Sliding shoe type self-propelling equipment train for fully mechanized coal faces

A technology for self-moving equipment trains and fully mechanized mining faces, applied to equipment fixed on vehicles, railway car body parts, transportation and packaging, etc., can solve problems such as waste of manpower and material resources, high labor intensity, and potential safety hazards, and achieve Strong integrity, reduce labor intensity and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

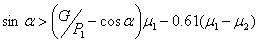

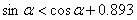

[0024] The fully mechanized working face sliding shoe type self-moving equipment train includes a number of sliding shoe type flatbed cars 1 connected in sequence, the bottom of the sliding shoe type flatbed car 1 is correspondingly provided with a guide push rod 2 connected in sequence, the front end of the sliding shoe type flatbed car 1 and its The rear end of the corresponding guide push rod 2 is provided with a push cylinder 3 that is hinged with the two, and the front end of the sliding shoe flatbed 1 is fixed with a vertical set and a pressing cylinder supported on the corresponding guide push rod 2. 4, and the included angle between the pushing cylinder 3 and the pressing cylinder 4 is less than 84.2°. In the specific implementation process, the base of the sliding shoe flatbed 1 is a sliding shoe, and the cross section of the sliding shoe is an inverted isosceles trapezoid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com