Decoration paster with thermoplastic polyurethane membrane and manufacture method of decoration paster

A technology of polyurethane film and polyurethane, which is applied in decorative arts, chemical instruments and methods, and techniques for producing decorative surface effects, etc., and can solve problems such as difficult fixing of ornaments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Regarding the technology, means and effects used in the present invention, a preferred embodiment is given and described in detail below with drawings, which are for illustration purposes only, and are not limited by this structure in the patent application.

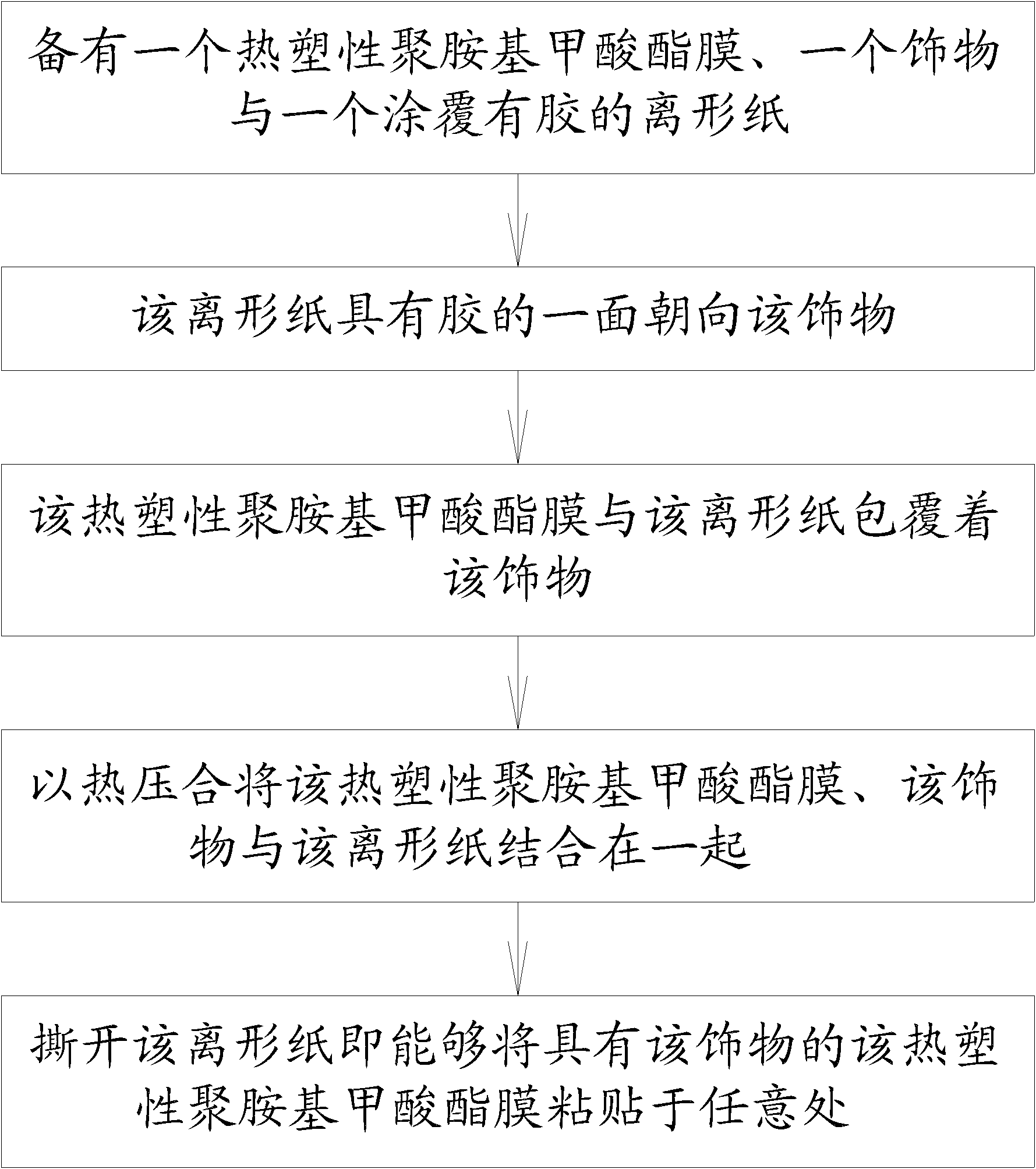

[0032] refer to figure 1 , is a flow chart of the manufacturing method of the decorative patch with thermoplastic polyurethane film of the present invention. A thermoplastic polyurethane (Thermoplastic Polyurethane; TPU) film, a decoration and a release paper coated with glue→the side of the release paper with glue facing the decoration→the thermoplastic polyurethane The ester film and the release paper wrap the decoration→combine the thermoplastic polyurethane film, the decoration and the release paper by heat pressing→tear the release paper to be able to have the The thermoplastic polyurethane film of the ornament is glued anywhere.

