Brake system for a vehicle and method for operating a brake system for a vehicle

A brake system and automobile technology, applied in the direction of hydraulic brake transmission device, brake action activation device, brake, etc., can solve the problems of expensive and troublesome brake system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

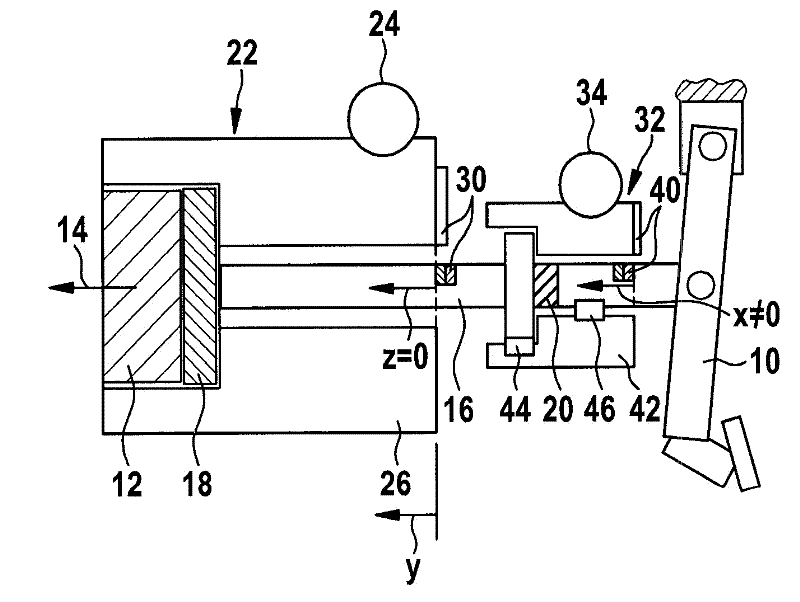

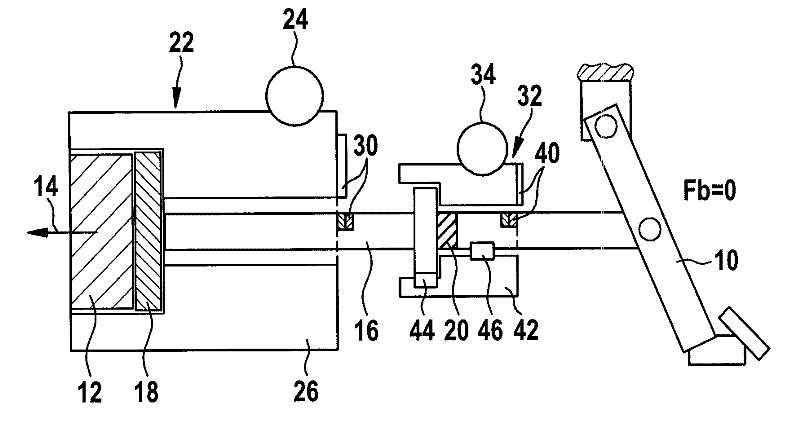

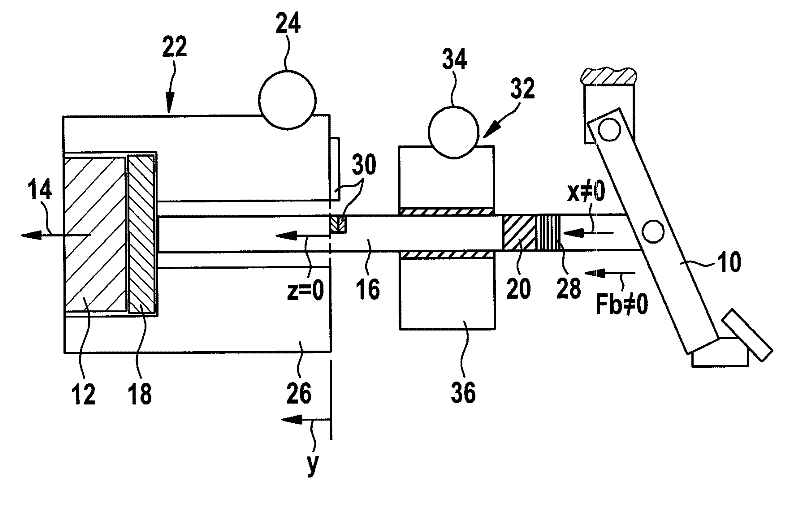

[0016] Figures 1A to 1D A first exemplary embodiment of the brake system is shown schematically in different operating modes.

[0017] exist Figures 1A to 1D The brake system shown only partially in FIG. 2 has a brake actuating element 10 which is formed by a brake pedal. However, the brake system described here is not limited to the formation of brake actuating element 10 by a brake pedal. Alternatively or in addition to the brake pedal, the brake system can also have, for example, a brake actuating element 10 designed for manual actuation.

[0018] For the thus formed vehicle brake, the brake system includes a (not shown) hydraulic brake device having at least one piston-cylinder unit. The output piston 12 is arranged on the piston-cylinder unit in such a way that the internal pressure in the piston-cylinder unit can be increased by adjusting the output piston 12 in the adjustment direction 14 . For this purpose, for example, the output piston 12 can be adjusted at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com