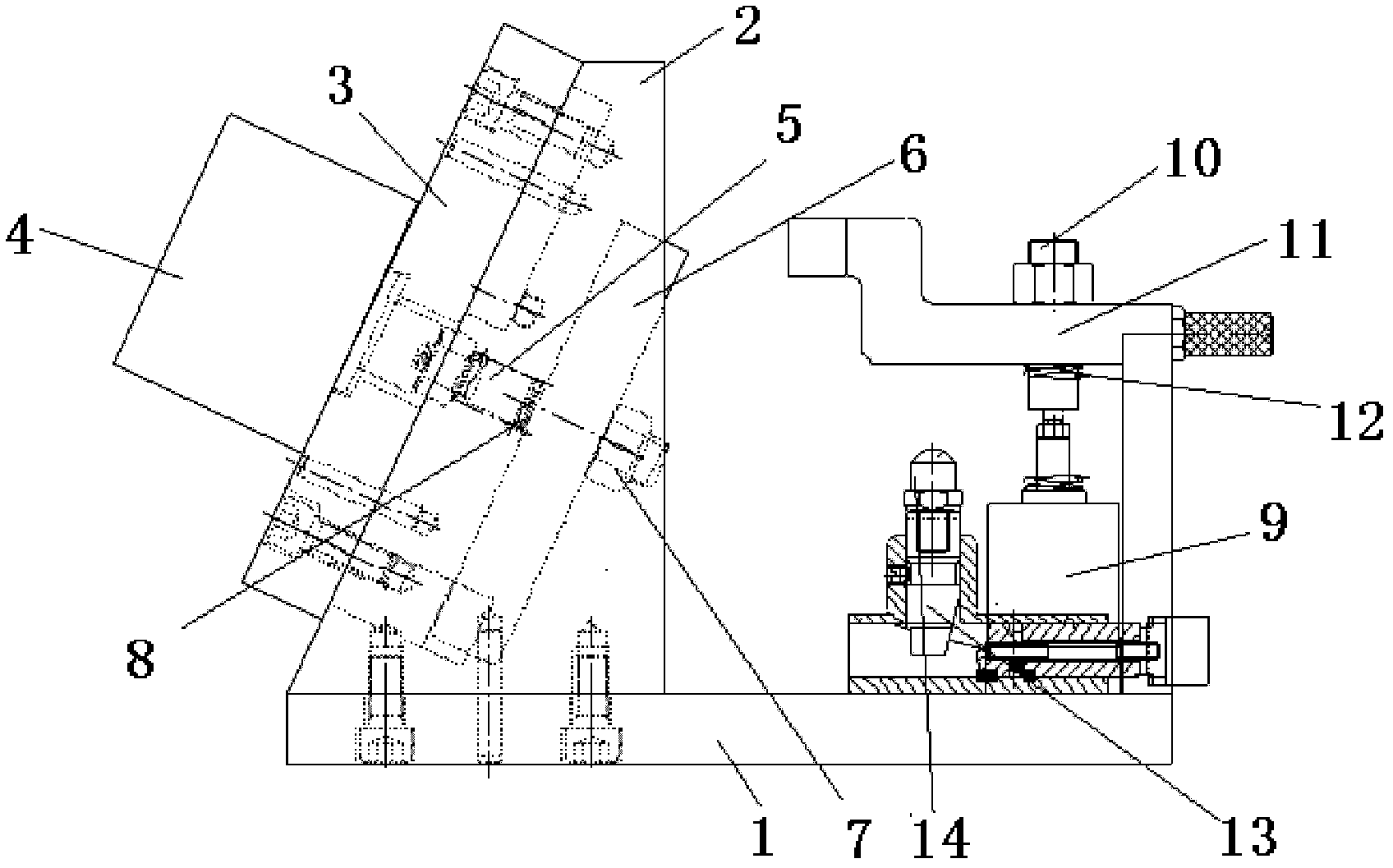

[0009] Referring to the accompanying drawings, a small flange fixture for exhaust pipe milling includes a bottom plate 1, the front and rear ends of the left side of the bottom plate 1 are respectively provided with brackets 2, and the upper left sides of the left and right brackets 2 have slopes respectively. A fixture plate 3 is fixedly installed between the left and right slopes, a thin-walled cylinder 4 is fixedly installed on the outer surface of the fixture plate 3, and a pull rod 5 is fixedly installed on one end of the piston rod of the thin-walled cylinder 4. One end passes through the clamping plate 3 and is equipped with a pressing plate 6. The end of the pull rod 5 is provided with a stop nut 7, and a spring 8 is set on the pulling rod 5, and the spring 8 is pressed between the pressing plate 6 and the clamping plate 3. A cylinder 9 is fixedly installed on the right bottom plate of the support 2, and an upper tie rod 10 is installed on the upper end of the piston ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com