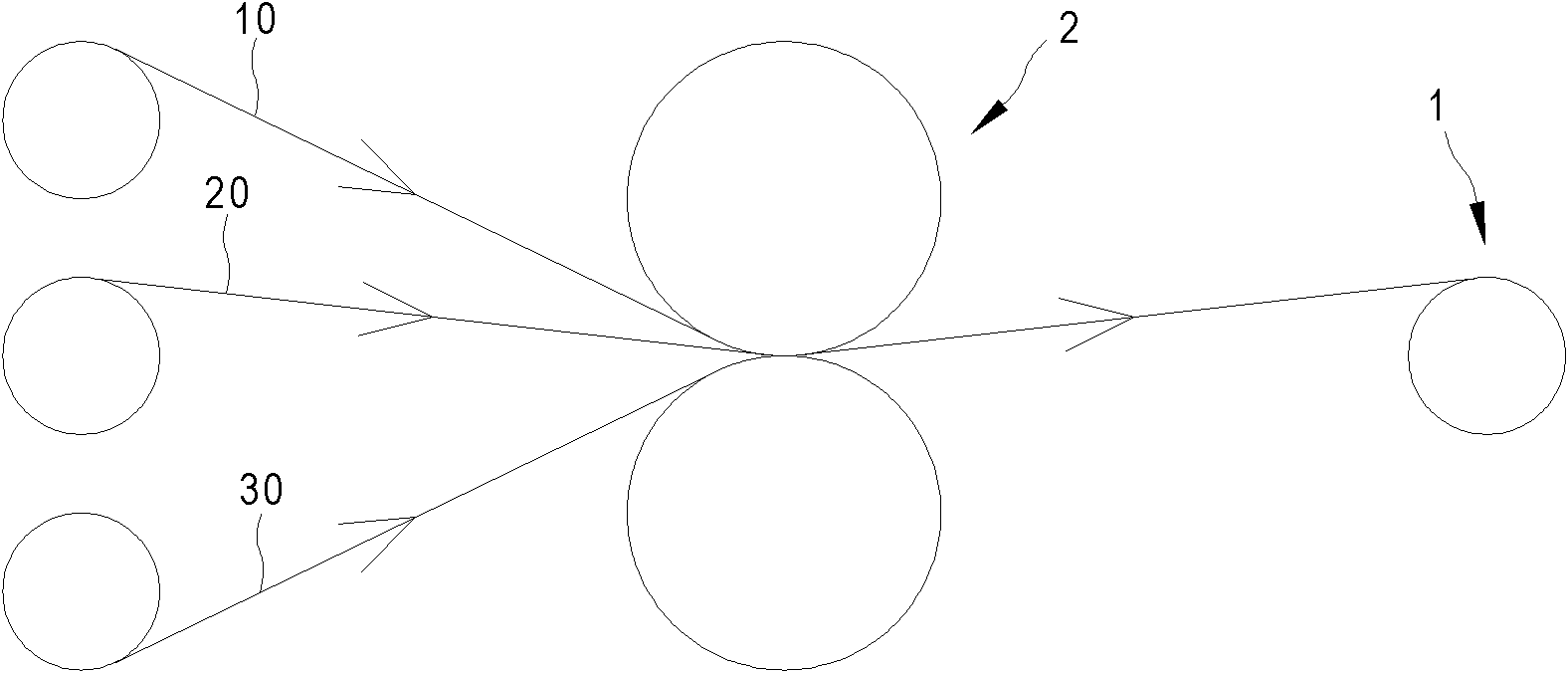

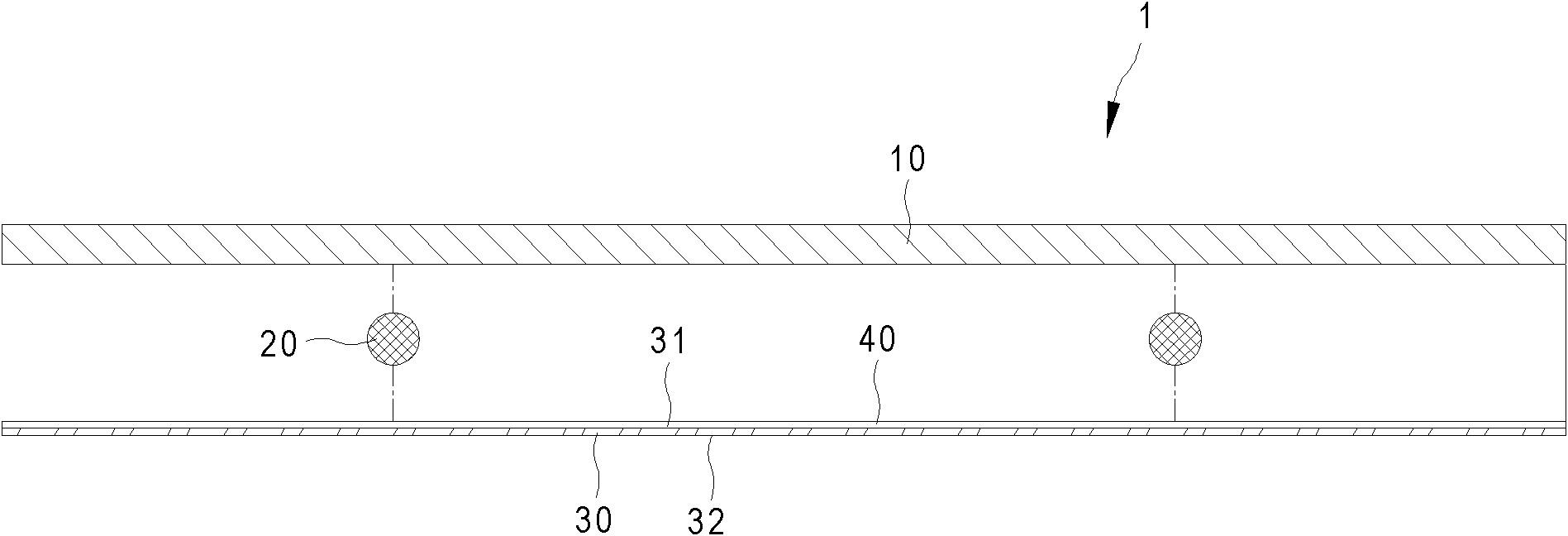

[0033] refer to figure 2 and image 3 , is a hot-pressing schematic diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com